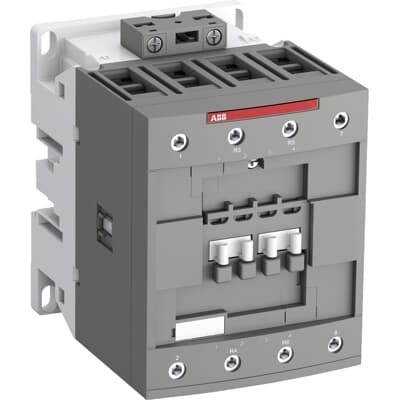

ABB 1SBL391501R8600 Block Contactor - IEC/UL 60947-4-1

Part Number: 1SBL391501R8600

Quick Summary

ABB 1SBL391501R8600 block contactor controls heavy power circuits in manufacturing. End users often struggle with bulky devices that lack compatibility with add-on contact blocks or require complex wiring. This product complies with IEC/EN 60947-4-1, UL 60947-1 and CSA standards, while CE and UKCA declarations support global markets. Its compact 4-pole design and DIN-rail mounting provide a scalable solution for evolving automation needs, enabling quick upgrades without reconfiguring control cabinets. With 400–415 V AC 50 Hz or 415–440 V AC 60 Hz coil voltage, it integrates smoothly into modern control architectures, offering reliable, standards-compliant operation and reduced total cost of ownership for industrial facilities.

Product Information

Extended Description

1SBL391501R8600 ABB: The AFC80-22-00-86 is a 4-pole (2 N.O + 2 N.C) - 1000 V IEC or 600 V UL contactor with Screw terminals, mainly controlling power circuits up to 125 A (IEC AC-1) or 105 A UL general use. Within the AF platform, AFC contactors offer an optimized operating time for AC controlled applications with electromagnetic coil (control voltage : 400 ... 415 V AC 50 Hz / 415 ... 440 V AC 60 Hz). AFC contactors have a block type design and can be easily extended with add-on auxiliary contact blocks and a wide range of additionnal accessories.

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100219C0201 AFC contactors for AC control applications_Catalog PDF

Instructions and Manuals

Installation instructions AF(C)40(B)...80(B)-40/22 Contactors, CA4, CAL4, CAT4, CC4, LDC4 Accessories

Instructions and Manuals (Part 2)

Contactors and Overload relays guide

Product Net Width

90 mm

Product Net Depth / Length

119.5 mm

Product Net Height

116 mm

Product Net Weight

1.45 kg

Number of Main Contacts NO

2

Number of Main Contacts NC

2

Number of Auxiliary Contacts NO

0

Number of Auxiliary Contacts NC

0

Number of Poles

4P

Standards

IEC/EN 60947-1, IEC/EN 60947-4-1, UL 60947-1, UL 60947-4-1, CSA C22.2 No. 60947-1, CSA C22.2 No. 60947-4-1

Rated Operational Voltage

Main Circuit 1000 V

Rated Frequency (f)

Auxiliary Circuit 50 / 60 Hz | Main Circuit 50 / 60 Hz

Conventional Free-air Thermal Current (Ith)

acc. to IEC 60947-4-1, Open Contactors Θ = 40 °C 125 A

Rated Operational Current AC-1 (Ie)

(690 V) 40 °C 125 A | (690 V) 60 °C 105 A | (690 V) 70 °C 90 A

Rated Operational Current AC-3 (Ie)

(415 V) 60 °C 80 A | (440 V) 60 °C 80 A | (500 V) 60 °C 65 A | (690 V) 60 °C 49 A | (1000 V) 60 °C 25 A | (380 / 400 V) 60 °C 80 A | (220 / 230 / 240 V) 60 °C 80 A

Rated Operational Power AC-3 (Pe)

(415 V) 45 kW | (440 V) 45 kW | (500 V) 45 kW | (690 V) 45 kW | (380 / 400 V) 37 kW | (220 / 230 / 240 V) 22 kW

Rated Short-time Withstand Current Low Voltage (Icw)

at 40 °C Ambient Temp, in Free Air, from a Cold State 15 min 140 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 min 300 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 s 1200 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 30 s 450 A

Maximum Breaking Capacity

cos phi=0.45 (cos phi=0.35 for Ie > 100 A) at 440 V 1150 A | cos phi=0.45 (cos phi=0.35 for Ie > 100 A) at 690 V 750 A

Rated Insulation Voltage (Ui)

acc. to IEC 60947-4-1 and VDE 0110 (Gr. C) 1000 V | acc. to UL/CSA 600 V

Rated Impulse Withstand Voltage (Uimp)

Auxiliary Circuit 8 kV

Maximum Electrical Switching Frequency

(AC-1) 600 cycles per hour

Maximum Mechanical Switching Frequency

3600 cycles per hour

Rated Control Circuit Voltage (Uc)

50 Hz 400 ... 415 V | 60 Hz 415 ... 440 V

Coil Consumption

Average Holding Value 50 / 60 Hz 20 V·A | Average Pull-in Value 50 Hz 236 V·A | Average Pull-in Value 60 Hz 260 V·A

Power Loss

at Rated Operating Conditions AC-1 per Pole 8 W | at Rated Operating Conditions AC-3 per Pole 3.2 W

Operate Time

Between Coil De-energization and NC Contact Closing 10 ... 19 ms | Between Coil De-energization and NO Contact Opening 5 ... 16 ms | Between Coil Energization and NC Contact Opening 6 ... 15 ms | Between Coil Energization and NO Contact Closing 7 ... 22 ms

Mounting on DIN Rail

TH35-15 (35 x 15 mm Mounting Rail) acc. to IEC 60715 | TH35-7.5 (35 x 7.5 mm Mounting Rail) acc. to IEC 60715

Mounting by Screws (not supplied)

2 x M4 or 2 x M6 screws placed diagonally

Connecting Capacity Main Circuit

Flexible with Ferrule 1/2x 6 ... 50 mm² | Flexible with Insulated Ferrule 1/2x 6 ... 50 mm² | Rigid 1x 6 ... 70 mm² | Rigid 2x 6 ... 50 mm²

Connecting Capacity Control Circuit

Flexible with Ferrule 1/2x 0.75 ... 2.5 mm² | Flexible with Insulated Ferrule 1x 0.75 ... 2.5 mm² | Flexible with Insulated Ferrule 2x 0.75 ... 1.5 mm² | Rigid 1/2x 1 ... 2.5 mm²

Wire Stripping Length

Control Circuit 10 mm | Main Circuit 17 mm

Degree of Protection

acc. to IEC 60529, IEC 60947-1, EN 60529 Auxiliary Terminals IP20 | acc. to IEC 60529, IEC 60947-1, EN 60529 Coil Terminals IP20 | acc. to IEC 60529, IEC 60947-1, EN 60529 Main Terminals IP10

Recommended Screw Driver

Main Circuit 4 | Main Circuit Hexagon | Control Circuit 5.5 | Control Circuit Slot

Tightening Torque

Control Circuit 1.2 N·m | Main Circuit 6 N·m

Terminal Type

Screw Terminals

Product Name

Block Contactor

Maximum Operating Voltage UL/CSA

Main Circuit 600 V

General Use Rating UL/CSA

(600 V AC) 105 A

Tightening Torque UL/CSA

Control Circuit 11 in·lb | Main Circuit 53 in·lb

Ambient Air Temperature

Close to Contactor for Storage -60 ... +80 °C | Near Contactor for Operation in Free Air -40 ... 70 °C | Near Contactor for Operation in Free Air (0.85 ... 1.1 Uc) -40 ... +60 °C | Near Contactor for Operation in Free Air (Uc) -40 ... 70 °C

Climatic Withstand

Category B according to IEC 60947-1 Annex Q

Maximum Operating Altitude Permissible

Without Derating 3000 m

Pollution Degree

3

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

BV Certificate

BV_2634H36994B1

CB Certificate

CB Certificate AFC80 and AFC96 3-and 4-pole contactors

Declaration of Conformity - CE

EU Declaration of Conformity AFC09 ... AFC80 4-pole Contactors

Declaration of Conformity - UKCA

UK Declaration of Conformity AFC09 ... AFC80 4-pole Contactors

DNV Certificate

DNV Certificate AFC09...96 3-pole & AFC09...80 4-pole contactors with screw, push-in terminals

RINA Certificate

Rina Certificate for AFC09...AFC96 3 pole and 4 pole contactors, NFC relays ,screw and spring terminals

UL Certificate

UL-US Certificate of Compliance AFC40 ... AFC80 4-pole contactors | UL-CA Certificate of Compliance AFC40 ... AFC80 4-pole contactors

Package Level 1 Units

box 1 piece

Package Level 1 Width

146.5 mm

Package Level 1 Depth / Length

97.5 mm

Package Level 1 Height

146.5 mm

Package Level 1 Gross Weight

1.77 kg

Package Level 1 EAN

3471523023550

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4755 >> Contactors

Feature → Business Impact → Application: The 4-pole block contactor design (2 NO + 2 NC) delivers clear, decisive switching for motor control, reducing wiring complexity and simplifying maintenance in assembly lines and packaging systems. This translates to shorter downtime and lower labor costs during commissioning and service windows. Application: Use in conveyors, pumps, and machine tools where precise AC-1 and AC-3 switching is required at 400–415 V or 415–440 V coil voltages, with a maximum main circuit voltage of 1000 V. Feature → Business Impact → Application: Screw terminals and wide connecting capacity (1/2x 6 … 50 mm² flexible; 1x 6 … 70 mm² rigid) enable fast, secure terminations, improving electrical integrity and reducing crimping errors in harsh plant environments. Application: Suitable for high-vibration settings in food processing or packaging lines. Feature → Business Impact → Application: DIN rail mounting TH35-15 or TH35-7.5 plus optional add-on auxiliary contact blocks provides scalable protection and control expansion, supporting future-proof plant design. Application: Ideal for modular automation architectures requiring easy integration with existing control panels. Feature → Business Impact → Application: Coil consumption 20 VA hold and 236–260 VA pull-in, delivering energy-efficient startup and stable control in continuous operation; combined with a low power loss per pole (8 W AC-1, 3.2 W AC-3), it reduces running costs and heat load. Application: Continuous duty machines and HVAC systems where energy efficiency matters. Feature → Business Impact → Application: High short-time withstand current (up to 140 A for 15 minutes, 300 A for 1 minute, 1200 A for 1 second) ensures robustness during startup surges, protecting downstream equipment and reducing nuisance tripping in variable load scenarios. Application: Heavy-duty conveyors and pumps with frequent motor start/stop cycles. Feature → Business Impact → Application: Comprehensive protective ratings (IP20 coil terminals, IP10 main terminals) simplify compliance with safety standards and reduce enclosure costs. Application: Industrial environments with limited protection allowances and space constraints. Feature → Business Impact → Application: Extensive certifications (CE, UKCA, UL, CSA, BV, DNV, RINA) provide confidence for global procurement and multi-site rollouts. Application: Global manufacturing networks requiring regulatory alignment and supplier reliability.

Get a Quick Quote for a ABB 1SBL391501R8600

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SBL391501R8600?

Enquire Now

FAQs

This 4-pole block contactor supports TH35-15 and TH35-7.5 DIN rail mounting for quick panel integration. It also offers screw mounting with 2 x M4 or 2 x M6 screws placed diagonally if DIN rails are unsuitable, ensuring secure, vibration-resistant installations in conveyors, pumps, and machine controls.

For AC-1, rated operational current is up to 125 A at 690 V (60 °C) and 105 A at 690 V (60 °C) with 70 °C limits, while AC-3 ratings include 80 A at 415/440 V and 65 A at 500 V (all at 60 °C). Main circuit voltage can reach 1000 V, with coil voltages 400–415 V (50 Hz) or 415–440 V (60 Hz).

Yes. It is designed for AC-3 duty in motor control with a maximum mechanical switching frequency of 3600 cycles per hour and a maximum electrical switching frequency of 600 cycles per hour, making it suitable for pumps, fans, and conveyors with frequent switching.

The AFC80 family, including this model, carries CE, UKCA, UL, and CSA certifications, along with BV, DNV, and RINA declarations, supporting global procurement and multi-site deployments.

Coil consumption averages 20 VA holding, with pull-in 236–260 VA. The main circuit uses screw terminals with flexible ferrule 1/2x 6–50 mm² or rigid 1x 6–70 mm² connections, enabling fast, secure terminations and reduced field wiring complexity.