Car Lift Conversions

High starting torque for demanding applications. Ideal for car lifts, compressors, conveyors, woodworking machinery, and gearboxes. 0.18kW (0.25hp) to 3.7kW (5hp).

Lathe Motor Conversions

Low starting torque for applications such as pumps, fans, blowers, and ventilation. 0.09kW (0.12hp) to 3.0kW (4hp).

Compressor Conversions

Safe for construction sites and portable equipment where a 110V is mandatory. Ideal for workshops, site tools, and temporary installations.

Send us your enquiry with part numbers or technical requirements.

We'll confirm receipt of enquiry and deliver a detailed quote within 1-2 business days.

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

NEED HELP CHOOSING A SINGLE PHASE MOTOR TO REPLACE YOUR THREE PHASE MOTOR?

Use our quick Motor Selection Wizard to get the right motor first time

Three Phase to Single Phase Motor Conversions

MM Engineering Services specializes in converting three-phase motors to single-phase replacements—and we've successfully done this for thousands of industrial machines, car lifts, lathes, pillar drills, table saws, and workshop equipment.

Unlike generic online forums or mass-market retailers, we understand the specific requirements of each machine type. A conversion solution for a car lift is completely different from a lathe—and we solve both correctly the first time.

When Conversion Makes Sense:

✅ You have single-phase power only (230V) at your premises

✅ Your equipment is three-phase (400V)

✅ You want to avoid the cost of three-phase installation (£2,000-5,000 from your energy supplier)

✅ The equipment is worth keeping (car lifts, high-quality lathes, industrial drills)

When Conversion Doesn't Make Sense

❌ If equipment is already single-phase – no conversion needed

❌ If you're discarding the equipment – not worth the investment

❌ If you have three-phase power available – use it as-is (more efficient)

❌ If multiple three-phase motors need converting – consider three-phase installation instead

Car Lift Conversion - A Complete Guide

- How They Work These motors use two capacitors: a large start capacitor and a smaller run capacitor. At startup, both capacitors are in circuit to create a strong phase shift that produces high starting torque. Once the motor reaches approximately 75% of full speed, a centrifugal switch disconnects the start capacitor, leaving only the run capacitor in circuit for efficient continuous operation.

- Ideal Applications

• Car lifts and vehicle hoists

• Air compressors and refrigeration compressors

• Conveyors and material handling

• Woodworking machinery (saws, planers, thicknessers)

• Gearbox-driven equipment

• Crushers and grinders

• Any application with high starting loads

- Our Range We stock capacitor start/capacitor run motors from 0.18kW (0.25hp) to 3.7kW (5hp) in 2-pole (3000rpm) and 4-pole (1500rpm) configurations. All motors feature high-quality aluminium construction, NSK bearings, IE2 design, complete with Thermal reset switches for added protection and multi-mount design.

Our most popular Car Lift Motors - 2.2kW (3hp) - Hydraulic Driven Car Lifts & 3.7kW (5hp) - Screw/Pulley-Belt Driven Car Lifts

Permanent Capacitor Single Phase Motors

-How They Work A single capacitor remains permanently connected in the motor start winding, providing continuous phase shift. This eliminates the mechanical complexity of a centrifugal switch but limits starting torque to approximately 0.3-0.7 times the rated torque. Once running, permanent capacitor motors are reliable but less efficient than other AC Electric motors.

- Ideal Applications

• Pumps (water, heating, circulation)

• Fans and blowers

• Ventilation systems

• HVAC equipment

• Agricultural fans

• Low-inertia loads

• Equipment with no starting load

-Our Range: We stock permanent capacitor motors from 0.09kW (0.12hp) to 3.0kW (4hp). These motors are perfect for applications where the load starts unloaded (like pumps and fans) and smooth, quiet operation is important.

Our most popular Permanent Capacitor Single Phase Motors

0.75kW | 1500RPM | 80 Frame | 240V Single Phase

1.1kW | 1500RPM | 90 Frame | 240V Single Phase

0.37kW | 1500RPM | 71 Frame | 240V Single Phase

1.5kW | 3000RPM | 90 Frame | 240V Single Phase

Single Phase Motor Speed (RPM) Ratings

Our single phase motors are available in various speeds, ranging from 1000RPM to 3000RPM, covering virtually all domestic, commercial and light industrial applications.

Speed Options

Single phase motors are available in three standard speeds:

- 2-Pole (3000 RPM) – Higher speed, suitable for direct-drive applications like circular saws, pumps, and machinery requiring high rotational speed but have lower torque than a 1500rpm.

- 4-Pole (1500 RPM) – Lower speed with higher torque, ideal for car lifts, gearbox-driven equipment, conveyors, and applications requiring more turning force.

- 6-Pole (1000RPM) - Some applications also use 6-pole (1000 RPM) motors for very high torque requirements.

Single Phase Motor Power Ratings (kW)

Our single phase motors are available in various powers, ranging from 0.09kW (0.12hp) to 3.7kW (5hp), covering virtually all domestic, commercial and light industrial applications.

| Power (kW) | Power (HP) | Typical Applications |

|---|---|---|

| 0.09 - 0.18 | 0.12 - 0.25 | Small fans, pumps, polishing machine. |

| 0.25 - 0.55 | 0.33 - 0.75 | Ventilation fans/blowers, pillar-drills, lathes with clutch systems. |

| 0.75 - 1.5 | 1.0 - 2.0 | Pumps, circular saws, small machinery. |

| 2.2 - 3.7 | 3.0 - 5.0 | 150ltr+ Air compressors, car lifts, log splitters, heavy machinery, industrial equipment. |

Single Phase Motor Frame Sizes Explained

Electric motors come in various frame sizes which determines the physical dimensions of the motor, including the mounting hole positions, shaft height, shaft diameter, length and keyway details. It is essential to match the frame size when replacing an existing motor.

Common Frame Sizes

| Frame | Shaft Height | Typical kW Range |

|---|---|---|

| 56 | 56 mm | 0.09kW (0.12hp) - 0.12kW (0.16hp) |

| 63 | 63 mm | 0.12kW (0.16hp) - 0.18kW (0.25hp) |

| 71 | 71 mm | 0.25kW (0.33hp) - 0.55kW (0.75hp) |

| 80 | 80 mm | 0.55kW (0.75hp) - 1.1kW (1.5hp) |

| 90 | 90mm | 1.1kW (1.5hp) - 2.2kW (3hp) |

| 100 | 100mm | 2.2kW (3hp) - 3.0kW (4.0hp) |

| 112 | 112mm | 3.7kW (5hp) - 4.0kW (5hp) |

Single Phase Motor Mounting Options

All our single phase motors feature multi-mount design with removable feet, allowing flexible installation. Standard mounting options include:

B3 (Foot mounted)

The most common configuration, where the feet are bolted to a base/mounting plate.

B5 (D Flange mounted)

Large flange for mounting direct to equipment. No feet required.

B14 or B14S (Small C Face mounted)

Smaller face flange for compact installation with drilled and tapped holes.

B14L (Large C Face mounted)

Larger face flange for compact installation with drilled and tapped holes.

B34S (Foot & Small C Face mounted)

A combination of a foot mount and a small face mount for a secure fit with maximum flexibility.

B34L (Foot & Large C Face mounted)

A combination of a foot mount and a large face mount for a secure fit with maximum flexibility.

B35 (Foot & D Flange mounted)

Combination mounting with large flange providing both stability on the ground and a direct flange coupling to the driven equipment.

V1 (Vertical Flange mounted with Rain canopy)

Large flange for direct mounting in a vertical position to equipment. No feet required with added protective rain canopy that shields the top of the motor from water ingress, dirt, and debris.

How to wire a Single Phase Motor

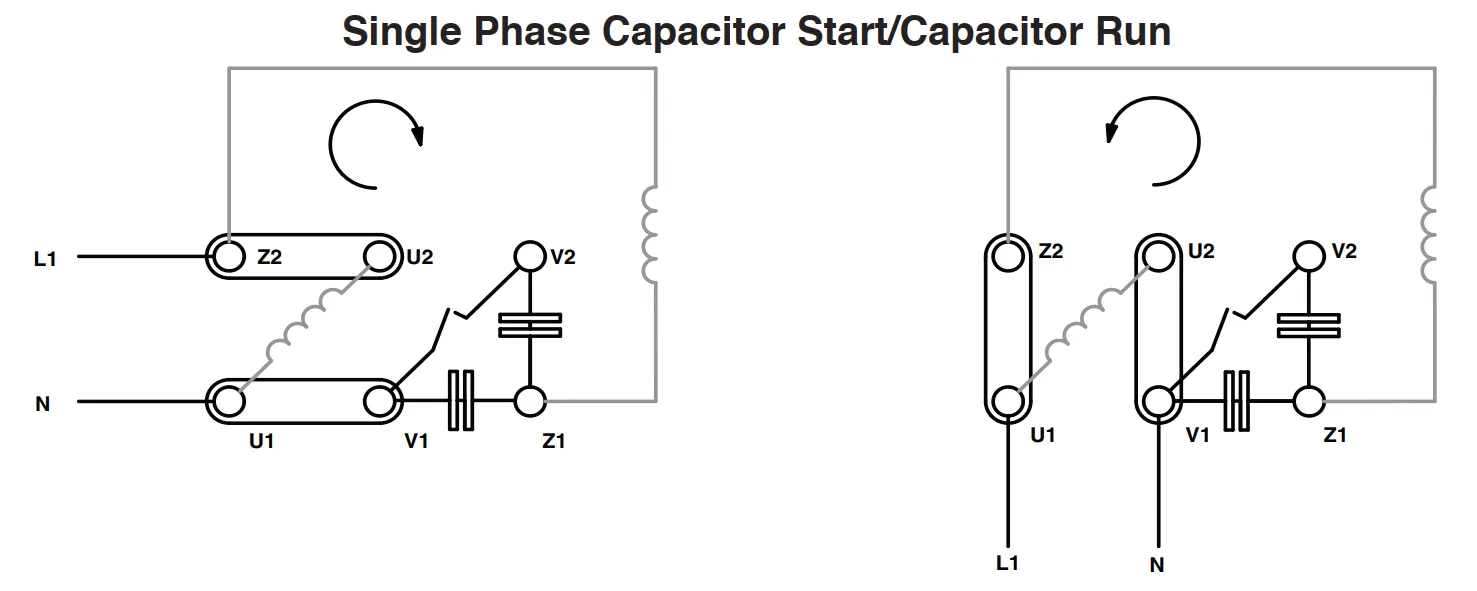

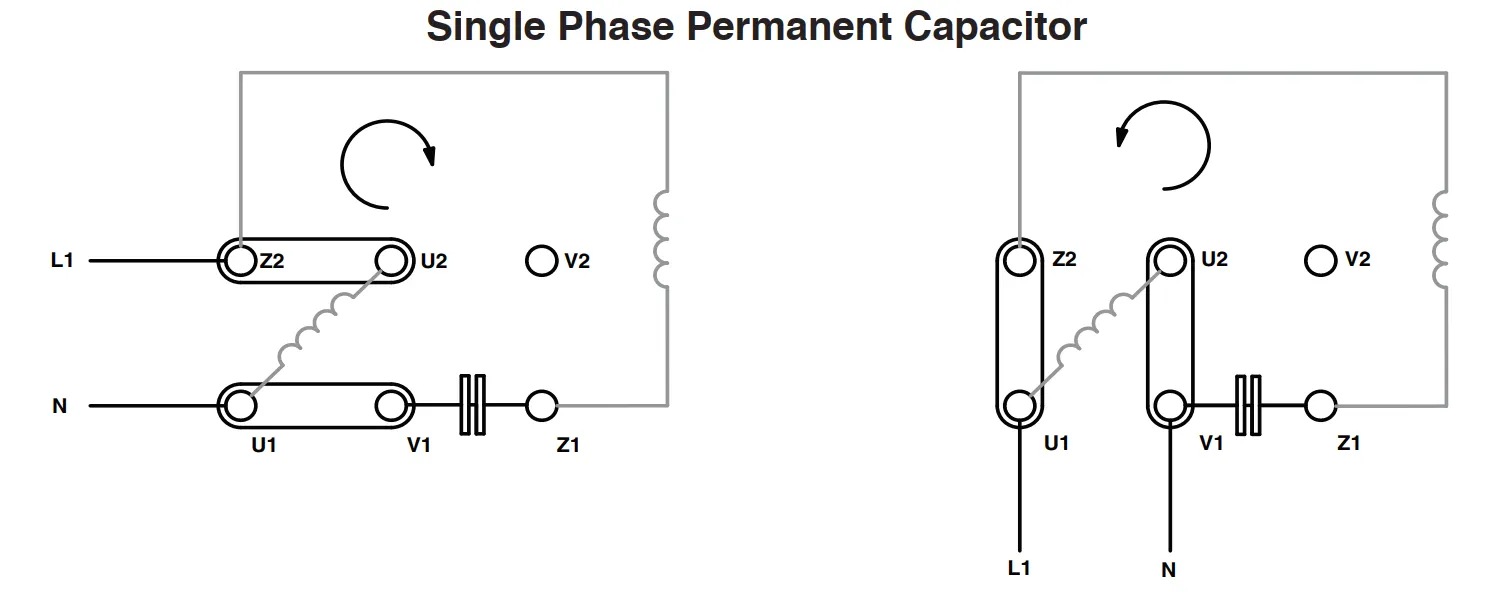

Single phase motors have a terminal box with clearly marked connections. Typically: L (Live), N (Neutral), and E (Earth). The capacitor(s) are usually internally wired. Below is our typical wiring diagrams for a Capacitor Start/Capacitor Run and Permanent Capacitor motor and shows the how to wire the motor for clockwise and anti-clockwise rotation.

Capacitor start/Capacitor Run Motor Wiring Diagram

Permanent Capacitor Motor Wiring Diagram

Single Phase Motor Applications

Single phase motors power equipment across numerous industries and applications:

Agriculture & Farming

• Grain augers and conveyors • Feed mixers • Barn ventilation fans

• Water pumps • Milking pumps

Woodworking & Workshops

• Table saws and band saws • Planers and thicknessers

• Dust extraction • Pillar drills • Lathes

HVAC & Ventilation

HVAC & Ventilation • Extractor fans • Air handling units

Pumps & Water Systems

• Borehole pumps • Pressure boosters • Swimming pool pumps

• Pond pumps • Heating circulation pumps

How to Select the Right Single Phase Motor

Selecting the right single phase motor for your application requires matching several key specifications:

| Specification | Description |

|---|---|

| Power Rating | Match or slightly exceed the power (W/kW/hp) requirement of your application. Check the existing motor nameplate or equipment manual. |

| Speed (Poles) | 2-pole (3000 RPM) for high-speed applications. 4-pole (1500 RPM) for higher torque applications. |

| Frame Size | Measure the existing motor frame size to ensure correct mounting dimensions and shaft height. |

| Motor Type | Capacitor start Capacitor run for high starting torque applications. Permanent capacitor for low starting torque applications. |

| Voltage | 230V for standard UK supply. 110V for construction sites. |

| Mounting Type | B3 foot, B5 flange, B14 face, or combination mounting (B34 foot & face or B35 foot & flange) |

Single Phase vs. Three Phase Electric Motors:

Quick Comparison

| Feature | Single Phase Motor 230V | Three Phase Motor 400V |

|---|---|---|

| Voltage (UK) | 230V/240V | 400V |

| Wiring Connections | Live + Neutral (+ Earth) | L1 + L2 + L3 (+ Earth) |

| Starting Method | Capacitors + Centrifugal Switch | Self-starting |

| Max Power Limit | 3.7kW (5HP) | Almost Unlimited (up to High Voltage) |

| Efficiency | Standard - IE1 & IE2 | High Efficiency (IE3/IE4/IE5) |

| Starting Torque | Medium | High |

| Full Load Torque | Medium | High |

| Variable Speed Control | Not suitable for speed control | Suitable for Speed control |

| Cost | Higher | Lower |

| Typical Use | Home, Domestic, Small workshops | Factories, Large Industrial/Manufacturing sites |

Single Phase vs. Three Phase Electric Motors:

Real World Example (2.2kW)

See below the actual difference between a 2.2kW single phase motor vs a 2.2kW three phase motor

| Feature | Single Phase Motor 230V | Three Phase Motor 400V |

|---|---|---|

| Voltage (UK) | 230V/240V | 400V |

| Power | 2.2kW (3hp) | 2.2kW (3hp) |

| Speed (RPM) | Approx. 2800rpm | Approx. 2800rpm |

| Frame Size | 90L (90mm shaft height) | 90L (90mm shaft height) |

| Wiring Connections | Live + Neutral (+ Earth) | L1 + L2 + L3 (+ Earth) |

| Starting Method | 2 x Capacitors + Centrifugal Switch | DOL Starting |

| Max number of start/stops | 4-6 per hour | 10 per hour |

| Efficiency | IE2 - 83.2% | IE3 - 85.9% |

| Starting Torque | 16.79Nm | 18.74Nm |

| Full Load Torque | 7.3Nm | 7.21Nm |

| Full Load Current | 11.7A | 4.35A |

| Cost | £ 198.10 + VAT | £ 160.56 + VAT |

| Availability | In stock - FREE delivery to UK | In stock - FREE delivery to UK |

FREQUENTLY ASKED QUESTIONS

Standard UK Single phase motors are 230V/240V. For construction sites and safety critical applications, 110V motors are used to reduce shock risk.

Yes you can however it is important to understand a few things. Three phase motors are typically have more torque than a single phase equivalent so we recommend moving up in power. It is also important to note you can switch three phase motors on and off frequently, whereas, with single phase we recommend no more than 4-6 start/stops per hour to allow the capacitors time to discharge otherwise they can overheat causing motor failure.

Easiest way is to check the nameplate of your existing motor, the frame size is found within the model number (e.g. PED 100L, AMAS 90L, ML 80) where the 100, 90 and 80 is the frame size which is the dimension from the centre of the shaft to the base of the shaft. The easiest way to measure/determine the frame size if you have a foot mounted motor is place the motor on a table on its feet, and measure the height from the table to the centre of the shaft.

The number of poles determine the speed of the motor where 2-pole is approximately 3000rpm, 4-pole is approximately 1500rpm, 6-pole is approximately 1000rpm and 8-pole is approximately 750rpm. The slower the speed the more torque.

Yes, our single phase motors meet the new IE2 high efficiency requirements which reduce energy consumption and operating costs compared to the older IE1 motors.

No. Single phase motors are not designed to be used with inverter drives (VFDs) due to them having capacitors and switches. If you need variable speed control, use a 230V/400V three phase motor with a single phase IN/three phase OUT inverter which converts your 230V single phase to a variable frequency three phase output.

All our single phase motors are IP55 rated, meaning they are protected against dust ingress and water jets from any direction. This makes them suitable for most indoor and outdoor applications.

Yes, we offer various modifications including custom shaft lengths, diameters, non-standard mounting options, brake kits, thermistor and anti-condensation heaters. All available on a 2-3 week lead time. Contact us for more information.

The largest single phase motor available is a 3.7kW (5hp). Above this power level, three phase motors are more efficient.

Yes, our experienced motor engineers provide free technical support for motor selection, replacement, troubleshooting. Call or WhatsApp us on 01274 288777 or email sales@mmengservices.co.uk with your enquiry.