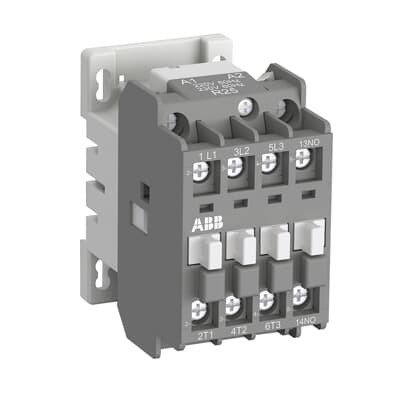

ABB 1SBL921077M2310 Block Contactor - CCC & CQC Certified

Part Number: 1SBL921077M2310

Quick Summary

Block contactor ABB 1SBL921077M2310 for three-phase motor control in industrial drives. Engineers often face reliability, wiring complexity, and space constraints in control panels, and this unit helps simplify installation. It carries CQC and CCC certifications, RoHS and REACH declarations, along with TSCA compliance for global relevance. With a 110V AC coil, block-type design, and built-in auxiliary contact, it delivers robust performance while reducing panel noise, wiring, and downtime—benefiting OEMs and system integrators across manufacturing facilities. This combination supports faster commissioning, easier spare-part planning, and consistent performance across Europe, Asia, and the Americas.

Product Information

Extended Description

1SBL921077M2310 ABB: A2X18 … A2X25 contactors are designed especially for 3-phase motors

Features

- Block type design

- 3 main poles and 1 built-in auxiliary contact

- AC operated control circuit

- Accessories available

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Instructions and Manuals

1SBB902609D3001

Product Net Width

325 mm

Product Net Depth / Length

255 mm

Product Net Height

175 mm

Product Net Weight

31.35 kg

Power Loss

at Rated Operating Conditions AC-1 per Pole 1.1 W

Product Name

Block Contactor

Maximum Operating Altitude Permissible

Without Derating 3000 m

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE Category

Product Not in WEEE Scope

CQC Certificate

CQC Certificate, Contactor, A2X06,A2X09,A2X12,A2X18,A2X25, Made in China

Declaration of Conformity - CCC

CCC Declaration of Conformity, Contactor, A2X06,A2X09,A2X12,A2X18,A2X25, Made in China

Package Level 1 Units

1 piece

Package Level 1 Width

255 mm

Package Level 1 Depth / Length

325 mm

Package Level 1 Height

175 mm

Package Level 1 Gross Weight

12.4 kg

Package Level 1 EAN

3471523016842

Package Level 2 Units

1 piece

Package Level 2 Width

255 mm

Package Level 2 Depth / Length

325 mm

Package Level 2 Height

175 mm

Package Level 2 Gross Weight

12.4 kg

Object Classification Code

Q

ETIM 7

EC000196 - Contactor relay

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4755 >> Contactors

The block-type design with three main poles and a built-in auxiliary contact reduces wiring complexity and panel footprint, speeding installation and simplifying future maintenance. This configuration is particularly advantageous for three-phase motor control in conveyors, pumps, and general machine drive applications, where space and reliability are critical. The coil voltage of 110V AC enables direct integration with standard industrial control circuits and PLC outputs, providing predictable actuation and reducing interface hurdles during system integration. Power loss of 1.1 W per pole means lower heat generation in continuous duty AC-1 operation, translating to cooler panels and longer component life, especially in demanding manufacturing lines. Altitude capability up to 3000 m without derating broadens deployment options for mining, metallurgy, and food processing facilities located at elevation. Regulatory documentation including RoHS II, REACH, TSCA, CQC certificate, and CCC declaration simplifies compliance audits and reduces time-to-production, while the rugged block construction and integrated auxiliary contact improve reliability and simplify spare-part strategies. Compatibility and installation advantages include reduced external relay counts, straightforward mounting, and robust performance under industrial vibration and temperature variations, making it a practical choice for OEMs and system integrators seeking longevity and predictable maintenance cycles.

Get a Quick Quote for a ABB 1SBL921077M2310

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SBL921077M2310?

Enquire Now

FAQs

The ABB 1SBL921077M2310 is a 3-pole block contactor with an AC control coil rated at 110V. It features a block-type footprint with a net width of 325 mm, depth of 255 mm, and height of 175 mm, plus a built-in auxiliary contact for simplified wiring. It is designed for panel mounting and is compatible with standard PLC outputs and relays used in three-phase motor control.

This device operates under AC-1 duty with a low power loss of 1.1 W per pole, contributing to reduced heat in control cabinets. It provides three main poles and one built-in auxiliary contact, delivering reliable switching for three-phase motors while keeping wiring straightforward and installation time short.

Yes, it is rated for operation without derating up to 3000 meters, expanding use in high-altitude facilities. Regulatory compliance is supported by RoHS II and REACH declarations, plus a CQC certificate and CCC declaration of conformity. TSCA declarations further assist cross-regional regulatory adherence, with WEEE not in scope.

The product features a CQC certificate covering relevant ABB contactors and a CCC declaration of conformity. Additional documentation includes RoHS II and REACH declarations and TSCA declarations, ensuring traceability and simplifying regulatory audits for global deployments.

The device combines low power loss, robust block construction, and a built-in auxiliary contact to simplify maintenance and wiring. Reduced heat and fewer spare parts translate to lower energy costs and faster asset commissioning, especially in conveyors, pumps, and HVAC drives, delivering measurable uptime and lifecycle value in manufacturing environments.