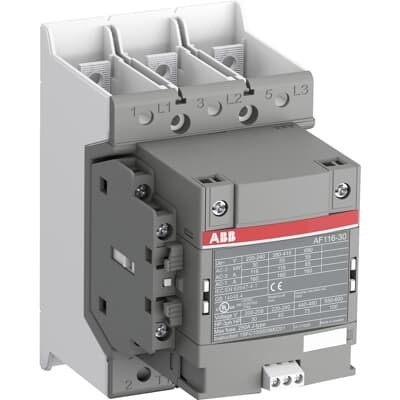

ABB 1SBX214341R1422 Contactor Starter - CE RoHS

Part Number: 1SBX214341R1422

Quick Summary

ABB 1SBX214341R1422 Contactor Starter controls motors in automation lines with integrated contactor and starter block. This compact design reduces panel space and wiring complexity, easing installation and maintenance. It carries CE conformity, cULus recognition, and RoHS compliance, supporting reliable, global deployments. Built for AC-3 service and motor protection integration, it minimizes downtime while maximizing energy efficiency. For engineers and procurement teams, the solution combines robust performance with straightforward installation, compatible with standard motor control schemas and CAD-compatible dimensions. Designed to streamline replacement across existing ABB and third-party motor control panels, it reduces service time and inventory complexity. Its robust mechanical design supports high-duty cycles in harsh industrial environments, helping maintain production continuity.

Product Information

Extended Description

1SBX214341R1422 ABB: AF116R-30-22-14

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100214C0202 - Main catalog Motor protection and control Manual motor starters, contactors and overload relays (PDF) - Edition 2024

CAD Dimensional Drawing

Information - 2D and 3D files for CAD systems

Product Net Width

180 mm

Product Net Depth / Length

126 mm

Product Net Height

177.6 mm

Product Net Weight

4.25 kg

Number of Main Contacts NO

3

Number of Main Contacts NC

0

Number of Auxiliary Contacts NO

2

Number of Auxiliary Contacts NC

2

Power Loss

at Rated Operating Conditions AC-3 per Pole 6 W

Product Name

Contactor Starter

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

cUL Certificate

cULus Certificate, Contactor, AF116-30...AF146-30, AFS116-30...AFS146-30

Declaration of Conformity - CE

CE Declaration of Conformity - Contactor - AF116...AF370

Package Level 1 Gross Weight

5.75 kg

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4755 >> Contactors

Feature → Business Impact → Application: Integrated Contactor Starter reduces panel footprint and wiring complexity, enabling faster panel assembly and easier maintenance, which lowers labor costs in new builds and retrofits for conveyors and process lines. Feature → Application: 3 NO main contacts and 2 NO/2 NC auxiliary contacts provide flexible control logic for multi-drive systems, improving startup sequencing and fault handling in packaging machines and material handling. Feature → Business Impact: 6 W power loss per pole at rated AC-3 supports energy-conscious designs, delivering measurable operating cost reductions over the life of the installation. Feature → Application: 180 mm width, 126 mm depth, and 177.6 mm height with a 4.25 kg net weight offer a balanced footprint for compact switchgear and control panels in tight automation spaces. Feature → Compliance & Installation: CE, cULus, and RoHS declarations simplify regulatory uptime and global deployment, with CAD 2D/3D files available for fast integration into BOMs and engineering drawings. Feature → Application: WEEE and CMRT alignment ensures responsible end-of-life handling and supply chain transparency, beneficial for manufacturers targeting eco-compliant production lines. Feature → Compatibility: ETIM EC000066 and eClass 27371003 classifications aid procurement catalogs and searchable specifications, reducing sourcing time and ambiguity for buyers in electronics and automation. Feature → Reliability: Robust mechanical design and proven performance in AC-3 service support long-running motor control applications, delivering reduced downtime and higher overall equipment effectiveness.

Get a Quick Quote for a ABB 1SBX214341R1422

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SBX214341R1422?

Enquire Now

FAQs

This unit is designed to drop into standard ABB and compatible panel setups. It uses a 3-pole main contact configuration with 2 auxiliary contacts, and its dimensions (180 mm x 126 mm x 177.6 mm) align with common DIN rail and panel mounting schemes. Verify panel clearance and wiring harness compatibility before swap-in to minimize downtime.

The device provides 3 main NO contacts with 0 main NC contacts, plus 2 NO and 2 NC auxiliary contacts. Power loss is rated at 6 W per pole under AC-3 operating conditions. This configuration supports reliable motor switching with flexible control logic and straightforward fault handling.

Yes. With three NO main contacts and appropriate auxiliary contacts, it supports standard 3-phase motor control schemes common in packaging lines, conveyors, and material handling systems. Ensure proper wiring, fault protection, and compatible overload relays are used in the control circuit.

The Contactor Starter carries CE conformity, cULus certification, and RoHS compliance, along with CMRT and WEEE information. These certifications support global deployment, regulatory audits, and sustainable procurement programs, reducing compliance risk for multinational manufacturing sites.

The integrated design reduces panel space and wiring complexity, cutting installation time and field wiring costs. Reduced downtime from reliable AC-3 rated operation, plus easier maintenance due to consolidated components, translates to lower total cost of ownership and improved equipment effectiveness over the motor drive lifecycle.