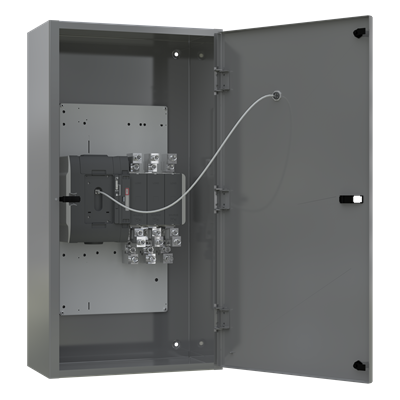

ABB 1SCD014275R1 CGSE DT 800A 3P 240V - UL1008 Certified

Part Number: 1SCD014275R1

Quick Summary

ABB 1SCD014275R1 CGSE DT 800A 3P contactor is designed for 240V AC motor control in industrial panels. Engineers often face downtime from arcing, inrush, and mis-wiring in high-current motor circuits. This device carries UL1008 certification, cULus listing, and ETIM EC000066 compatibility to reinforce compliance and safety in demanding environments. For panel builders and OEMs, the 1-piece MOQ, United States origin, and robust 800 A rating translate into predictable lead times, simplified procurement, and lower total cost of ownership while delivering reliable motor protection. Its compatibility with standard 50/60 Hz mains and US-origin manufacturing supports streamlined integration into new or retrofit projects.

Product Information

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

Instructions and Manuals

ZTGSE and ZTSSE Operation & Maintenance Manual

Wiring Diagram

77A-2006 ZTSSE 30-1200A Electrical Schematic

Minimum Order Quantity

1 piece

Customs Tariff Number

853710

Country of Origin

United States (US)

Package Level 1 Units

crate 1 piece

Controller Type

CG (Level 3)

Neutral Type

Solid Neutral Bar

Number of Poles

3P

Rated Frequency (f)

Main Circuit 50/60 Hz

Rated Operational Voltage

220 ... 240 V AC

Standards

UL1008

Transition Type

Delayed Transition

Ampere Rating

800 A

UL Certificate

cULus - CERTIFICATE OF COMPLIANCE - E535104-Vol1-Sec1-20230619

ETIM 8

EC000066 - Power contactor, AC switching

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

Feature: 3P configuration with a solid neutral bar. Business impact: safer, more reliable switching for three-phase motors in demanding panels. Application: motor control for conveyors, pumps, and machine tools in manufacturing environments. Feature: 800 A ampere rating and 220–240 V AC compatibility. Business impact: accommodates high startup currents and heavy loads with margin, reducing nuisance trips. Application: heavy-duty machinery such as pumps and conveyors in North American facilities. Feature: Delayed Transition. Business impact: soft-start control minimizes inrush energy and mechanical stress, extending contact life. Application: startup sequences for motors in process lines. Feature: UL1008 compliance and cULus listing. Business impact: simplifies panel fabrication and regulatory acceptance, improving time-to-commission. Application: OEM panels and machine tools in North America. Feature: Comprehensive documentation and standards alignment (ETIM EC000066, WEEE 4, Wiring Diagram). Business impact: reduces commissioning risk and ensures end-of-life compliance, enabling predictable maintenance cycles. Application: field installations and service operations. Feature: Compatibility with 50/60 Hz mains and standard North American wiring practices. Business impact: reduces engineering change orders and stocking complexity. Application: retrofit projects and new builds in North America and similar markets. Feature: Compact mounting footprint and flexible terminal arrangements. Business impact: enables retrofits in space-constrained panels and existing switchgear footprints. Application: upgrades in machine enclosures where depth is limited. Feature: Comprehensive service resources and maintenance guidance. Business impact: speeds fault diagnosis and minimizes downtime. Application: field service teams and maintenance planning.

Get a Quick Quote for a ABB 1SCD014275R1

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SCD014275R1?

Enquire Now

FAQs

Install in a suitable industrial enclosure rated for motor control. Follow the 77A-2006 wiring diagram to connect the solid neutral bar and three-phase lines. Ensure supply falls within 220-240 V AC at 50/60 Hz and tighten terminals to the recommended torque to prevent overheating. Use UL 1008 compliant panels and proper clearances.

An 800 A rating provides headroom for motor inrush and peak startup currents, reducing nuisance tripping and protecting downstream equipment. The 3P configuration supports balanced load switching, enhancing electrical reliability in pumps, conveyors, and machine tools while enabling safe isolation during maintenance.

The device carries UL 1008/ cULus certification, ETIM EC000066 classification for power contactors, and WEEE category 4 disposal guidance. It is manufactured in the United States, aligning with North American panel-building standards and regulatory expectations in industrial facilities.

Delayed transition provides a controlled start by softening the inrush surge, reducing electrical and mechanical stress on contacts and motors. This leads to longer contact life, fewer nuisance trips, and improved process uptime for applications like conveyors and pumps with frequent stop‑start cycles.

Expected benefits include lower maintenance at the device level due to fewer startup faults and safer, more predictable operation. The 1-piece MOQ, US origin, and documented manuals help planning and stocking, while UL/cULus compliance supports faster commissioning and a favorable return on investment in industrial automation projects.