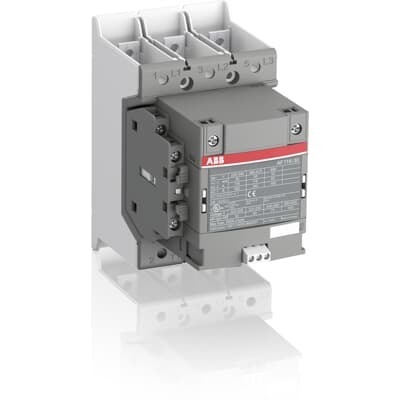

ABB AF116-30-11-33 Contactor - 690V IEC / 600V UL

Part Number: 1SFL427001R3311

Quick Summary

ABB AF116-30-11-33 Contactor is a 3-pole motor starter for 690 V industrial motors. Its wide control voltage range helps tolerate supply variations and reduces panel energy waste. The device carries CE and UL/CSA approvals, with additional CB/CCC and EAC certifications supporting global deployment, making it suitable for standardized manufacturing environments. This block contactor also integrates easily with add-on auxiliary contact blocks and a broad range of accessories, delivering dependable motor protection and control while simplifying panel design and maintenance.

Product Information

Extended Description

1SFL427001R3311 ABB: The AF116-30-11-33 is a 3 pole - 690 V IEC or 600 V UL contactor with pre-mounted auxiliary contacts and double clamp, controlling motors up to 55 kW / 400 V AC (AC-3) or 75 hp / 480 V UL and switching power circuits up to 160 A (AC-1) or 160 A UL general use. Thanks to the AF technology, the contactor has a wide control voltage range (100-250 V 50/60 Hz and DC), managing large control voltage variations, reducing panel energy consumptions and ensuring distinct operations in unstable networks. Furthermore, surge protection is built-in, offering a compact solution. AF contactors have a block type design, can be easily extended with add-on auxiliary contact blocks and an additional wide range of accessories.

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100214C0202 - Main catalog Motor protection and control Manual motor starters, contactors and overload relays (PDF) - Edition 2024

Data Sheet, Technical Information (Part 2)

Contactors and Overload relays guide

Instructions and Manuals

Operating instruction, Contactor, AF(S)116, AF140, AF(S)146

CAD Dimensional Drawing

Information - 2D and 3D files for CAD systems

Product Net Width

90 mm

Product Net Depth / Length

142.5 mm

Product Net Height

150 mm

Product Net Weight

1.55 kg

Number of Main Contacts NO

3

Number of Main Contacts NC

0

Number of Auxiliary Contacts NO

1

Number of Auxiliary Contacts NC

1

Number of Poles

3P

Rated Operational Voltage

Main Circuit 690 V

Rated Frequency (f)

Main Circuit 60 Hz

Conventional Free-air Thermal Current (Ith)

acc. to IEC 60947-4-1, Open Contactors Θ = 40 °C 160 A

Rated Operational Current AC-1 (Ie)

(690 V) 40 °C 160 A | (690 V) 60 °C 145 A | (690 V) 70 °C 130 A

Rated Operational Current AC-3 (Ie)

(415 V) 55 °C 116 A | (440 V) 55 °C 116 A | (500 V) 55 °C 110 A | (690 V) 55 °C 65 A | (380 / 400 V) 55 °C 116 A | (220 / 230 / 240 V) 55 °C 116 A

Rated Operational Current AC-3e (Ie)

(415 V) 60 °C 116 A | (440 V) 60 °C 116 A | (500 V) 60 °C 110 A | (690 V) 60 °C 65 A | (380 / 400 V) 60 °C 116 A | (220 / 230 / 240 V) 60 °C 116 A

Rated Operational Power AC-3 (Pe)

(415 V) 55 kW | (440 V) 75 kW | (500 V) 75 kW | (690 V) 55 kW | (380 / 400 V) 55 kW | (220 / 230 / 240 V) 30 kW

Rated Operational Power AC-3e (Pe)

(415 V) 55 kW | (440 V) 75 kW | (500 V) 75 kW | (690 V) 55 kW | (380 / 400 V) 55 kW | (220 / 230 / 240 V) 30 kW

Rated Breaking Capacity AC-3

8 x Ie AC-3

Rated Breaking Capacity AC-3e

8.5 x Ie AC-3e

Rated Making Capacity AC-3

10 x Ie AC-3

Rated Making Capacity AC-3e

12 x Ie AC-3e

Short-Circuit Protective Devices

gG Type Fuses 250 A

Rated Short-time Withstand Current Low Voltage (Icw)

at 40 °C Ambient Temp, in Free Air, from a Cold State 10 s 928 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 15 min 160 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 min 379 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 s 1160 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 30 s 536 A

Rated Insulation Voltage (Ui)

acc. to IEC 60947-4-1 and VDE 0110 (Gr. C) 1000 V | acc. to UL/CSA 600 V

Rated Impulse Withstand Voltage (Uimp)

8 kV

Maximum Electrical Switching Frequency

(AC-1) 300 cycles per hour | (AC-2 / AC-4) 150 cycles per hour | (AC-3) 300 cycles per hour

Mechanical Durability

5 million

Maximum Mechanical Switching Frequency

300 cycles per hour

Coil Operating Limits

(acc. to IEC 60947-4-1) Uc (at θ ≤ 70 °C)

Rated Control Circuit Voltage (Uc)

50 Hz 100 ... 250 V | 60 Hz 100 ... 250 V | DC Operation 100 ... 250 V

Coil Consumption

Holding at Max. Rated Control Circuit Voltage 50 Hz 6 V·A | Holding at Max. Rated Control Circuit Voltage 60 Hz 6 V·A | Pull-in at Max. Rated Control Circuit Voltage 50 Hz 130 V·A | Pull-in at Max. Rated Control Circuit Voltage 60 Hz 130 V·A | Pull-in at Max. Rated Control Circuit Voltage DC 135 W

Power Loss

at Rated Operating Conditions per Pole 6 W

Operate Time

Between Coil De-energization and NO Contact Opening 37 ... 47 ms | Between Coil Energization and NO Contact Closing 25 ... 55 ms

Degree of Protection

acc. to IEC 60529, IEC 60947-1, EN 60529 Auxiliary Terminals IP40

Terminal Type

Double Clamp

Product Name

Block Contactor

General Use Rating UL/CSA

(600 V AC) 160 A

Horsepower Rating UL/CSA

(200 ... 208 V AC) Three Phase 15 Hp | (200 V AC) Three Phase 30 hp | (208 V AC) Three Phase 30 hp | (220 ... 240 V AC) Three Phase 20 Hp | (220 ... 240 V AC) Three Phase 40 hp | (440 ... 480 V AC) Three Phase 40 Hp | (440 ... 480 V AC) Three Phase 75 hp | (550 ... 600 V AC) Three Phase 50 Hp | (550 ... 600 V AC) Three Phase 100 hp

Ambient Air Temperature

Close to Contactor Fitted with Thermal O/L Relay (0.85 ... 1.1 Uc) -25 ... 55 °C | Close to Contactor without Thermal O/L Relay (0.85 ... 1.1 Uc) -40 ... 70 °C | Close to Contactor for Storage -40 ... 70 °C

Maximum Operating Altitude Permissible

Without Derating 3000 m

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

ABB EcoSolutions

Yes

ABB Site Meeting Group Waste To Landfill Target

Non-hazardous waste is sent to a landfill, where there is no alternative option available within 100km of a facility

End Of Life Disassembling Instructions

End-of-life instruction - AF(S)116(B)-**(RT) to AF(S)205(B)-**(RT)

Environmental Product Declaration - EPD

Environmental Product Declaration, AF(S)116-AF(S)146 (SE) Contactors

Improved Energy Efficiency for Customers

Product Efficiency - Product requires less energy to operate compared to similar product on market or older products from the same line

Recyclability Rate of the Product acc. to EN45555

Design for Closing Resource Loops - Standard EN45555 - 87.8 %

Sustainable Material Content in Product (wt. %)

Recycled Metal - 37 %

A2L Certificate – UL

UL Certificate of Compliance A2L, Contactor, AF116 - AF146

ABS Certificate

ABS Approval, Contactor, AF116 ... AF370 (Sweden)

BV Certificate

BV Certificate, Contactor, AF116-30 ... AF370-30...AF116-40...AF370-40

CB Certificate

SEMKO_SE-70479M1

CCS Certificate

CCS Certificate, Contactor, AF116 to AF2850 (Sweden)

CQC Certificate

CQC Certificate, AC Contactor, AF116-*-*-*, AF140-*-*-*, AF146-*-*-*, AF116B-*-*-*, AF140B-*-*-*, AF146B-*-*-*, AFS116-30-*-*,AFS140-30-*-*, AFS146-30-*-*, Made in Sweden

Declaration of Conformity - CCC

CCC Declaration of Conformity, AC Contactor, AF116-*-*-*, AF140-*-*-*, AF146-*-*-*, AF116B-*-*-*, AF140B-*-*-*, AF146B-*-*-*, AFS116-30-*-*,AFS140-30-*-*, AFS146-30-*-*, Made in Sweden

Declaration of Conformity - CE

CE Declaration of Conformity - Contactor - AF116...AF370

Declaration of Conformity - UKCA

UK Declaration of Conformity - Contactors >100A

DNV Certificate

DNV-certificate, Contactors, AF116-30...AF370-30 and AF116-40...AF370-40

EAC Certificate

9AKK107046A8618

LR Certificate

Lloyds register Certificate, Contactor, AF116-30 ... AF370-30, AF116-40...AF370-40

PRS Certificate

PRS Certificate - AF116...AF1650

RINA Certificate

RINA Certificate, AF95, AF110, AF145, AF185, AF210, AF260, AF300, AF400, AF460, AF580, AF750, AF1250, AF1350, AF1650, AF2050, AF2650, AF116, AF140, AF146, AF190, AF205, AF265, AF305, AF370

RMRS Certificate

9AKK107045A6978

UL Certificate

cULus Certificate, Contactor, AF116-30...AF146-30, AFS116-30...AFS146-30

UL Listing Card

UL_E36588

Package Level 1 Units

box 1 piece

Package Level 1 Width

207 mm

Package Level 1 Depth / Length

216 mm

Package Level 1 Height

150 mm

Package Level 1 Gross Weight

1.75 kg

Package Level 1 EAN

7320500478516

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4758 >> Iec Contactors

E-Number (Finland)

3707484

E-Number (Sweden)

3210527

Feature → Business Impact → Application: The AF116-30-11-33 uses AF technology, delivering a wide control voltage range of 100–250 V AC/DC, which reduces control-system energy draw and stabilizes operation in networks with voltage fluctuation. This translates to lower energy costs and improved process reliability for conveyors and pumps in continuous-operation facilities. Feature → Business Impact → Application: Built-in surge protection and a compact block design reduce panel space and component count, enabling easier cabinet layout and faster commissioning for water treatment and packaging lines. Feature → Business Impact → Application: Three main contacts plus one NO and one NC auxiliary contact provide versatile control logic, supporting both motor and line-side switching in diverse automation scenarios. Feature → Business Impact → Application: Double clamp terminals and 90 mm width offer robust, vibration-tolerant wiring in harsh industrial environments, ideal for rugged installations in metalworking and mining facilities. Feature → Business Impact → Application: Rated for AC-1 and AC-3 applications with high current ratings (Ie) and defined P<?>, ensuring compliant motor-start sequences for fans, pumps, and compressors in industrial plants. Feature → Business Impact → Application: Wide compatibility with accessories and extension options allows seamless lifecycle expansion, reducing downtime when upgrading control schemes or increasing motor capacity.

Get a Quick Quote for a ABB 1SFL427001R3311

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SFL427001R3311?

Enquire Now

FAQs

The device provides three main contacts (NO), plus one NO and one NC auxiliary contact. It uses Double Clamp terminals for secure wiring and has a compact 90 mm width, enabling straightforward integration into standard control panels and easy expansion with accessory contact blocks.

For AC-1 operation at 690 V, Ie is up to 160 A (40 °C). For AC-3 operation, Ie is 65 A at 690 V (or 116 A at lower voltages such as 380/400 V in 55 °C environments). These values support starting and running of motors like fans, pumps, and conveyors under typical industrial loads.

The contactor carries CE, UL/CSA, and CB/CCC declarations and certificates, along with EAC-related approvals. This mix supports global deployment, regulatory compliance in diverse markets, and reliability in safety-critical motor control applications.

Coil control voltage ranges from 100 to 250 V for both AC and DC operations (50/60 Hz). Holding current is 6 VA and pull-in current is 130 VA at 50/60 Hz, with DC pull-in at 135 W. This broad range reduces panel power fluctuations and supports reliable actuation across varying supply conditions.

With built-in surge protection, AF technology for wide voltage tolerance, and a compact design that minimizes cabinet footprint, the AF116-30-11-33 lowers energy waste, reduces installation time, and minimizes downtime during maintenance or retrofits. Its compatibility with add-on accessories also simplifies lifecycle upgrades and maintains consistent performance across diverse industrial processes.