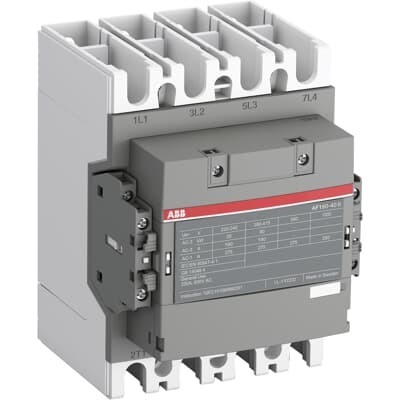

ABB AF190-40-22-12 Contactor - 275 A, UL/CSA Listed

Part Number: 1SFL487102R1222

Quick Summary

ABB AF190-40-22-12 Contactor is a four-pole motor starter for 90 kW motors at 400 V AC. Common panel energy waste from control voltage fluctuations is mitigated by its wide control voltage range of 48-130 V AC/DC, ensuring stable operation in networks with voltage variation. It carries CE and UL/CSA listings, along with UKCA and EAC certifications, supporting global compliance and simplifying cross-border deployment. The AF technology delivers a compact, surge-protected solution that integrates easily with pre-mounted auxiliary contacts and main circuit bars. This combination reduces panel space, speeds installation, and improves motor uptime in demanding manufacturing and process environments.

Product Information

Extended Description

1SFL487102R1222 ABB: The AF190-40-22-12 is a 4 pole - 1000 V IEC or 600 V UL contactor with pre-mounted auxiliary contacts and Main Circuit Bars, controlling motors up to 90 kW / 400 V AC (AC-3) / and switching power circuits up to 275 A (AC-1) or 230 A UL general use. Thanks to the AF technology, the contactor has a wide control voltage range (48-130 V 50/60 Hz and DC), managing large control voltage variations, reducing panel energy consumptions and ensuring distinct operations in unstable networks. Furthermore, surge protection is built-in, offering a compact solution. AF contactors have a block type design, can be easily extended with add-on auxiliary contact blocks and an additional wide range of accessories.

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100214C0202 - Main catalog Motor protection and control Manual motor starters, contactors and overload relays (PDF) - Edition 2024

Data Sheet, Technical Information (Part 2)

Contactors and Overload relays guide

Instructions and Manuals

Operating instruction, Contactor, AF(S)190 ... AF(S)370

CAD Dimensional Drawing

Information - 2D and 3D files for CAD systems

Dimension Diagram

Dimension Drawing. Contactor,AF190,AF205

Product Net Width

140 mm

Product Net Depth / Length

153 mm

Product Net Height

196 mm

Product Net Weight

3.3 kg

Number of Main Contacts NO

4

Number of Main Contacts NC

0

Number of Auxiliary Contacts NO

2

Number of Auxiliary Contacts NC

2

Number of Poles

4P

Rated Operational Voltage

Main Circuit 1000 V

Rated Frequency (f)

Main Circuit 60 Hz

Conventional Free-air Thermal Current (Ith)

acc. to IEC 60947-4-1, Open Contactors Θ = 40 °C 275 A

Rated Operational Current AC-1 (Ie)

(1000 V) 40 °C 250 A | (1000 V) 55 °C 225 A | (1000 V) 60 °C 225 A | (1000 V) 70 °C 185 A | (690 V) 40 °C 275 A | (690 V) 55 °C 250 A | (690 V) 60 °C 250 A | (690 V) 70 °C 200 A

Rated Operational Current AC-3 (Ie)

(415 V) 55 °C 190 A | (440 V) 55 °C 190 A | (380 / 400 V) 55 °C 190 A | (220 / 230 / 240 V) 55 °C 190 A

Rated Operational Power AC-3 (Pe)

(415 V) 90 kW | (440 V) 110 kW | (380 / 400 V) 90 kW | (220 / 230 / 240 V) 55 kW

Rated Breaking Capacity AC-3

8 x Ie AC-3

Rated Making Capacity AC-3

10 x Ie AC-3

Short-Circuit Protective Devices

gG Type Fuses 355 A

Rated Short-time Withstand Current Low Voltage (Icw)

at 40 °C Ambient Temp, in Free Air, from a Cold State 10 s 1520 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 15 min 275 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 min 621 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 s 1900 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 30 s 878 A

Maximum Breaking Capacity

cos phi=0.45 (cos phi=0.35 for Ie > 100 A) at 440 V 3300 A

Rated Insulation Voltage (Ui)

acc. to IEC 60947-4-1 and VDE 0110 (Gr. C) 1000 V | acc. to UL/CSA 1000 V

Rated Impulse Withstand Voltage (Uimp)

Main Circuit 8 kV

Maximum Electrical Switching Frequency

(AC-1) 300 cycles per hour

Mechanical Durability

5 million

Maximum Mechanical Switching Frequency

300 cycles per hour

Coil Operating Limits

(acc. to IEC 60947-4-1) 0.85 x Uc Min. ... 1.1 x Uc Max. (at θ ≤ 70 °C)

Rated Control Circuit Voltage (Uc)

50 Hz 48 ... 130 V | 60 Hz 48 ... 130 V | DC Operation 48 ... 130 V

Coil Consumption

Holding at Max. Rated Control Circuit Voltage 50 Hz 4 V·A | Holding at Max. Rated Control Circuit Voltage 60 Hz 4 V·A | Holding at Max. Rated Control Circuit Voltage DC 2.5 W | Pull-in at Max. Rated Control Circuit Voltage 50 Hz 180 V·A | Pull-in at Max. Rated Control Circuit Voltage 60 Hz 180 V·A | Pull-in at Max. Rated Control Circuit Voltage DC 150 W

Power Loss

15 W | at Rated Operating Conditions per Pole 15 W

Operate Time

Between Coil De-energization and NO Contact Opening 45 ... 80 ms | Between Coil Energization and NO Contact Closing 25 ... 60 ms

Connecting Capacity Main Circuit

Flexible 2 x 50 ... 95 mm² | Rigid Al-Cable 1 x 95 ... 185 mm² | Rigid Cu-Cable 2 x 50 ... 120 mm²

Connecting Capacity Auxiliary Circuit

Flexible with Ferrule 2x 0.75 ... 2.5 mm² | Flexible with Insulated Ferrule 2x 0.75 ... 2.5 mm² | Flexible 1x0.75 ... 2.5 mm² | Solid 2 x 1 ... 4 mm² | Stranded 1 x 1 .... 4 mm²

Degree of Protection

acc. to IEC 60529, IEC 60947-1, EN 60529 Coil Terminals IP20 | acc. to IEC 60529, IEC 60947-1, EN 60529 Main Terminals IP00

Tightening Torque

Cable Lug 18 N·m | Main Circuit 14 ... 31 N·m

Terminal Type

Main Circuit: Bars

Product Name

Block Contactor

Maximum Operating Voltage UL/CSA

Main Circuit 1000 V

General Use Rating UL/CSA

(1000 V AC) 250 A

Horsepower Rating UL/CSA

(200 ... 208 V AC) Three Phase 20 Hp | (200 V AC) Three Phase 50 hp | (208 V AC) Three Phase 50 hp | (220 ... 240 V AC) Three Phase 25 Hp | (220 ... 240 V AC) Three Phase 60 hp | (440 ... 480 V AC) Three Phase 60 Hp | (440 ... 480 V AC) Three Phase 125 hp | (550 ... 600 V AC) Three Phase 75 Hp | (550 ... 600 V AC) Three Phase 150 hp

Ambient Air Temperature

Close to Contactor Fitted with Thermal O/L Relay (0.85 ... 1.1 Uc) -25 ... 50 °C | Close to Contactor without Thermal O/L Relay (0.85 ... 1.1 Uc) -40 ... 70 °C | Close to Contactor for Storage -40 ... 70 °C

Maximum Operating Altitude Permissible

Without Derating 3000 m

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

ABB EcoSolutions

Yes

ABB Site Meeting Group Waste To Landfill Target

Non-hazardous waste is sent to a landfill, where there is no alternative option available within 100km of a facility

End Of Life Disassembling Instructions

End-of-life instruction - AF(S)116(B)-**(RT) to AF(S)205(B)-**(RT)

Environmental Product Declaration - EPD

Environmental Product Declaration, AF190-AF205 (SE) Contactors

Improved Energy Efficiency for Customers

Product Efficiency - Product requires less energy to operate compared to similar product on market or older products from the same line

Recyclability Rate of the Product acc. to EN45555

Design for Closing Resource Loops - Standard EN45555 - 79.2 %

Sustainable Material Content in Product (wt. %)

Recycled Metal - 35 %

ABS Certificate

ABS Approval, Contactor, AF116 ... AF370 (Sweden)

BV Certificate

BV Certificate, Contactor, AF116-30 ... AF370-30...AF116-40...AF370-40

CB Certificate

SE-82315

CQC Certificate

CQC Certificate, AC Contactor, AF190-*-*-*, AF205-*-*-*, AF190B-*-*-*, AF205B-*-*-*, AFS190-30-*-*, AFS205-30-*-*, Made in Sweden

Declaration of Conformity - CCC

CCC Declaration of Conformity, AC Contactor, AF190-*-*-*, AF205-*-*-*, AF190B-*-*-*, AF205B-*-*-*, AFS190-30-*-*, AFS205-30-*-*, Made in Sweden

Declaration of Conformity - CE

CE Declaration of Conformity - Contactor - AF116B...RT to AF370B...RT

Declaration of Conformity - UKCA

UK Declaration of Conformity - Contactors >100A

EAC Certificate

9AKK107046A8618

LR Certificate

Lloyds register Certificate, Contactor, AF116-30 ... AF370-30, AF116-40...AF370-40

PRS Certificate

PRS Certificate - AF116...AF1650

RINA Certificate

RINA Certificate, AF95, AF110, AF145, AF185, AF210, AF260, AF300, AF400, AF460, AF580, AF750, AF1250, AF1350, AF1650, AF2050, AF2650, AF116, AF140, AF146, AF190, AF205, AF265, AF305, AF370

RMRS Certificate

9AKK107045A6978

UL Certificate

cULus Certificate, Contactor, AF190-40, AF205-40 (4-pole)

Package Level 1 Units

box 1 piece

Package Level 1 Width

166 mm

Package Level 1 Depth / Length

238 mm

Package Level 1 Height

180 mm

Package Level 1 Gross Weight

3.9 kg

Package Level 1 EAN

7320500504253

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4758 >> Iec Contactors

E-Number (Finland)

3707184

Feature: Wide control voltage range 48-130 V AC/DC. Business Impact: Enables stable coil operation across fluctuating networks, reducing nuisance tripping and energy waste. Application: Suitable for AC-3 motor control of pumps, fans, and conveyors with variable supply conditions. Feature: Built-in surge protection and AF block design. Business Impact: Increases reliability and reduces the need for external protection devices, lowering panel complexity and total cost of ownership. Application: Ideal for modular installations with add-on auxiliary contact blocks. Feature: High current and power ratings. Business Impact: Supports motors up to 90 kW and main circuit currents up to 275 A UL general use, enabling compact drives for demanding applications. Application: Industrial machines and process lines requiring robust switching at 415–440 V. Feature: 4 main NO contacts and 2 NO + 2 NC auxiliary contacts. Business Impact: Flexible control circuits and interlocking options, improving control logic and safety interlocks. Application: Complex sequencing in conveyors and automated lines. Feature: Robust life and mechanical durability. Business Impact: 5 million mechanical operations and 300 cycles per hour reduce maintenance intervals and downtime. Application: High-availability manufacturing cells and continuous operation environments. Feature: Modular compatibility and installation advantages. Business Impact: Pre-mounted main circuit bars and manageable torque specs streamline installation and future upgrades. Application: Quick panel integration with standard torque ranges and accessible wiring.

Get a Quick Quote for a ABB 1SFL487102R1222

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SFL487102R1222?

Enquire Now

FAQs

For AC-3, the contactor provides 190 A at 415 V (and 440 V), enabling up to 90 kW motor power at 415 V. For AC-1, it supports up to 250 A at 1000 V (and related voltages). The device is rated for 1000 V insulation, 60 Hz operation, and 8 kV impulse withstand, supporting reliable switching in demanding drives.

Yes. The AF190-40-22-12 is UL/cULus listed and CE certified, with UKCA and EAC declarations available for broader market compliance. These certifications help ensure safe, compliant installation in North American, European, and other global facilities.

The coil accepts 48–130 V AC, 50/60 Hz, or DC, enabling stable coil operation despite supply variations. This reduces coil fatigue, minimizes false tripping, and lowers energy use in fluctuating electrical networks, which translates to improved uptime and lower maintenance costs in automated lines.

Main circuit connections use bars with flexible 2x50-95 mm² and rigid Cu/Al options, tightened to 14–31 N·m. Auxiliary circuits support 0.75–2.5 mm² ferrule cables or 1–4 mm² solids. Plan room for torque values and ensure compatible cables, as improper torque or cable sizing can affect contact performance and reliability.

The AF190-40-22-12 offers up to 5 million mechanical cycles and a maximum mechanical switching frequency of 300 cycles per hour. With built-in surge protection and modular accessories, you can expect reduced maintenance intervals, lower spare-part costs, and higher availability in continuous operations such as packaging lines or pumping systems.