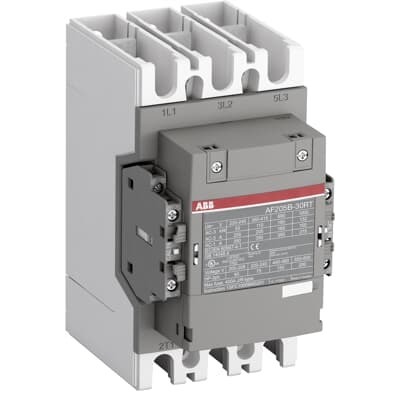

ABB 1SFL527062R1122 Block Contactor - IEC 60947-4-1

Part Number: 1SFL527062R1122

Quick Summary

Block Contactor ABB 1SFL527062R1122 provides reliable motor control for large industrial motors in manufacturing lines. Engineers often contend with voltage fluctuations and panel energy waste that erode uptime and raise operating costs. This AF technology-based device complies with IEC/EN 60947-4-1 and UL 60947-4-1, with CE/UKCA and other certificates supporting safe, global operation. By combining a wide control voltage range with integrated surge protection, it enables compact, energy-efficient panels while offering modular add-on auxiliary blocks for future expansion. In practice, you gain predictable third-party compliance and straightforward maintenance, helping procurement minimize risk and total cost of ownership.

Product Information

Extended Description

1SFL527062R1122 ABB: The AF205B-30-22RT-11 is a 3 pole - 1000 V IEC or 600 V UL contactor with pre-mounted auxiliary contacts and ring tongue ferrules, controlling motors up to 110 kW / 400 V AC (AC-3) or 150 hp / 480 V UL and switching power circuits up to 350 A (AC-1) or 300 A UL general use. Thanks to the AF technology, the contactor has a wide control voltage range (24-60 V 50/60 Hz and 20-60 V DC), managing large control voltage variations, reducing panel energy consumptions and ensuring distinct operations in unstable networks. Furthermore, surge protection is built-in, offering a compact solution. AF contactors have a block type design, can be easily extended with add-on auxiliary contact blocks and an additional wide range of accessories.

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100214C0202 - Main catalog Motor protection and control Manual motor starters, contactors and overload relays (PDF) - Edition 2024

Data Sheet, Technical Information (Part 2)

Contactors and Overload relays guide

Instructions and Manuals

Operating instruction, Contactor, AF(S)190 ... AF(S)370

CAD Dimensional Drawing

Information - 2D and 3D files for CAD systems

Product Net Width

105 mm

Product Net Depth / Length

152 mm

Product Net Height

196 mm

Product Net Weight

2.4 kg

Number of Main Contacts NO

3

Number of Main Contacts NC

0

Number of Auxiliary Contacts NO

2

Number of Auxiliary Contacts NC

2

Number of Poles

3P

Standards

IEC/EN 60947-1, IEC/EN 60947-4-1, UL 60947-4-1, CSA C22.2 No. 60947-4-1, IEC 60077-1 (applicable parts), IEC 60077-2 (applicable parts), EN 50155 (applicable parts), TR CU 001/2011, IEC 61373, For compliance confirmation on applicable parts based on your application and combination, please consult your ABB sales representatives.

Rated Operational Voltage

Main Circuit 1000 V

Rated Operational Current AC-1 (Ie)

(1000 V) 40 °C 275 A | (1000 V) 60 °C 250 A | (1000 V) 70 °C 200 A | (690 V) 40 °C 350 A | (690 V) 60 °C 300 A | (690 V) 70 °C 240 A

Rated Operational Current AC-3 (Ie)

(415 V) 55 °C 205 A | (440 V) 55 °C 205 A | (500 V) 55 °C 165 A | (690 V) 55 °C 165 A | (1000 V) 55 °C 100 A | (380 / 400 V) 55 °C 205 A | (220 / 230 / 240 V) 55 °C 205 A

Rated Operational Current DC-1 (Ie)

(100 V) 1 Pole, 40 °C 350 A | (100 V) 1 Pole, 60 °C 300 A | (100 V) 1 Pole, 70 °C 240 A | (110 V) 2 Poles in Series, 40 °C 350 A | (110 V) 2 Poles in Series, 60 °C 300 A | (110 V) 2 Poles in Series, 70 °C 240 A | (110 V) 3 Poles in Series, 40 °C 350 A | (110 V) 3 Poles in Series, 60 °C 300 A | (110 V) 3 Poles in Series, 70 °C 240 A | (175 V) 2 Poles in Series, 40 °C 350 A | (175 V) 2 Poles in Series, 60 °C 300 A | (175 V) 2 Poles in Series, 70 °C 240 A | (200 V) 2 Poles in Series, 40 °C 350 A | (200 V) 2 Poles in Series, 60 °C 300 A | (200 V) 2 Poles in Series, 70 °C 240 A | (220 V) 3 Poles in Series, 40 °C 350 A | (220 V) 3 Poles in Series, 60 °C 300 A | (220 V) 3 Poles in Series, 70 °C 240 A | (260 V) 3 Poles in Series, 40 °C 350 A | (260 V) 3 Poles in Series, 60 °C 300 A | (260 V) 3 Poles in Series, 70 °C 240 A | (300 V) 3 Poles in Series, 40 °C 350 A | (300 V) 3 Poles in Series, 60 °C 300 A | (300 V) 3 Poles in Series, 70 °C 240 A | (72 V) 1-Pole, 40 °C 350 A | (72 V) 1-Pole, 60 °C 300 A | (72 V) 1-Pole, 70 °C 240 A | (72 V) 2 Poles in Series, 40 °C 350 A | (72 V) 2 Poles in Series, 60 °C 300 A | (72 V) 2 Poles in Series, 70 °C 240 A | (72 V) 3 Poles in Series, 40 °C 350 A | (72 V) 3 Poles in Series, 60 °C 300 A | (72 V) 3 Poles in Series, 70 °C 240 A | (90 V) 1 Pole, 40 °C 350 A | (90 V) 1 Pole, 60 °C 300 A | (90 V) 1 Pole, 70 °C 240 A

Rated Operational Current DC-3 (Ie)

(110 V) 2 Poles in Series, 40 °C 275 A | (110 V) 2 Poles in Series, 60 °C 275 A | (110 V) 2 Poles in Series, 70 °C 240 A | (110 V) 3 Poles in Series, 40 °C 275 A | (110 V) 3 Poles in Series, 60 °C 275 A | (110 V) 3 Poles in Series, 70 °C 240 A | (220 V) 3 Poles in Series, 40 °C 275 A | (220 V) 3 Poles in Series, 60 °C 275 A | (220 V) 3 Poles in Series, 70 °C 240 A | (72 V) 2 Poles in Series, 40 °C 275 A | (72 V) 2 Poles in Series, 60 °C 275 A | (72 V) 2 Poles in Series, 70 °C 240 A | (72 V) 3 Poles in Series, 40 °C 275 A | (72 V) 3 Poles in Series, 60 °C 275 A | (72 V) 3 Poles in Series, 70 °C 240 A

Rated Operational Current DC-5 (Ie)

(110 V) 2 Poles in Series, 40 °C 275 A | (110 V) 2 Poles in Series, 60 °C 275 A | (110 V) 2 Poles in Series, 70 °C 240 A | (110 V) 3 Poles in Series, 40 °C 275 A | (110 V) 3 Poles in Series, 60 °C 275 A | (110 V) 3 Poles in Series, 70 °C 240 A | (220 V) 3 Poles in Series, 40 °C 275 A | (220 V) 3 Poles in Series, 60 °C 275 A | (220 V) 3 Poles in Series, 70 °C 240 A | (72 V) 2 Poles in Series, 40 °C 275 A | (72 V) 2 Poles in Series, 60 °C 275 A | (72 V) 2 Poles in Series, 70 °C 240 A | (72 V) 3 Poles in Series, 40 °C 275 A | (72 V) 3 Poles in Series, 60 °C 275 A | (72 V) 3 Poles in Series, 70 °C 240 A

Rated Operational Power AC-3 (Pe)

(415 V) 110 kW | (440 V) 132 kW | (500 V) 110 kW | (690 V) 160 kW | (1000 V) 132 kW | (380 / 400 V) 110 kW | (220 / 230 / 240 V) 55 kW

Rated Short-time Withstand Current Low Voltage (Icw)

at 40 °C Ambient Temp, in Free Air, from a Cold State 10 s 1640 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 15 min 350 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 min 670 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 s 2050 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 30 s 947 A

Rated Insulation Voltage (Ui)

acc. to UL/CSA 1000 V

Mechanical Durability

5 million

Maximum Mechanical Switching Frequency

300 cycles per hour

Rated Control Circuit Voltage (Uc)

50 Hz / 60 Hz 24 ... 60 V | DC Operation 20 ... 60 V

Coil Consumption

Holding at Max. Rated Control Circuit Voltage 50 Hz 6 V·A | Holding at Max. Rated Control Circuit Voltage 60 Hz 6 V·A | Pull-in at Max. Rated Control Circuit Voltage 50 Hz 165 V·A | Pull-in at Max. Rated Control Circuit Voltage 60 Hz 165 V·A | Pull-in at Max. Rated Control Circuit Voltage DC 205 W

Power Loss

8 W | at Rated Operating Conditions per Pole 8 W

Terminal Type

Main Circuit: Bars

Product Name

Block Contactor

General Use Rating UL/CSA

(1000 V AC) 275 A

Horsepower Rating UL/CSA

(200 ... 208 V AC) Three Phase 60 hp | (220 ... 240 V AC) Three Phase 75 hp | (440 ... 480 V AC) Three Phase 150 hp | (550 ... 600 V AC) Three Phase 200 hp

Full Load Amps Motor Use

(200 ... 208 V AC) Three Phase 177 A | (220 ... 240 V AC) Three Phase 192 A | (440 ... 480 V AC) Three Phase 180 A | (550 ... 600 V AC) Three Phase 192 A

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

End Of Life Disassembling Instructions

End-of-life instruction - AF(S)116(B)-**(RT) to AF(S)205(B)-**(RT)

A2L Certificate – UL

UL Certificate of Compliance A2L, Contactor, AF190 - AF370

CB Certificate

SE-82315

CQC Certificate

CQC Certificate, AC Contactor, AF190-*-*-*, AF205-*-*-*, AF190B-*-*-*, AF205B-*-*-*, AFS190-30-*-*, AFS205-30-*-*, Made in Sweden

Declaration of Conformity - CCC

CCC Declaration of Conformity, AC Contactor, AF190-*-*-*, AF205-*-*-*, AF190B-*-*-*, AF205B-*-*-*, AFS190-30-*-*, AFS205-30-*-*, Made in Sweden

Declaration of Conformity - CE

CE Declaration of Conformity - Contactor - AF116B...RT to AF370B...RT

Declaration of Conformity - UKCA

UK Declaration of Conformity - Contactors >100A - Rail application

EAC Certificate

9AKK107046A8618

UR Certificate

cURus certificate, Contactor, AF190B..RT - AF205B-30...RT

Package Level 1 Units

box 1 piece

Package Level 1 Width

160 mm

Package Level 1 Depth / Length

258 mm

Package Level 1 Height

235 mm

Package Level 1 Gross Weight

3 kg

Package Level 1 EAN

7320500510322

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4758 >> Iec Contactors

Feature: 3-pole design with 3 main NO contacts and 2 NO / 2 NC auxiliary contacts, block-type construction, and compatibility with add-on auxiliary blocks. Business Impact: Enables compact, scalable motor control for multi-motor lines while preserving signaling flexibility. Application: Ideal for 3-phase motors up to 110 kW at 400 V AC and higher power levels at 690–1000 V, with room for future expansion. Feature: AF technology delivering a wide control voltage range of 24–60 V AC (50/60 Hz) and 20–60 V DC. Business Impact: Reduces panel energy consumption and tolerates control voltage variations in unstable networks. Application: Suitable for plants with variable supply or switching servo drives and other control systems. Feature: Built-in surge protection. Business Impact: Improves longevity of the coil and contacts, minimizing protection panels and maintenance costs. Application: Critical in environments with power quality issues or frequent voltage transients. Feature: Pre-mounted auxiliary contacts and ring tongue ferrules. Business Impact: Simplifies wiring, lowers assembly time, and reduces field wiring errors. Application: Fast installation in control cabinets and retrofits in existing lines. Feature: Mechanical durability and switching performance. Business Impact: 5 million mechanical cycles and up to 300 cycles per hour support high-demand applications with predictable life. Application: Reliable operation in conveyors, pumps, and press lines. Feature: High-current capability and versatile voltage ratings. Business Impact: Meets diverse motor protection and control needs from 1000 V main circuit operations to 275 A AC-1 and 165 A AC-3 at higher voltages. Application: Suitable for global OEM setups across industrial automation and power control installations.

Get a Quick Quote for a ABB 1SFL527062R1122

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SFL527062R1122?

Enquire Now

FAQs

The 1SFL527062R1122 uses main circuit bars for wiring and supports a block-type design with pre-mounted auxiliary contacts. Wiring is streamlined by the included auxiliary blocks and compatible terminal arrangements. For installation, ensure the device is mounted in a control cabinet with adequate clearance, connect the main circuits to the bars, and wire the coil to 24–60 VAC or 20–60 VDC per your control system.

For AC-1, the device supports up to 275 A at 1000 V, 250 A at 1000 V at higher temperatures, and 350 A at 690 V for certain conditions. For AC-3, it offers up to 165 A at 690–1000 V and up to 205 A in some 415–440 V ranges. These values make the contactor suitable for starting and switching motor loads in industrial settings.

Yes. With 3P main contacts, 2 NO/2 NC auxiliary contacts, a wide control voltage range, built-in surge protection, and AF technology, the contactor is well-suited for conveyors, pumps, and other machinery subject to voltage variation. The robust mechanical durability and rated switching capability support frequent cycling typical in material handling and fluid systems.

The device complies with IEC/EN 60947-1 and 60947-4-1, UL 60947-4-1, and CSA equivalents, plus CE and UKCA markings. It also carries EAC and other declarations. These certifications help ensure safe operation, regulatory compliance, and acceptance in global installations across industrial automation and power distribution.

The AF technology design delivers up to 5 million mechanical cycles and a maximum mechanical switching frequency of 300 cycles per hour, reducing maintenance intervals. Coil consumption is optimized for energy efficiency, with separate pull-in and holding values. This results in improved uptime, predictable performance, and lower total cost of ownership in high-demand automation.