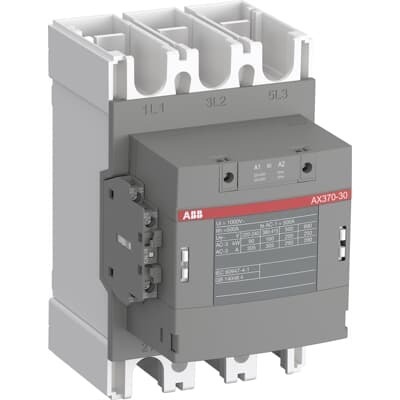

ABB 1SFL607074R8111 Block Contactor - UL Certified

Part Number: 1SFL607074R8111

Quick Summary

Block Contactor ABB 1SFL607074R8111 is a rugged 3P device designed for reliable motor control in 690 V systems. This solution minimizes downtime by delivering fast, repeatable switching for high-inertia motors and demanding loads. The unit is CE- and UL-certified, RoHS and REACH-compliant, and compatible with ABB’s motor protection and control ecosystem, ensuring smooth integration with 24 V control circuits. Designed for ambient temperatures from -25 to 55 °C and up to 3,000 m altitude, it supports challenging factory environments. With a compact footprint and robust mechanical durability, this product delivers predictable performance, straightforward installation, and favorable total cost of ownership in industrial automation projects.

Product Information

Extended Description

1SFL607074R8111 ABB: AX370-30-11-81 Contactor

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100214C0202 - Main catalog Motor protection and control Manual motor starters, contactors and overload relays (PDF) - Edition 2024

Instructions and Manuals

1SFC101062M0201_E

CAD Dimensional Drawing

Information - 2D and 3D files for CAD systems

Product Net Width

140 mm

Product Net Depth / Length

180 mm

Product Net Height

225 mm

Product Net Weight

4.7 kg

Number of Main Contacts NO

3

Number of Main Contacts NC

0

Number of Auxiliary Contacts NO

1

Number of Auxiliary Contacts NC

1

Number of Poles

3P

Rated Operational Voltage

Main Circuit 1000 V

Rated Frequency (f)

Main Circuit 60 Hz

Conventional Free-air Thermal Current (Ith)

acc. to IEC 60947-4-1, Open Contactors Θ = 40 °C 250 A

Rated Operational Current AC-1 (Ie)

(690 V) 40 °C 600 A | (690 V) 55 °C 500 A | (690 V) 70 °C 400 A

Rated Operational Current AC-3 (Ie)

(415 V) 55 °C 370 A | (440 V) 55 °C 370 A | (500 V) 55 °C 315 A | (690 V) 55 °C 315 A | (380 / 400 V) 55 °C 370 A | (220 / 230 / 240 V) 55 °C 370 A

Rated Operational Power AC-3 (Pe)

(415 V) 200 kW | (440 V) 200 kW | (500 V) 250 kW | (690 V) 315 kW | (380 / 400 V) 200 kW | (220 / 230 / 240 V) 110 kW

Rated Breaking Capacity AC-3

8 x Ie AC-3

Rated Making Capacity AC-3

10 x Ie AC-3

Rated Short-time Withstand Current Low Voltage (Icw)

at 40 °C Ambient Temp, in Free Air, from a Cold State 10 s 2960 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 15 min 600 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 min 1208 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 s 3700 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 30 s 1709 A

Rated Insulation Voltage (Ui)

acc. to IEC 60947-4-1 and VDE 0110 (Gr. C) 690 V

Rated Impulse Withstand Voltage (Uimp)

8 kV

Maximum Electrical Switching Frequency

300 cycles per hour

Mechanical Durability

5 million

Maximum Mechanical Switching Frequency

300 cycles per hour

Coil Operating Limits

(acc. to IEC 60947-4-1) Uc (at θ ≤ 70 °C)

Rated Control Circuit Voltage (Uc)

50 Hz 24 V | 60 Hz 24 V

Power Loss

at Rated Operating Conditions per Pole 27 W

Degree of Protection

acc. to IEC 60529, IEC 60947-1, EN 60529 Auxiliary Terminals IP40

Terminal Type

Main Circuit: Bars

Product Name

Block Contactor

Ambient Air Temperature

Close to Contactor Fitted with Thermal O/L Relay (0.85 ... 1.1 Uc) -25 ... 55 °C | Close to Contactor without Thermal O/L Relay (0.85 ... 1.1 Uc) -40 ... 70 °C | Close to Contactor for Storage -40 ... 70 °C

Maximum Operating Altitude Permissible

Without Derating 3000 m

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

CQC Certificate

CQC Certificate, Contactor, AX260, AX300, AX370, Made in China

Declaration of Conformity - CCC

CCC Declaration of Conformity, Contactor, AX260, AX300, AX370, Made in China

Declaration of Conformity - CE

CE Declaration of conformity - Contactor - AX95...AX370

UL Certificate

cULus Certificate, Contactor, AF265, AF305, AF370, AX260, AX300, AX370, AFS265, AFS305, AFS370

Package Level 1 Units

box 1 piece

Package Level 1 Width

175 mm

Package Level 1 Depth / Length

270 mm

Package Level 1 Height

223 mm

Package Level 1 Gross Weight

5.4 kg

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4755 >> Contactors

The 3P block contactor design provides three normally open main contacts plus one NO auxiliary and one NC auxiliary contact, enabling integrated control and signaling with a single device, which reduces wiring complexity and installation time. This translates to faster commissioning and lower labor costs on site. The unit delivers AC-3 operation up to 370 A at various voltages (including 415–690 V) while maintaining a 1000 V insulation rating, supporting efficient motor starting and reduced electrical stress on feeders and cables. With a 24 V control coil (50 Hz / 60 Hz), it aligns with common industrial control architectures, improving interoperability with existing PLC outputs and safety relays. The device features 27 W power loss per pole, contributing to manageable heat rise in enclosed panels and simpler thermal budgeting. Its IP40 protection and rugged bars-based main terminals simplify mounting and ensure reliable connectivity in harsh environments. Mechanical durability of 5 million cycles and a maximum switching rate of 300 cycles per hour offer longevity for high-frequency start-stop cycles, reducing maintenance cycles and extending machine uptime. The product’s compact footprint (140 mm W, 180 mm D, 225 mm H) and 4.7 kg weight support easy installation in control cabinets and machine frames, while its RoHS, REACH, and ISO-aligned certifications provide compliance assurance for global deployments.

Get a Quick Quote for a ABB 1SFL607074R8111

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SFL607074R8111?

Enquire Now

FAQs

The device features main circuit terminals designed as bars and a compact footprint suitable for standard control cabinets. With a 140 mm width, 180 mm depth, and 225 mm height, it fits typical industrial enclosures. Wiring should accommodate the 24 V control coil (50/60 Hz) and include the one NO auxiliary and one NC auxiliary contact for signaling. This layout simplifies panel wiring and reduces installation time, supporting quick integration with PLCs and motor protection relays.

For AC-3 duty, the contactor supports up to 370 A at voltages including 415, 440, 500, 690 V, with ratings adjusted for ambient temperature (55 °C) and voltage class. The main circuit is rated up to 1000 V insulation, and the unit provides a robust 8 x Ie breaking capacity and 10 x Ie making capacity for reliable motor starting and switching. This ensures safe operation for medium- to high-power motors in demanding applications.

Yes. The contactor is designed for high-current AC-3 applications with strong short-time withstand and durability specifications. Its 5 million mechanical cycles and 300 cycles per hour maximum switching frequency support frequent start-stop cycles typical in conveyors and pumps. The 24 V control coil aligns with standard PLC control, providing reliable operation even with surge-prone loads, while the 690 V mains rating accommodates a wide range of conveyor and pump drive systems.

The product carries CE declarations, UL certification, CCC conformity, RoHS compliance, and REACH declarations. These certifications indicate conformity with global electrical safety and environmental requirements, simplifying procurement for regulated facilities, enabling cross-border deployments, and reducing supplier risk. They support risk management, product liability considerations, and ensure compatibility with safety and environmental policies across multiple regions.

Maintenance benefits come from its high mechanical durability (5 million cycles) and robust insulation (690 V) with reliable 24 V control, reducing unexpected failures. The compact design saves panel space, while 27 W per pole minimizes heat load, lowering cooling energy costs. The device’s reliability translates to lower maintenance labor, reduced downtime, and improved uptime metrics, contributing to a favorable total cost of ownership in industrial automation projects.