ABB 1SFL657001R7000 Block Contactor - AF Technology

Part Number: 1SFL657001R7000

Quick Summary

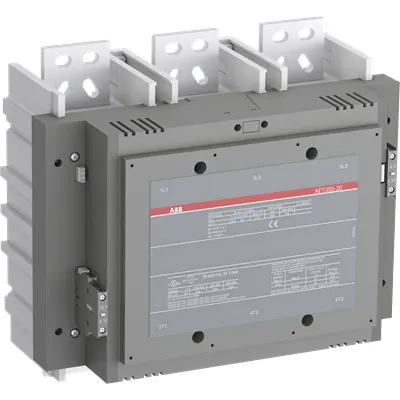

ABB 1SFL657001R7000 Block Contactor is a three-pole motor starter designed to switch motors up to 475 kW at 400 V AC in industrial drives. In real-world panels, fluctuating control voltages and limited space can reduce reliability and increase energy use. This AF technology delivers a wide control voltage range of 100–250 V (AC/DC), built-in surge protection, and broad certifications such as CE, UL/CSA, and UKCA to support global compliance. The compact block design pairs with add-on auxiliary contact blocks for scalable control, helping streamline installations and reduce downtime while supporting growing automation needs.

Product Information

Extended Description

1SFL657001R7000 ABB: The AF1350-30-00-70 is a 3 pole - 1000 V IEC or 1000 V UL contactor with Main Circuit Bars, controlling motors up to 475 kW / 400 V AC (AC-3) or 800 hp / 480 V UL and switching power circuits up to 1350 A (AC-1) or 1350 A UL general use. Thanks to the AF technology, the contactor has a wide control voltage range (100-250 V 50/60 Hz and DC), managing large control voltage variations, reducing panel energy consumptions and ensuring distinct operations in unstable networks. Furthermore, surge protection is built-in, offering a compact solution. AF contactors have a block type design, can be easily extended with add-on auxiliary contact blocks and an additional wide range of accessories.

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100214C0202 - Main catalog Motor protection and control Manual motor starters, contactors and overload relays (PDF) - Edition 2024

Data Sheet, Technical Information (Part 2)

Contactors and Overload relays guide

Instructions and Manuals

Operating instruction, Contactors AF1350, AF1650,AF2050

CAD Dimensional Drawing

Information - 2D and 3D files for CAD systems

Product Net Width

438 mm

Product Net Depth / Length

244 mm

Product Net Height

392 mm

Product Net Weight

32 kg

Number of Main Contacts NO

3

Number of Main Contacts NC

0

Number of Auxiliary Contacts NO

0

Number of Auxiliary Contacts NC

0

Number of Poles

3P

Rated Operational Voltage

Main Circuit 1000 V

Rated Operational Current AC-1 (Ie)

(1000 V) 40 °C 1350 A | (1000 V) 55 °C 1150 A | (1000 V) 70 °C 1000 A | (690 V) 40 °C 1350 A | (690 V) 55 °C 1150 A | (690 V) 70 °C 1000 A

Rated Operational Current AC-3 (Ie)

(220 / 230 / 240 V) 55 °C 860 A

Rated Operational Power AC-3 (Pe)

(415 V) 550 kW | (440 V) 560 kW | (500 V) 560 kW | (690 V) 800 kW | (1000 V) 560 kW | (380 / 400 V) 475 kW | (220 / 230 / 240 V) 257 kW

Rated Short-time Withstand Current Low Voltage (Icw)

at 40 °C Ambient Temp, in Free Air, from a Cold State 10 s 8000 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 15 min 1600 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 min 4500 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 s 10000 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 30 s 6000 A

Rated Insulation Voltage (Ui)

acc. to IEC 60947-4-1 and VDE 0110 (Gr. C) 1000 V | acc. to UL/CSA 1000 V

Rated Control Circuit Voltage (Uc)

50 Hz 100 ... 250 V

Coil Consumption

Holding at Max. Rated Control Circuit Voltage 50 Hz 48 V·A | Holding at Max. Rated Control Circuit Voltage 60 Hz 48 V·A | Pull-in at Max. Rated Control Circuit Voltage 50 Hz 2450 V·A | Pull-in at Max. Rated Control Circuit Voltage 60 Hz 2450 V·A | Pull-in at Max. Rated Control Circuit Voltage DC 2290 V·A

Power Loss

at Rated Operating Conditions per Pole 80 W

Terminal Type

Main Circuit: Bars

Product Name

Block Contactor

Maximum Operating Voltage UL/CSA

Main Circuit 1000 V

General Use Rating UL/CSA

(1000 V AC) 1350 A | (600 V AC) 1350 A

Horsepower Rating UL/CSA

(220 ... 240 V AC) Three Phase 400 Hp | (440 ... 480 V AC) Three Phase 800 Hp | (550 ... 600 V AC) Three Phase 1000 Hp

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

End Of Life Disassembling Instructions

End-of-life instruction - AF1350(B)(T), AF1650(B)(T), AF1650N8, AF2050(B)(T), AF2650(B)(T), AF2850(B)(T)

Environmental Product Declaration - EPD

Environmental product declaration AF1350(T), AF1650(T)(N), AF2050(T), AF2650(T), AF2850 (SE)

ABS Certificate

ABS Certificate, Contactor, AF400...AF2050 (Sweden)

BV Certificate

BV Certificate, Contactor, AF400 ... AF2850

CB Certificate

SEMKO_SE-74013

CCS Certificate

CCS Certificate, Contactor, AF116 to AF2850 (Sweden)

CQC Certificate

CQC Certificate, AC Contactor, AF1350-30-*-*, AF1650-30-*-*, AF2050-30-*-*, AF1350T-30-*-*, AF1650T-30-*-*, AF2050T-30-*-*, Made in Sweden | CQC Certificate, Contactor, AF1350, AF1650, AF2050, Made in China

Declaration of Conformity - CCC

CCC Declaration of Conformity, AC Contactor, AF1350-30-*-*, AF1650-30-*-*, AF2050-30-*-*, AF1350T-30-*-*, AF1650T-30-*-*, AF2050T-30-*-*, Made in Sweden | CCC Declaration of Conformity, Contactor, AF1350, AF1650, AF2050, Made in China

Declaration of Conformity - CE

CE Declaration of Conformity - Contactor - AF400...AF2850

Declaration of Conformity - UKCA

UK Declaration of Conformity - Contactors >100A

DNV GL Certificate

DNV Certificate, Contactor, AF400...AF2850

EAC Certificate

9AKK107046A8618

LR Certificate

Lloyds register Certificate, Contactor, AF400...AF2850

PRS Certificate

PRS Certificate - AF116...AF1650

RINA Certificate

RINA Certificate, AF95, AF110, AF145, AF185, AF210, AF260, AF300, AF400, AF460, AF580, AF750, AF1250, AF1350, AF1650, AF2050, AF2650, AF116, AF140, AF146, AF190, AF205, AF265, AF305, AF370

RMRS Certificate

9AKK107045A6978

UL Certificate

cULus Certificate, Contactor, AF1350, AF1650, AF2050 (NLDX)

UL Listing Card

UL_E73397

Package Level 1 Width

555 mm

Package Level 1 Depth / Length

365 mm

Package Level 1 Height

500 mm

Package Level 1 Gross Weight

34 kg

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4755 >> Contactors

AF technology enables a wide control voltage range (100–250 V AC/DC), reducing panel space and energy waste while ensuring reliable coil operation in networks with voltage variation. This translates to lower energy consumption, fewer control failures, and improved uptime in automated lines, conveyors, and pumps. The built-in surge protection minimizes nuisance trips and external snubbers, cutting component count and maintenance costs while simplifying panel design for motor protection and control applications. Main circuit bars and a three-pole configuration support up to 1350 A AC-1 and 860 A AC-3 at relevant voltages, enabling direct motor control for high‑power loads such as fans, compressors, and hoists with fewer devices. The AF contactor’s block-type design allows easy extension with add-on auxiliary contact blocks, enabling scalable control architectures without replacing the base unit, saving installation time and procurement costs. Coil consumption figures—holding at max rated control voltage: 48 V·A, pull-in at max rated voltage: 2450 V·A—provide predictable operating costs and heat management, contributing to more efficient panels and longer component life. Certifications and compliance coverage, including CE, UL/CSA, UKCA, and other global marks, reduce procurement risk and streamline supplier qualification for regulated industries such as energy, water, and manufacturing.

Get a Quick Quote for a ABB 1SFL657001R7000

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SFL657001R7000?

Enquire Now

FAQs

The AF1350-30-00-70 is a three-pole block contactor designed for panel mounting with a compact footprint and main circuit bars for easy wiring. It supports add-on auxiliary contact blocks to extend control capabilities without replacing the base unit, reducing downtime during upgrades and facilitating scalable automation in conveyors and pumps.

Rated operational current AC-1 is 1350 A at 1000 V or 690 V variants (with temperature adjustments: 40 °C 1350 A, 55 °C 1150 A, 70 °C 1000 A; at 690 V the values are similar). Rated AC-3 current at 55 °C is 860 A (for the 220–240 V class). These ratings guide motor sizing to ensure continuous operation without overheating under peak starting current and ambient conditions.

Yes. The AF1350-30-00-70 is designed for heavy motor control, supporting up to 475 kW at 400 V AC (AC-3) and 1350 A in AC-1 service. Its robust 1000 V insulation, wide coil voltage tolerance, and built-in surge protection make it well-suited for conveyors, pumps, fans, and other demanding automation applications in manufacturing and process environments.

This contactor carries CE, UL/CSA, UKCA, and multiple third-party certificates (CB, BV, LR, ABS, EAC, and others). Such certifications simplify cross‑regional sourcing, ensure regulatory compliance for industrial installations, and help satisfy procurement and safety audit requirements in multi-site operations.

Expect lower maintenance due to built-in surge protection and coil tolerance across voltage variations, reducing nuisance trips. The compact design and extendable auxiliary blocks shorten spare parts inventories and replacement times. The combination of high current capacity, energy-efficient coil operation, and fewer external components translates to a favorable total cost of ownership in high-volume motor control environments.