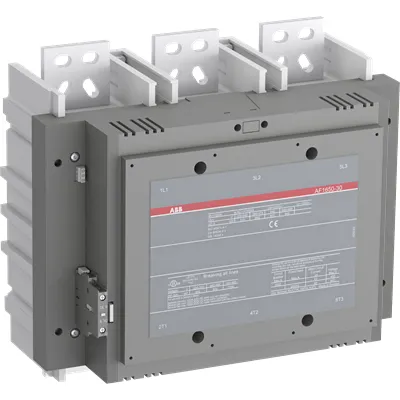

ABB AF1650-30-11 Block Contactor - UL/CSA & CE Certified

Part Number: 1SFL677033R7011

Quick Summary

ABB AF1650-30-11 Block Contactor provides reliable motor control for heavy-duty applications such as pumps, conveyors, and fans in industrial panels. In fast-changing electrical environments, voltage fluctuations can cause nuisance trips and increased maintenance, driving downtime and costs. This device carries CE and UL/CSA approvals, with UKCA and EAC certifications for global compliance, while coil terminals offer IP20 protection and main terminals IP00 for standard cabinet integration. Designed for easy procurement and installation, the AF1650 series supports pre-mounted auxiliary contacts and a wide control voltage range, delivering predictable operation and reduced panel complexity for electrical engineers and procurement specialists.

Product Information

Extended Description

1SFL677033R7011 ABB: The AF1650-30-11-70 CT19001 is a 3 pole - 1000 V IEC or 1000 V UL contactor pre-mounted auxiliary contacts and and Main Circuit Bars, controlling motors up to 560 kW / 400 V AC (AC-3) or 1150 hp / 480 V UL and switching power circuits up to 1650 A (AC-1) or 1650 A UL general use. Thanks to the AF technology, the contactor has a wide control voltage range (100-250 V 50/60 Hz and DC), managing large control voltage variations, reducing panel energy consumptions and ensuring distinct operations in unstable networks. Furthermore, surge protection is built-in, offering a compact solution. AF contactors have a block type design, can be easily extended with add-on auxiliary contact blocks and an additional wide range of accessories.

Minimum Order Quantity

1 piece

Customs Tariff Number

85364900

Data Sheet, Technical Information

1SBC100214C0202 - Main catalog Motor protection and control Manual motor starters, contactors and overload relays (PDF) - Edition 2024

Data Sheet, Technical Information (Part 2)

Contactors and Overload relays guide

Instructions and Manuals

Operating instruction, Contactors AF1350, AF1650,AF2050

CAD Dimensional Drawing

Information - 2D and 3D files for CAD systems

Dimension Diagram

Dimension Drawing, Contactor, AF1350, AF1650

Product Net Width

438 mm

Product Net Depth / Length

244 mm

Product Net Height

392 mm

Product Net Weight

33 kg

Number of Main Contacts NO

3

Number of Main Contacts NC

0

Number of Auxiliary Contacts NO

1

Number of Auxiliary Contacts NC

1

Number of Poles

3P

Rated Operational Voltage

Main Circuit 1140 V

Rated Frequency (f)

Main Circuit 50 / 60 Hz

Conventional Free-air Thermal Current (Ith)

acc. to IEC 60947-4-1, Open Contactors Θ = 40 °C 1650 A

Rated Operational Current AC-1 (Ie)

(1000 V) 40 °C 1650 A | (1000 V) 55 °C 1450 A | (1000 V) 70 °C 1270 A | (690 V) 40 °C 1650 A | (690 V) 55 °C 1450 A | (690 V) 70 °C 1270 A | (1140 V) 40 °C 1650 A

Rated Operational Current AC-3 (Ie)

(1000 V) 55 °C 400 A | (220 / 230 / 240 V) 55 °C 1060 A

Rated Operational Current DC-1 (Ie)

(220 V) 3 Poles in Series, 40 °C 1650 A | (600 V) 3 Poles in Series, 40 °C 1650 A | (850 V) 3 Poles in Series, 40 °C 1650 A

Rated Short-time Withstand Current Low Voltage (Icw)

at 40 °C Ambient Temp, in Free Air, from a Cold State 10 s 10000 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 15 min 2200 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 min 5500 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 1 s 12000 A | at 40 °C Ambient Temp, in Free Air, from a Cold State 30 s 7500 A

Maximum Breaking Capacity

cos phi=0.45 (cos phi=0.35 for Ie > 100 A) at 440 V 12000 A

Rated Insulation Voltage (Ui)

acc. to IEC 60947-4-1 and VDE 0110 (Gr. C) 1140 V | acc. to UL/CSA 1000 V

Rated Impulse Withstand Voltage (Uimp)

Main Circuit 8 kV

Maximum Electrical Switching Frequency

(AC-1) 60 cycles per hour

Mechanical Durability

0.5 million

Maximum Mechanical Switching Frequency

300 cycles per hour

Coil Operating Limits

(acc. to IEC 60947-4-1) 0.85 x Uc Min. ... 1.1 x Uc Max. (at θ ≤ 70 °C)

Rated Control Circuit Voltage (Uc)

50 Hz 100 ... 250 V | 60 Hz 100 ... 250 V | DC Operation 100 ... 250 V

Coil Consumption

Holding at Max. Rated Control Circuit Voltage 50 Hz 48 V·A | Holding at Max. Rated Control Circuit Voltage 60 Hz 48 V·A | Holding at Max. Rated Control Circuit Voltage DC 20.5 V·A | Pull-in at Max. Rated Control Circuit Voltage 50 Hz 2450 V·A | Pull-in at Max. Rated Control Circuit Voltage 60 Hz 2450 V·A | Pull-in at Max. Rated Control Circuit Voltage DC 2290 V·A

Power Loss

at Rated Operating Conditions per Pole 80 W

Operate Time

Between Coil De-energization and NC Contact Closing 35 ... 55 ms | Between Coil De-energization and NO Contact Opening 35 ... 55 ms | Between Coil Energization and NC Contact Opening 50 ... 80 ms | Between Coil Energization and NO Contact Closing 50 ... 80 ms

Connecting Capacity Main Circuit

Bar 100 mm²

Connecting Capacity Auxiliary Circuit

Flexible with Ferrule 2x 0.75 ... 2.5 mm² | Flexible with Insulated Ferrule 1x 0.75 ... 2.5 mm² | Flexible 2x0.75 ... 2.5 mm² | Solid 2 x 1 ... 4 mm² | Stranded 2 x 1 .... 4 mm²

Connecting Capacity

Bar 100 mm²

Degree of Protection

acc. to IEC 60529, IEC 60947-1, EN 60529 Coil Terminals IP20 | acc. to IEC 60529, IEC 60947-1, EN 60529 Main Terminals IP00

Tightening Torque

Cable Lug 45 N·m

Terminal Type

Main Circuit: Bars

Product Name

Block Contactor

NEMA Size

8

Horsepower Rating NEMA

(230 V AC) Three Phase 450 Hp | (460 V AC) Three Phase 900 Hp | (575 V AC) Three Phase 900 Hp

Maximum Operating Voltage UL/CSA

Main Circuit 1000 V

General Use Rating UL/CSA

(1000 V AC) 1650 A | (600 V AC) 1650 A

Ambient Air Temperature

Close to Contactor Fitted with Thermal O/L Relay (0.85 ... 1.1 Uc) -25 ... 50 °C | Close to Contactor without Thermal O/L Relay (0.85 ... 1.1 Uc) -40 ... 70 °C | Close to Contactor for Storage -40 ... 70 °C

Maximum Operating Altitude Permissible

Without Derating 3000 m

Conflict Minerals Reporting Template (CMRT)

CMRT - Conflict Minerals Reporting Template

REACH Declaration

REACH - Letter of Confirmation for block contactors, contactor relays, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Information

RoHS II declaration for block contactors, installation contactors, mini contactors, mini contactor relays, thermal overload relays, electronic overload relays and related accessories

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Toxic Substances Control Act - TSCA

Toxic Substances Control Act (TSCA) declaration for Contactors

WEEE B2C / B2B

Business To Business

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

End Of Life Disassembling Instructions

End-of-life instruction - AF1350(B)(T), AF1650(B)(T), AF1650N8, AF2050(B)(T), AF2650(B)(T), AF2850(B)(T)

Environmental Product Declaration - EPD

Environmental product declaration AF1350, AF1650, AF2050, AF2650 (CN) Contactors

CB Certificate

SEMKO_SE-74013

CCS Certificate

CCS Certificate, Contactor, AF116 to AF2850 (Sweden)

CQC Certificate

CQC Certificate, AC Contactor, AF1350-30-*-*, AF1650-30-*-*, AF2050-30-*-*, AF1350T-30-*-*, AF1650T-30-*-*, AF2050T-30-*-*, Made in Sweden | CQC Certificate, Contactor, AF1350, AF1650, AF2050, Made in China

Declaration of Conformity - CCC

CCC Declaration of Conformity, AC Contactor, AF1350-30-*-*, AF1650-30-*-*, AF2050-30-*-*, AF1350T-30-*-*, AF1650T-30-*-*, AF2050T-30-*-*, Made in Sweden | CCC Declaration of Conformity, Contactor, AF1350, AF1650, AF2050, Made in China

Declaration of Conformity - CE

CE Declaration of Conformity - Contactor - AF400...AF2850

Declaration of Conformity - UKCA

UK Declaration of Conformity - Contactors >100A

EAC Certificate

9AKK107046A8618

LR Certificate

Lloyds register Certificate, Contactor, AF400...AF2850

UL Certificate

cULus Certificate, Contactor, AF1350, AF1650, AF2050 (NLDX)

Package Level 1 Units

box 1 piece

Package Level 1 Width

555 mm

Package Level 1 Depth / Length

365 mm

Package Level 1 Height

500 mm

Package Level 1 Gross Weight

35 kg

Package Level 1 EAN

7320500524985

Package Level 2 Units

1 piece

Object Classification Code

Q

ETIM 7

EC000066 - Power contactor, AC switching

ETIM 8

EC000066 - Power contactor, AC switching

ETIM 9

EC000066 - Power contactor, AC switching

eClass

V11.0 : 27371003

UNSPSC

39121529

IDEA Granular Category Code (IGCC)

4755 >> Contactors

Feature → Business Impact → Application: The AF1650-30-11 operates over a wide control voltage range of 100-250 V (50/60 Hz) and DC, reducing panel energy consumption and increasing resilience to voltage variation in unstable networks. It translates into fewer panel redesigns and lower night-and-weekend maintenance costs for motor-driven systems such as pumps, fans, and conveyors. Application: use in electrical panels in water treatment, manufacturing lines, and packaging systems where supply voltage can vary. Feature → Business Impact → Application: With 3 main NO contacts and 1 NO + 1 NC auxiliary contact, the block design supports straightforward expansion via add-on auxiliary blocks, cutting integration time and enabling staged automation upgrades. Application: retrofit projects and scalable motor control in HVAC, material handling, and process lines. Feature → Business Impact → Application: High current ratings (AC-1 up to 1650 A, AC-3 up to 400 A at 1000 V) deliver robust performance for high-inertia loads, reducing fault currents and improving motor start reliability. Application: large drum crushers, centrifuges, and belt-driven conveyors. Feature → Business Impact → Application: Built-in surge protection and insulation up to 1140 V Ui minimize panel space and component count, improving compliance and safety while enabling compact, modular motor control. Application: compact plant floors and cabinet assemblies with limited space. Feature → Business Impact → Application: Mechanical durability of 0.5 million cycles and 80 W per pole power loss support long service life with predictable maintenance cycles. Application: steady operation in continuous-running equipment; reduces maintenance windows. Feature → Business Impact → Application: Wide connectivity options—100 mm² main circuit bars and flexible auxiliary conductor ranges (0.75–4 mm² ferrules/solid/stranded connections)—simplifies wiring, decreases installation time, and improves terminal reliability in harsh manufacturing environments. Application: energy-intensive fans, pumps, and hoists in food and beverage, chemical, and metalworking plants.

Get a Quick Quote for a ABB 1SFL677033R7011

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1SFL677033R7011?

Enquire Now

FAQs

AF1650-30-11 is a 3-pole block contactor with 100-250 V control voltage and 1140 V insulation. It uses main circuit bars with 100 mm² capacity and accepts flexible/wired auxiliary connections. Ensure proper IP20 coil terminals and IP00 main terminals are used, and verify derating guidelines for ambient temperatures up to 50 °C with thermal overload relays.

Key specs include 3 main NO contacts, 1 NO + 1 NC auxiliary, rated insulation voltage 1140 V, AC-1 Ie up to 1650 A at 40 °C, AC-3 Ie up to 400 A at 1000 V, coil voltage 100-250 V (50/60 Hz) or DC, and a coil consumption of 48 V·A holding with higher pull-in values. Short-time withstand and mechanical durability support reliable operation in demanding environments.

Suitable for large-motor control in conveyors, pumps, and HVAC systems within manufacturing, processing, and material handling applications. Its 3P configuration, high Ie, and wide control voltage range make it a solid choice for plants requiring reliable motor start/stop control, energy efficiency, and scalable expansion with auxiliary contact blocks.

The device carries CE and UL/CSA certifications, plus UKCA and EAC confirmations, among others like LR, CCC, and CQC. These certifications support global procurement and regulatory compliance. Always verify the latest certificates and local compliance requirements for the target installation region.

With a mechanical durability of about 0.5 million cycles and low power loss (80 W per pole), maintenance intervals can be extended while keeping energy use predictable. The wide control voltage range reduces panel wiring and spare part variety, improving total cost of ownership in high-demand motor control scenarios.