ABB 1STQ003508M0000 Touch protection for InLine enclosure - RoHS II

Part Number: 1STQ003508M0000

Quick Summary

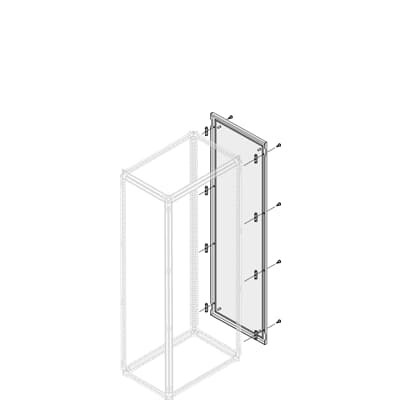

ABB 1STQ003508M0000 touch protection for InLine enclosures protects operators on 1000 mm wide panels. In busy automation lines, gaps and exposed edges invite finger injuries and hinder maintenance efficiency, especially during quick changeovers. This solution meets RoHS II requirements, REACH compliance with no substances exceeding 0.1 mass percentage, and WEEE category 5 disposal guidelines, helping you stay compliant across markets. The Lexan shield provides durable impact resistance while maintaining clear visibility, and its installation integrates smoothly into ABB InLine frames, reducing commissioning time. For procurement teams, it delivers predictable protection, regulatory assurance, and a clear path to safe, compliant operation across multiple projects.

Product Information

RoHS Information

LB-DT 19-21D - RoHS II - Enclosures

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

RoHS Date

20231024

REACH Information

False - does not contain substances > 0.1 mass percentage

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

ETIM 9

EC002525 - Divider panel (enclosure/cabinet)

Feature: Lexan touch protection shields operators while preserving visibility and touch response. Business Impact: Reduces the risk of finger injuries and incidental contact, lowering incident-related downtime and insurance exposure. Application: Fits ABB InLine enclosures with width 1000 mm, enabling safe access during routine maintenance and changeovers. Feature: RoHS II and REACH compliance ensures regulatory readiness. Business Impact: Mitigates non-compliance penalties and simplifies cross-border sourcing. Application: Ideal for European installations and multi-site deployments where strict material safety standards apply. Feature: WEEE Category 5 classification supports responsible end-of-life management. Business Impact: Streamlines disposal workflows and reduces environmental compliance risk. Application: Aligns with facility recycling programs and corporate sustainability targets. Feature: ETIM 9 EC002525 divider panel classification improves cataloging and procurement accuracy. Business Impact: Enhances ERP and e-procurement integration, reducing ordering errors. Application: Helps specify the correct enclosure accessory in maintenance and project briefs. Feature: Easy installation and ABB InLine compatibility cut commissioning time. Business Impact: Minimizes downtime during line upgrades and replacements, boosting uptime. Application: Plug-and-play alignment with existing mounting patterns on 1000 mm InLine systems.

Get a Quick Quote for a ABB 1STQ003508M0000

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1STQ003508M0000?

Enquire Now

FAQs

Installation is designed to be straightforward with the existing mounting points on 1000 mm InLine cabinets. Align the Lexan shield to the enclosure face, secure with standard fasteners, and verify clear visibility and finger protection. Ensure the edge protection remains intact during routine maintenance to maintain safety performance over time.

Yes. The product adheres to RoHS II (LB-DT 19-21D) for enclosures and is REACH compliant with no substances exceeding 0.1 mass percentage. This helps procurement meet EU regulatory requirements and supports responsible material choices across European operations.

The protective Lexan panel is designed for InLine enclosures with a width of 1000 mm. It aligns with ABB’s InLine frame systems to provide a seamless retrofit or new-install protection solution, while ETIM 9 classification ensures correct catalog placement.

WEEE Category 5 denotes small equipment with no external dimension over 50 cm. This categorization simplifies disposal and recycling planning at end-of-life, enabling safer and more compliant waste handling in industrial environments.

Expect reduced operator injury risk and lower maintenance downtime due to protected access. Regulatory compliance (RoHS II and REACH) lowers procurement risk, while straightforward installation accelerates commissioning. Over multiple line projects, this translates to safer operations and more predictable, repeatable safety outcomes.