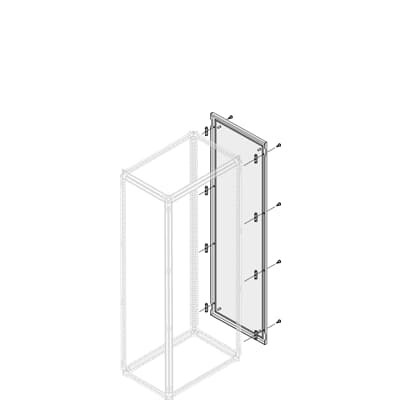

ABB 1STQ003515M0000 Lateral connection module - RoHS II Enclosures

Part Number: 1STQ003515M0000

Quick Summary

ABB 1STQ003515M0000 lateral connection module is designed to support power management enclosures in industrial cabinets. Many engineers face space limitations and wiring complexity when expanding enclosure layouts, which can delay projects and increase risk. It complies with RoHS II for enclosures, REACH information, and WEEE category 5, helping you meet regulatory expectations across regions. By aligning with ETIM EC002620 and installation standards, this module delivers dependable performance in distributed power systems while reducing lifecycle risk. In addition to core compliance, it offers compatibility with ABB enclosure families and scalable wiring options that enhance overall project efficiency and cost control.

Product Information

RoHS Information

LB-DT 19-21D - RoHS II - Enclosures

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

RoHS Date

20231024

REACH Information

False - does not contain substances > 0.1 mass percentage

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

ETIM 9

EC002620 - Components for installation (enclosure/cabinet)

Feature → Business Impact → Application: The module’s compact form factor (H=300mm, D=700mm) enables dense packing within power distribution enclosures, reducing cabinet footprint and simplifying wire routing for faster installations in automation cabinets. This translates to measurable space savings and shorter commissioning times on for-line systems, improving total cost of ownership as you deploy multiple panels across a plant. Feature → Regulatory compliance → Application: RoHS II, REACH information, and WEEE category 5 adherence minimize regulatory risk and disposal costs, supporting long-term maintenance planning and supplier continuity for critical automation assets. Feature → ETIM compatibility → Application: EC002620 classification confirms suitability for components used in installation, enclosure, and cabinet ecosystems, ensuring seamless BOM integration and cross-brand interoperability in mixed hardware environments. Feature → Material compliance → Application: Documentation of RoHS status and date (20231024) demonstrates traceable compliance, which simplifies customer audits and supplier qualification processes. Feature → Installation efficiency → Application: The module’s straightforward mounting within standard ABB enclosures reduces wiring errors and rework, delivering predictable lead times and improved site safety during live- installation campaigns.

Get a Quick Quote for a ABB 1STQ003515M0000

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1STQ003515M0000?

Enquire Now

FAQs

The 1STQ003515M0000 is designed for ABB power management enclosures with dimensions of 300 mm in height and 700 mm in depth. It aligns with ETIM EC002620 for installation components, ensuring compatibility across enclosure families and simplifying BOM planning, mounting, and wiring routes in industrial cabinets.

It complies with RoHS II (EU Directive 2011/65/EU and Amendment 2015/863), RoHS information LB-DT 19-21D, and provides REACH information indicating no substances above 0.1 mass percentage, along with WEEE category 5 classification for small equipment, supporting audit readiness and environmental compliance.

Yes. The module’s compact dimensions and ETIM EC002620 classification target installation components for enclosures and cabinets, enabling reliable wiring in tight spaces typical of compact distribution boards used in automated production lines.

Key certifications documented include RoHS II compliance for enclosures, RoHS status under EU Directive 2011/65/EU and Amendment 2015/863, RoHS date 20231024, REACH information, and WEEE category 5. ETIM 9 EC002620 further confirms installation compatibility within enclosure ecosystems.

The module reduces installation time and wiring complexity, improves regulatory compliance across facilities, and supports scalable deployment through EN enclosure compatibility. This translates to lower labor costs, fewer rework incidents, and a more predictable project timeline in large automation rollouts.