ABB 1STQ003709M0000 PCPA0004 Angular Plinth Covers - WEEE 4

Part Number: 1STQ003709M0000

Quick Summary

ABB 1STQ003709M0000 PCPA0004 angular plinth covers protect large enclosures in System pro E power installations. Maintenance teams often face gaps between footprint adapters and edge protection, leading to dust ingress and edge damage during upgrades. This plinth cover aligns with REACH information and WEEE categorization, supporting responsible material handling and end-of-life planning. While it does not contain substances above 0.1% mass, it contributes to safer, tidier installations and easier service access. Designed for B2B projects, it offers consistent fit and predictable inventory, reducing field errors. The 1 kg unit complements the System pro E power busbar ecosystem and aids efficient commissioning, with clear manuals and datasheet access for technicians.

Product Information

Extended Description

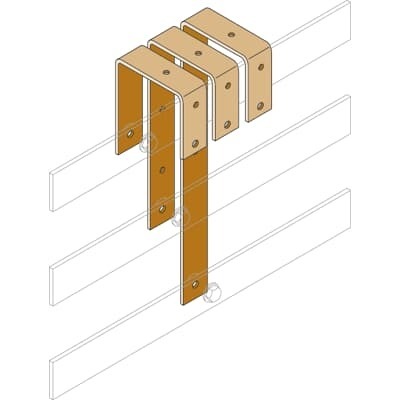

1STQ003709M0000 ABB: PCPA0004 n.4 angular plinth covers h=100

Software Category

A

REACH Information

False - does not contain substances > 0.1 mass percentage

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

WEEE B2C / B2B

Business To Business

Environmental Information

System pro E power - Empty enclosures and 185 mm Busbar System Technical Catalogue | Breakers - Packaging disposal information

Product Net Weight

1 kg

Package Level 1 Units

packet 1 piece

Instructions and Manuals

Instruction Handbook - System pro E power - RBBS/185 mm Busbar System - Plinth

Data Sheet, Technical Information

System pro E power - Empty enclosures and 185 mm Busbar System Technical Catalogue

Feature: N.4 angular plinth covers with a height of 100 mm provide a clean, protective edge to System pro E power enclosures. Business Impact: Reduces edge damage and dust ingress, lowering maintenance downtime and service calls. Application: Ideal for retrofit projects in factory automation lines that use System pro E power. | Feature: Compatibility with System pro E power and 185 mm busbar systems (RBBS/185 mm Busbar System - Plinth). Impact: Streamlines installation, reduces part counts, and ensures consistent aesthetics. Application: New builds and upgrades in electrical distribution for aggressive industrial environments. | Feature: Material compliance data shows REACH information and WEEE 4 classification; B2B. Impact: Supports regulatory compliance, safer procurement, and end-of-life planning. Application: Large equipment in industrial installations. | Feature: Documentation includes Instruction Handbook and System pro E power data catalogue. Impact: Reduces commissioning risk and accelerates technician training. Application: Field service and commissioning tasks. | Feature: 1 kg weight; packaging level packet 1 piece. Impact: Lightweight components ease handling, shipping, and stock management. Application: Stocking and quick re-order for enclosures.

Get a Quick Quote for a ABB 1STQ003709M0000

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 1STQ003709M0000?

Enquire Now

FAQs

Begin with a de-energized enclosure and confirm the PCPA0004 N.4 angular plinth covers (H=100). Refer to the Instruction Handbook for RBBS/185 mm Busbar System - Plinth, align the cover to enclosure edges, secure with suitable fasteners, and verify clearances and service access before re-energizing.

Yes. The plinth cover is designed for System pro E power enclosures and is compatible with the 185 mm busbar system RBBS/185 mm Busbar System - Plinth, helping to reduce extra adapters and ensure a consistent finish across installations.

The unit weighs 1 kg and is packed as a packet containing 1 piece. This packaging supports straightforward inventory management and efficient on-site handling during stocking and re-order processes.

Material compliance indicates REACH information with no substances above 0.1% mass and a WEEE Category 4 classification for Large Equipment, with Business To Business (B2B) applicability, simplifying regulatory and end-of-life planning for industrial buyers.

By protecting enclosure edges, reducing dust ingress, and streamlining installation, downtime is lowered and service costs decrease. The consistent fit and clear documentation also shorten commissioning times and improve lifecycle costs for System pro E power deployments.