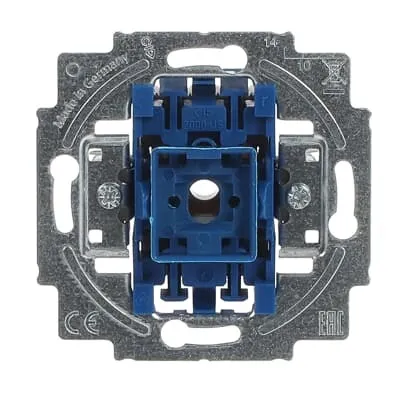

ABB 2CKA001012A1093 Switch Insert - IP20 IP Rated

Part Number: 2CKA001012A1093

Quick Summary

ABB 2CKA001012A1093 Switch Insert provides reliable intermediate switching for control panels and machines. Engineers often grapple with wiring complexity, limited space, and the challenge of keeping indicators visible under load. This module supports CE conformity and RoHS/REACH compliance, while IP20 protection offers dependable performance in typical indoor environments. Its flush-mounted design and mounting-plate kit simplify installation in legacy panels and retrofit projects, reducing field wiring time. With optional illumination and screwless terminals, you gain clearer status signals and safer, faster maintenance, boosting overall line efficiency.

Product Information

Extended Description

2CKA001012A1093 ABB: Can be illuminated by using a Illumination set as an accessory.

The Illumination set is powered by the connected load.

Suitability and maximum current for Illumination sets by the connected load must be ensured.

Mounting Type

Flush Mounted

Type of Fastening

Mounting with Claw | Mounting with Screw

Modular Components Included

Flush Mounted Insert with Mounting Plate

Degree of Protection

IP20

Function

Function lighting: Orientation

Number of Rocker Switches

1

Wiring Configuration

Intermediate switch

Actuator Type

Rocker/button

Illumination

Optional

Terminal Type

Screwless Terminals

Rated Voltage (Ur)

250 V

Rated Current (In)

10 A

Power Watt

LEDi / CFLi 100 W

Design Range

Platform 63 | Busch-Duro 2000 SI | Reflex SI | Busch-balance SI | Busch-art linear | future linear | Busch-axcent | solo | Pure Stainless Steel | carat | Busch-Dynasty | Allwetter 44 (IP 44) | alpha

Design Range Variant

Busch-Duro 2000 SI | Busch-Duro 2000 SI Linear | Reflex SI | Reflex SI Linear | Busch-art linear | Busch-art linear - with Decor Ring | Busch-art linear - pur | future | future linear | Busch-axcent | Busch-axcent pur | alpha nea | alpha exclusive

Surface Finishing

Untreated | Matt

Material

Thermoplastic | Duroplast

Product Net Width

71 mm

Product Net Height

71 mm

Product Net Depth / Length

40 mm

Product Net Weight

60 g

Built-In Depth (t2)

25 mm

Dimension Diagram

Dimension drawing [EN] m_2020usgl

RoHS Information

Product Declaration.PDF [EN] 2000/7 US

RoHS Status

Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

REACH Declaration

All Articles_REACH_EN_24-2_2CKA309999E9999

REACH Information

False - does not contain substances > 0.1 mass percentage

REACH Date

20250218

Conflict Minerals Reporting Template (CMRT)

Conflict Minerals Reporting Template

WEEE Category

5. Small Equipment (No External Dimension More Than 50 cm)

WEEE B2C / B2B

Business To Consumer

Declaration of Conformity - CE

EU-Declaration of conformity (.PDF) [EN] 2000/7 US

ETIM 9

EC001590 - Installation switch

eClass

V11.0 : 27144053

Flush-mounted installation minimizes panel intrusion, saving space and enabling seamless integration with existing housings; this reduces panel depth requirements and speeds wiring, delivering faster commissioning in automation racks. The 1 Rocker switch with an intermediate wiring configuration enables precise control sequencing, improving process reliability and reducing downtime during machine toning and start-up sequences. Illumination is optional, powered by the connected load, providing live status indication without extra drivers, which lowers total system cost and simplifies panel routing in busy control rooms. Screwless terminals improve connection reliability and speed maintenance while reducing terminal creep over time, supporting safer, longer service intervals. Rated for 250 V and 10 A with a 100 W capability, it handles common automation loads with headroom for LED and CFL indicators, reducing the need for additional modules. Compliance with IP20, CE, RoHS, and REACH streamlines regulatory onboarding and ensures cross-border readiness for European projects. The mounting options (claw or screw) and included mounting plate enable quick retrofits across Busch-Duro and Reflex style panels, delivering tangible installation efficiency and lower total cost of ownership.

Get a Quick Quote for a ABB 2CKA001012A1093

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 2CKA001012A1093?

Enquire Now

FAQs

The unit is designed for flush-mounted installation with either claw or screw mounting, and it comes with a mounting plate for fast retrofit. Begin by disconnecting power, remove the existing insert, align with the mounting plate, and secure using your preferred method. Terminals are screwless for quick connections, and the device supports standard 250 V, 10 A loads. For illumination, install the optional Illumination set powered by the connected load, ensuring your circuit can safely drive the indicator without overloading.

Key specs are 250 V rated voltage and 10 A rated current, suitable for medium-power control circuits. It supports an illumination option and has a 100 W maximum load for lighting within the circuit. The switch uses screwless terminals for reliable connections and is IP20 protected for typical indoor environments, which helps prevent dust intrusion in panel installations.

Yes, illumination is optional and is powered by the connected load. This means status indication can be added without a separate supply, simplifying wiring. When the illumination set is used, ensure the connected load can safely power the indicator and that the overall load does not exceed the 100 W capability.

The product supports CE conformity and RoHS/REACH compliance, with a Declaration of Conformity available. It carries IP20 protection and is listed for WEEE handling. These certifications help you meet EU regulatory requirements and environmental standards while ensuring safe operation in indoor industrial environments.

Benefits include faster installation due to flush-mounted design and screwless terminations, reduced wiring time with available mounting plate, and clearer status indication through optional illumination. These factors translate to lower labor costs, shorter downtime during panel upgrades, and improved process visibility, contributing to faster deployment, easier maintenance, and a lower total cost of ownership over the life of the automation line.