ABB 3GBA161430-ADPCN 3-Phase squirrel cage motor - IP55

Part Number: 3GBA161430-ADPCN

Quick Summary

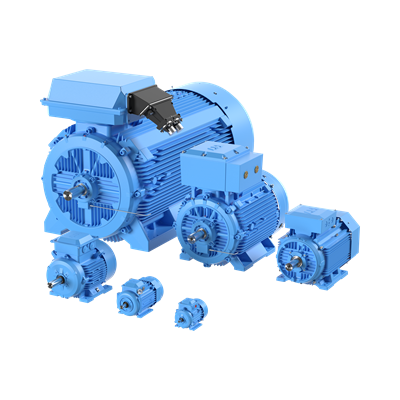

ABB 3GBA161430-ADPCN is a 3-phase squirrel cage motor built for continuous operation in tough industrial settings. Engineers often struggle with energy waste and downtime in demanding production lines. This motor delivers IP55 protection, IE4 efficiency, and IC411 insulation for rugged environments. Designed for easy integration with existing equipment, it helps lower operating costs and extend service intervals. By aligning with 160 frame assemblies and common VFDs, it minimizes downtime during retrofits and upgrades. Additionally, its continuous S1 duty and 40 °C ambient tolerance support reliable operation in modern manufacturing. With IP55 and IE4 in combination with robust cast iron frames, maintenance cycles are predictably longer and spare parts usage reduces. These characteristics support compliance and energy targets across plants, while simplifying procurement through a single, reliable motor family.

Product Information

ABB Type Designation

M2BAF 160MLC 2

Invoice Description

M2BAF 160MLC 2

Product Name

3-Phase squirrel cage motor

Product Type

CBF4__M2BAF_IE4_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 93.7 % | Partial Load (75%) 94.3 % | Partial Load (50%) 94.3 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

Frame Material

Cast Iron

Frame Size

160

Bearing

6309-2Z/C3

Bearing NDE

6209-2Z/C3

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

162 kg

Gross Weight

172 kg

UNSPSC

26101100

IE4 efficiency is baked into the motor design, delivering measurable energy savings in continuous operation across pumps, fans, and conveyors that dominate many manufacturing lines. Lower energy consumption translates directly into reduced annual energy costs, improved uptime, and better overall equipment effectiveness in facilities with high duty cycles and variable loads. In practice, pairing this motor with widely deployed variable frequency drives maintains necessary torque and speed while trimming peak electrical demand, enabling easier compliance with stringent corporate energy targets. IP55 protection keeps dust and moisture at bay, supporting reliable performance in dusty workshops, damp environments, washdown zones, and outdoor installations where harsher conditions are routine. That resilience reduces unplanned downtime, extends bearing life, and lowers maintenance costs for critical lines in packaging, automotive assembly, and material handling where reliability matters most. Seal design and enclosure allow straightforward installation without auxiliary protective housings, simplifying retrofits, reducing installation time, and decreasing total cost of ownership. The cast iron frame size 160 delivers stiffness, torsional resilience, and durability, allowing precise alignment with gearboxes and couplings that dominate heavy-duty lines. A robust bearing set, including 6309-2Z/C3 and 6209-2Z/C3 options, supports longer service intervals, smoother starts under load, and reduced vibration across a wide load range. The IMB3 IM1001 mechanical rating and D-End top terminator box location streamline installation, wiring, and maintenance while reducing cabling complexity and failure modes. Operational tolerance for environments up to 40 °C and up to 1000 meters altitude ensures consistent performance across diverse plants, climatic zones, and seasonal loading. Voltage Code D and a 2-pole, single-speed design provide straightforward electrical integration with existing distributions, MCCs, and control cabinets in many industries. Continuous S1 duty supports uninterrupted operation for conveyors, pumps, and processing lines, minimizing thermal cycling, extending motor life, and supporting predictable maintenance planning.

Get a Quick Quote for a ABB 3GBA161430-ADPCN

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA161430-ADPCN?

Enquire Now

FAQs

Yes. The 160 frame size aligns with common gearbox interfaces used in heavy-duty lines. The cast iron frame, paired bearings (6309-2Z/C3 or 6209-2Z/C3) and D-End top terminator box location simplify mounting, wiring, and field retrofit work. When upgrading, verify shaft alignment and ensure the mounting pattern matches your gearbox to avoid downtime.

IE4 efficiency indicates high energy performance under full-load conditions, translating to lower operating costs over the motor’s life. IP55 protection means protection against dust ingress and water jets, improving reliability in harsh environments. Together, they reduce energy consumption, downtime, and maintenance needs for demanding applications like conveyors and pumps.

Yes. The motor is rated for S1 duty and ambient temperatures up to 40 °C, making it appropriate for continuous duty on conveyors and similar load profiles. Its design also accommodates up to 1000 m altitude, ensuring stable performance across multiple plant locations.

Key ratings include IP55 protection and IE4 efficiency, along with IC411 insulation and ICbased classes. These specifications support reliable operation in challenging environments while helping meet energy efficiency targets and industry-specific compliance requirements in manufacturing and process facilities.

Expect longer service intervals, reduced spare-part consumption, and lower energy costs due to IE4 efficiency. The durable cast iron frame and robust bearings reduce wear, supporting predictable maintenance planning and faster ROI on retrofits or new line deployments.