ABB 3GBA183410-ADPCN 3-Phase Squirrel Cage Motor - IE4 IP55

Part Number: 3GBA183410-ADPCN

Quick Summary

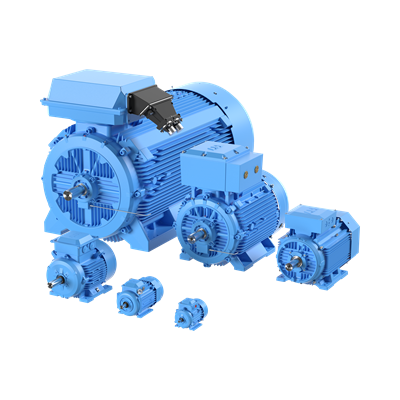

ABB 3GBA183410-ADPCN is a 3-phase squirrel cage motor designed for reliable, efficient operation in heavy industry applications such as conveyors and pumps. Engineers often confront rising energy costs and unplanned downtime when motors underperform or fail in harsh environments. This design delivers IE4 efficiency, IP55 protection, and ICLF insulation, enabling long service life and resilience in temperatures up to 40 °C and altitudes up to 1000 m. By aligning with standard ABB drives and automation components, it supports easy integration, predictable maintenance, and lower total cost of ownership. This combination of robustness and efficiency makes it a smart choice for automation-forward facilities seeking uptime, compliance, and cost savings.

Product Information

ABB Type Designation

M2BAF 180MLA 6

Invoice Description

M2BAF 180MLA 6

Product Name

3-Phase squirrel cage motor

Product Type

CBF4__M2BAF_IE4_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 92.9 % | Partial Load (75%) 93.2 % | Partial Load (50%) 92.7 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

Frame Material

Cast Iron

Frame Size

180

Bearing

6310-2Z/C3

Bearing NDE

6210-2Z/C3

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

211 kg

Gross Weight

221 kg

UNSPSC

26101100

Energy efficiency drives cost savings and reliability. Feature → Business Impact → Application: The motor meets IE4 class efficiency with full-load 92.9% efficiency and partial-load performance around 93%, reducing energy consumption in continuous duty applications such as conveyors and pumps. This translates to lower operating costs and improved sustainability across plant floors. The application is optimized for S1 duty in demanding environments, delivering predictable performance and reduced thermal stress during peak load cycles.Protection and durability are enhanced by IP55 and a cast iron frame. Feature → Business Impact → Application: IP55 sealing guards against dust and moisture, while a robust 180 mm cast-iron frame supports vibration resistance and rugged operation in washdown areas and outdoor installations. This combination minimizes maintenance downtime and extends mean time between failures in material handling and processing lines.Robust mechanical construction supports long life. Feature → Business Impact → Application: The 6-pole design, bearing configuration (6310-2Z/C3), and IMB3 IM1001 mounting class enable stable, low-vibration operation at multiple loads. In practice, this reduces bearing wear and maintenance costs for packaging systems and fans in automated plants.Installation and retrofit flexibility. Feature → Business Impact → Application: Direction of rotation on both ends and a D-End top termination box simplify wiring and retrofits in existing lines, cutting installation time and avoiding costly rework when upgrading legacy equipment in production lines. This is especially valuable for OEMs integrating new drives with existing conveyors and machine tools.Environmental and regulatory readiness. Feature → Business Impact → Application: Altitude up to 1000 m and ambient temperature up to 40 °C ensure reliable operation in varied plant locations, while the insulation class ICLF supports steady performance under hotter and dustier conditions common in metalworking and process industries. These traits help facilities maintain compliance while boosting uptime.

Get a Quick Quote for a ABB 3GBA183410-ADPCN

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA183410-ADPCN?

Enquire Now

FAQs

This motor is designed for seamless integration with common ABB drive solutions and three-phase electrical systems. It uses a voltage code of D and supports S1 continuous duty, making it straightforward to pair with ABB variable frequency drives for precise speed control and energy optimization in conveyors, pumps, and fans.

The motor meets IE4 efficiency with full-load efficiency around 92.9% and partial-load values near 93.2% at 75% load and 92.7% at 50% load. It is rated for S1 duty, ensuring reliable continuous operation in demanding applications such as material handling and processing lines.

Yes. The unit is specified for ambient temperatures up to 40 °C and altitude up to 1000 m, making it suitable for many plant floors and outdoor installations where environmental conditions are challenging yet within the motor’s design envelope.

Key features include a cast iron frame (180), bearing set 6310-2Z/C3, IMB3 IM1001 mounting class, and a D-End top termination box. Direction of rotation on both ends provides installation flexibility, and the 180 frame size supports robust mounting in heavy equipment such as conveyors and pumps.

Common applications include conveyors, pumps, and fans in automation systems. The motor’s IE4 efficiency and IP55 protection reduce energy use and maintenance needs, while the robust construction and flexible mounting simplify retrofit projects, delivering lower total cost of ownership and improved uptime for manufacturing and processing facilities.