ABB 3GBA201410-BDPCN 3-Phase Squirrel Cage Motor - IP55 IE4

Part Number: 3GBA201410-BDPCN

Quick Summary

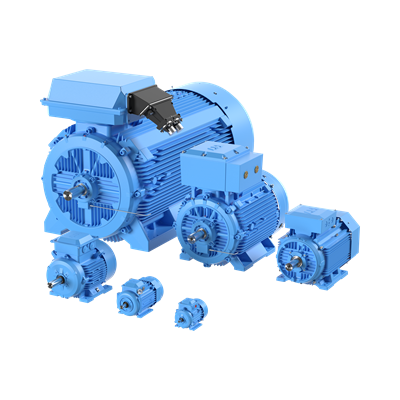

ABB 3GBA201410-BDPCN is a 3-phase squirrel cage motor designed for demanding industrial drives such as conveyors, pumps, and machine tools. When downtime or energy waste erodes productivity, a reliable motor with predictable performance becomes a competitive asset. This design delivers IP55 protection, IE4 efficiency, and robust insulation (IC411/ICLF) with a durable cast-iron frame for long life in tough environments. For procurement teams, a standard 200 frame, 1 piece minimum, and clear country-of-origin simplify sourcing, installation, and total cost of ownership. This motor's 2-pole design and S1 duty make it a dependable solution for continuous operation in challenging environments. Its standard packaging and compatibility with common starter equipment support fast deployment and predictable maintenance.

Product Information

ABB Type Designation

M2BAF 200MLA 2

Invoice Description

M2BAF 200MLA 2

Product Name

3-Phase squirrel cage motor

Product Type

CBF4__M2BAF_IE4_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 94.5 % | Partial Load (75%) 95.1 % | Partial Load (50%) 94.9 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

Frame Material

Cast Iron

Frame Size

200

Bearing

6312-2Z/C3

Bearing NDE

6212-2Z/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

263 kg

Gross Weight

273 kg

UNSPSC

26101100

Feature: IE4 energy efficiency is achieved through optimized winding design and low-loss materials, delivering sustained savings on running costs. Business Impact: Reduces operating expenses over the motor’s life cycle and improves ROI in high-usage lines. Application: Ideal for conveyors, pumps, and fans in continuous-duty applications where energy efficiency is a priority. Feature: IP55 protection with a cast-iron frame provides rugged durability and protection from dust and water jets. Business Impact: Lower maintenance frequencies and fewer unscheduled downtime events in harsh environments. Application: Suitable for outdoor, wash-down, and dusty plants such as steel, mining, and chemical processing. Feature: Cast Iron frame size 200 with bearing 6312-2Z/C3 delivers robust mechanical integrity. Business Impact: Longer bearing life and reduced friction-related wear, lowering replacement costs. Application: Heavy-duty manufacturing, pressing, and material handling. Feature: Direction of Rotation is available on both sides, enabling flexible installation. Business Impact: Reduces wiring permutations and installation time, improving project timelines. Application: Reversible conveyors, mixers, and packaging lines. Feature: Altitude and ambient tolerance—up to 1000 m and 40 °C—support operation in elevated facilities. Business Impact: Maintains performance without derating in typical high-altitude plants. Application: Mountain-region plants, elevated production floors, and remote facilities. Feature: Duty and construction—S1 continuous duty, 2-pole design, 200 frame, and IMB5 IM3001 alignment. Business Impact: Smooth, uninterrupted operation with predictable torque and startup behavior; lower maintenance demands. Application: Pumps, fans, grinders, and processing equipment in continuous service.

Get a Quick Quote for a ABB 3GBA201410-BDPCN

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA201410-BDPCN?

Enquire Now

FAQs

When pairing the ABB 3GBA201410-BDPCN with a VFD or soft starter, ensure voltage code D compatibility and proper current control settings. The motor features a standard 200 frame with a D-End top terminator box location, which simplifies wiring and enclosure layout. Verify bearing clearances and secure mounting, and use appropriate fan cooling if running near maximum load for extended periods. The result is smoother starts, reduced inrush, and longer motor life.

IE4 efficiency reflects significantly lower losses during operation, translating to meaningful energy savings in continuous-duty roles such as conveyors and pumps. In 50 Hz service, the data indicates high-load efficiency around 94.5% and very favorable partial-load performance, which reduces running costs, lowers heat generation, and can shorten payback periods when upgrading from lower-efficiency motors.

Yes. The motor carries IP55 protection, meaning it is well-sealed against dust ingress and water jets from any direction. Coupled with a robust cast-iron frame and ICFL insulation, this makes the motor suitable for harsh industrial settings, including dusty production floors and wash-down zones, where reliability and uptime are critical.

Key operating conditions include an ambient temperature rating of 40 °C and altitude up to 1000 m. The motor uses a 2-pole, S1 continuous duty design with ICClass insulation (ICLF) and IC411 class. Compliance highlights also include IP55 protection and an ABB model designation M2BAF 200MLA 2, with origin China (CN) and tariff code 85015230, supporting regulatory and import considerations.

Upgrading to this IE4-compliant motor typically yields energy cost reductions in continuous-duty operations due to lower losses, while the robust build reduces maintenance and downtime. The combination of high protection IP55, durable cast-iron frame, and reliable bearings contributes to predictable maintenance planning and longer service life, which translates to faster payback and lower total cost of ownership over the motor’s lifetime.