ABB 3GBA201420-ADPCN 3-Phase Squirrel Cage Motor - IP55

Part Number: 3GBA201420-ADPCN

Quick Summary

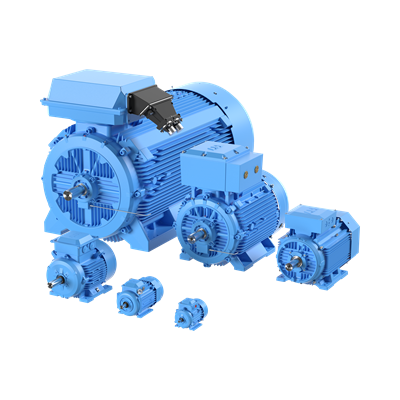

ABB 3GBA201420-ADPCN is a 3-phase squirrel cage motor designed for robust industrial drives in process and packaging lines. Engineers often struggle with reliability and energy costs in high-duty applications. Key certifications and standards supporting performance include IP55 enclosure, IE4 efficiency, and IC411 insulation, ensuring long life in dusty or hot environments. By aligning with ABB's rugged 200 frame, this motor minimizes maintenance and improves uptime, while compatibility with standard drives helps streamline procurement. Used in conveyors, pumps, and fans across manufacturing, its robust design lowers total cost of ownership.

Product Information

ABB Type Designation

M2BAF 200MLB 2

Invoice Description

M2BAF 200MLB 2

Product Name

3-Phase squirrel cage motor

Product Type

CBF4__M2BAF_IE4_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 94.8 % | Partial Load (75%) 95.2 % | Partial Load (50%) 95.2 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

Frame Material

Cast Iron

Frame Size

200

Bearing

6312-2Z/C3

Bearing NDE

6212-2Z/C3

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

268 kg

Gross Weight

278 kg

UNSPSC

26101100

The motor delivers high efficiency IE4 performance, which translates into tangible energy savings and lower operating costs for continuous-duty lines. This efficiency, combined with a cast iron frame and IP55 protection, reduces downtime due to environmental exposure and supports reliable operation in harsh factory floors. The insulation class ICLF and ambient temperature rating of 40 °C enable stable performance in elevated heat, while altitude up to 1000 m minimizes derating concerns in many plants. With a 200 mm frame and a two-pole design, installation meets common industry standards and enables straightforward drive integration for process automation. The robust bearing setup (6312-2Z/C3) and IMB3 IM1001 class ensure long service life and predictable lubrication cycles, lowering maintenance cost and extending the interval between repairs. The D-End top terminator box location simplifies wiring and reduces installation time, delivering a practical, reliable solution for conveyors, pumps, and fans in demanding environments. Overall, this motor aligns with industrial automation needs by combining rugged construction, precise performance, and easy procurement while supporting long-term total cost of ownership reductions.

Get a Quick Quote for a ABB 3GBA201420-ADPCN

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA201420-ADPCN?

Enquire Now

FAQs

This motor uses a 200 frame and IMB3 IM1001 mounting class, with a D-End top terminator box, making it compatible with most standard VFDs and drive packages used in industrial automation. The 2-pole design supports common 50/60 Hz supplies, while the robust cast iron frame ensures stable mounting on standard base plates and couplings. Plan wiring around the top box access for efficient installation.

The motor complies with IE4 efficiency, delivering Full Load efficiency around 94.8% and high partial-load efficiencies (75% and 50%) around 95.2%, which reduces energy costs on long-running applications. With IP55 protection, IC ICF insulation, and a continuous S1 duty, it is built for reliable operation in normal factory ambient conditions, minimizing unexpected downtime in process lines.

Yes. The motor’s 200 frame, cast iron construction, and IC411 insulation support reliable operation in demanding environments. Its IP55 enclosure protects against dust and water jets, while the IE4 efficiency reduces running costs for pumps, fans, and conveyors. The two-pole design provides suitable speed ranges for typical process equipment employed in packaging and manufacturing lines.

Key standards include IP55 protection for hostile environments, IE4 efficiency for energy compliance, and IC411 insulation class for safe operation at higher ambient temperatures. The motor’s origin and tariff classification are China (CN) with a tariff number of 85015230, supporting import documentation and compliance in many regions.

With 6312-2Z/C3 bearings and a durable cast iron frame, maintenance intervals are extended and bearing life is predictable, reducing unplanned downtime. The D-End top terminator box speeds wiring and service access, aiding quick inspections. Energy savings from IE4 efficiency, combined with reliable uptime, contribute to a favorable total cost of ownership for continuous-use applications like conveyors and pumps.