ABB 3GBA221210-BDPCN 3-Phase Squirrel Cage Motor - IE4 IP55

Part Number: 3GBA221210-BDPCN

Quick Summary

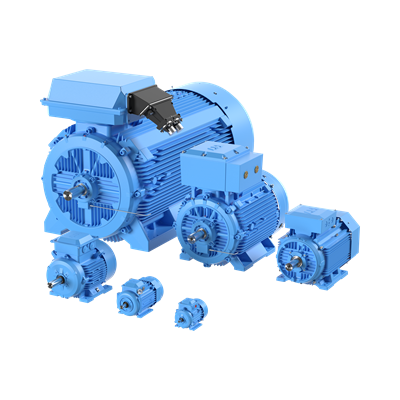

ABB 3GBA221210-BDPCN 3-Phase Squirrel Cage Motor delivers reliable torque for heavy industry applications. Maintenance downtime and energy waste are common pain points in plant rooms, and this motor helps address both. Key certifications include IE4 efficiency, IP55 enclosure, and IC411 insulation class, enabling compliant operation in dusty, warm environments. For OEMs and maintenance teams, rugged cast-iron construction and continuous-duty capability translate into measurable lifecycle savings. Its compatibility with standard motor starters and common drive systems reduces installation risk and shortens commissioning time. This combination supports energy-conscious plant modernization without sacrificing reliability.

Product Information

ABB Type Designation

M2BAF 225SMA 2

Invoice Description

M2BAF 225SMA 2

Product Name

3-Phase squirrel cage motor

Product Type

CBF4__M2BAF_IE4_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015290

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 95.0 % | Partial Load (75%) 95.2 % | Partial Load (50%) 94.7 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

Frame Material

Cast Iron

Frame Size

225

Bearing

6313-2Z/C3

Bearing NDE

6213-2Z/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

347 kg

Gross Weight

357 kg

UNSPSC

26101100

IE4 efficiency reduces energy consumption in continuous duty lines, lowering operating costs and heat generation. This helps plants meet energy targets and reduces cooling loads in automated lines. Applications include pumps, fans, conveyors in manufacturing and processing facilities. IP55 protection guards against dust ingress and water spray, extending service intervals in harsh factory floors and outdoor installations. Cast iron frame and a robust 225 frame provide rigidity and vibration damping, improving bearing life and reducing shaft stress in demanding handling and material-transport setups. The 6313-2Z/C3 bearings with NDE 6213-2Z/C3 deliver low-maintenance performance, while IMB5 IM3001 mounting supports straightforward installation in existing bases. Duty is S1 with 40 °C ambient temperature and up to 1000 m altitude, ensuring reliable operation in continuous processing lines.

Get a Quick Quote for a ABB 3GBA221210-BDPCN

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA221210-BDPCN?

Enquire Now

FAQs

Yes. The 3GBA221210-BDPCN is designed for standard three-phase supply and integrates with widely used variable frequency drives and control panels. With voltage code D and an IP55 enclosure, it supports typical industrial automation configurations while maintaining reliable start-up and smooth speed control in continuous operation.

This motor is rated IE4 for high efficiency, which reduces electrical losses during operation. In continuous-duty applications, IE4 can significantly lower energy bills and reduce cooling requirements. The improved efficiency translates to lower total cost of ownership, especially in pumps, fans, and conveyors where duty cycles are long and frequent starts are common.

Yes. The motor features IP55 protection and IC411 insulation, enabling operation in dusty and warm industrial spaces. With an ambient temperature rating of 40 °C and a 1000 m altitude consideration, it maintains performance and reliability for long, uninterrupted cycles typical of S1 duty in processing lines and material handling.

Key maintenance advantages include a cast-iron frame for durability, a 2-pole design for robust torque, and bearing arrangements of 6313-2Z/C3 with NDE 6213-2Z/C3 for enhanced life and easy replacement. The IMB5 IM3001 mounting class supports straightforward installation, minimizing alignment issues and downtime during service or upgrades.

The motor uses a 225 frame with a cast-iron construction, net weight around 347 kg and gross weight about 357 kg, suitable for fixed installations with rigid bases. It is manufactured in China (CN), with a Customs Tariff Number of 85015290, and features a D-end top termination box to simplify electrical connections during setup and maintenance.