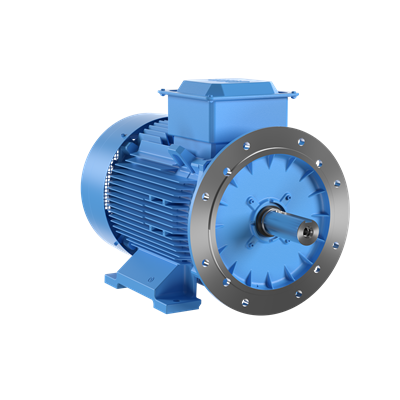

ABB 3GBA223210-BST 3-Phase motor - IP55

Part Number: 3GBA223210-BST

Quick Summary

3GBA223210-BST is a 3-phase squirrel cage motor designed for heavy-duty industrial drives. Engineers rely on robust performance to reduce downtime and maintenance costs in daily operations. Key protections include IP55 enclosure, ICFL insulation, and IE1 efficiency data to support long service life. This model features a cast-iron frame and durable bearings, delivering reliable torque and quiet operation while simplifying installation alongside ABB drives and control systems. For manufacturers seeking to lower total cost of ownership, this motor integrates seamlessly with existing industrial automation ecosystems and maintenance programs, delivering predictable performance and long service life.

Product Information

Extended Description

3GBA223210-BST ABB: M2BAX 225SMA 6

ABB Type Designation

M2BAX 225SMA 6

Invoice Description

M2BAX 225SMA 6

Product Name

3-Phase squirrel cage motor

Product Type

EBA1__M2BAX_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 90.2 % | Partial Load (75%) 90.2 % | Partial Load (50%) 89.2 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 91.7 % | Partial Load (75%) 91.3 % | Partial Load (50%) 89.9 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

Frame Material

Cast Iron

Frame Size

225

Bearing

6213-2Z/C3

Bearing NDE

6210-2Z/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

284 kg

Gross Weight

294 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Frame and build quality: The cast-iron frame delivers stiffness and vibration damping, improving alignment tolerance and prolonging bearing life. Business impact is reduced downtime and lower maintenance costs during high-load periods, critical for conveyors, pumps, and mixers. Application: Suitable for heavy-duty services in metals processing, mining, and water treatment where reliability matters. IP55 protection and rugged sealing: This enclosure rating protects against dust ingress and water spray, shrinking unwanted downtime in dusty or damp environments. Business impact is extended mean time between failures (MTBF) and lower cleaning and filtration costs. Application: Installations in outdoor or harsh plant environments benefit from reduced ingress risks. IE1 efficiency class: Energy-efficient operation lowers daily energy consumption and heat generation. Business impact is lower operating expense and improved system COP (coefficient of performance). Application: Fans, pumps, and compressors where running costs drive ROI. Bearings and IM class: With 6213-2Z/C3 bearing and IMB5 IM3001 classification, the motor maintains performance under misalignment and load surges. Business impact is quieter operation and longer service life, especially in vertical assemblies or multi-drive banks. Application: Gear-driven conveyors and automated material handling lines. Altitude and temperature tolerance: Rated for 1000 m altitude and 40 °C ambient, this motor remains stable in higher installations and warmer plants. Business impact is broader site applicability and fewer derating concerns. Application: Industrial plants located at elevation or with elevated heat loads. Mounting and rotation options: Direction of rotation is selectable on both sides, simplifying retrofits and machine balancing. Business impact is straightforward integration with existing drives and reduced commissioning time. Application: Upgrades and new installations where space, alignment, and wiring constraints exist.

Get a Quick Quote for a ABB 3GBA223210-BST

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA223210-BST?

Enquire Now

FAQs

This motor uses a standard 3-phase configuration and a 225 frame, making it broadly compatible with common industrial drives and ABB control systems. Plan for top-end terminal box access (D-End top), correct shaft alignment, and compatible mounting feet. Ensure ambient temperature does not exceed 40 °C and altitude remains within 1000 m to avoid derating. Pre-wire and torque all terminal connections per ABB installation guidelines to ensure reliable operation and safety.

The unit is rated IE1 efficiency, with full-load performance data indicating high efficiency under nominal voltage and frequency. At 50 Hz, full load efficiency approaches 90.2%, with partial-load values around 89.2–90.2% depending on load. At 60 Hz, efficiency remains strong, typically around 91.3–91.7% for full load. These figures support lower energy costs in continuous-duty applications like pumps and conveyors.

Yes. The M2BAX-based design supports operation at up to 1000 m altitude and ambient temperatures up to 40 °C. This makes it suitable for industrial sites with elevated installations or warm climates. When planning installations near heat sources or in confined spaces, consider ventilation and cooling provisions to maintain ratings and avoid derating.

Key protections include IP55 enclosure for dust and water exposure, indicating good ingress protection in harsh environments. Insulation class is listed as ICLF, and the motor operates with an IEC-based classification (IC411) for reliability in continuous service. The unit is designed for S1 duty, 6 poles, and a cast-iron frame, ensuring robust performance in continuous operation.

The combination of IP55 protection, durable cast-iron frame, and IE1 efficiency translates to lower maintenance cycles and reduced energy consumption, improving total cost of ownership. Fewer unplanned outages, longer MTBF, and compatibility with existing ABB drives boost productivity. ROI depends on application load profile, duty cycle, and energy pricing, but the design supports quick payback in demanding plants.