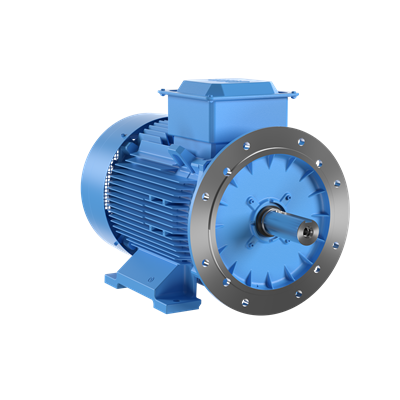

ABB 3GBA252210-BDT 3-Phase squirrel cage motor - IP55

Part Number: 3GBA252210-BDT

Quick Summary

The ABB 3GBA252210-BDT 3-Phase squirrel cage motor delivers reliable, high-torque drive for heavy industry applications such as pumps, conveyors, and fans. Engineers often confront downtime caused by insufficient enclosure protection, inconsistent insulation ratings, or motor misalignment when integrating new drives into legacy lines. This model includes IP55 protection, IC411 insulation, and a robust cast-iron frame rated at 250 millimeters, ensuring durability in dusty, humid environments. With continuous S1 operation, reversible rotation, and straightforward mounting via a D-End top terminal box, it enables reliable performance, easier serviceability, and lower operating costs in modern automation projects.

Product Information

Extended Description

3GBA252210-BDT ABB: M2BAX 250SMA 4

ABB Type Designation

M2BAX 250SMA 4

Invoice Description

M2BAX 250SMA 4

Product Name

3-Phase squirrel cage motor

Product Type

EBA1__M2BAX_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015290

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 92.1 % | Partial Load (75%) 92.0 % | Partial Load (50%) 91.1 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.0 % | Partial Load (75%) 92.6 % | Partial Load (50%) 91.2 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

Frame Material

Cast Iron

Frame Size

250

Bearing

6215-2Z/C3

Bearing NDE

6212-2Z/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

340 kg

Gross Weight

350 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Cast-iron frame and 250 frame size provide a rugged, vibration-damped foundation for demanding processes. Business Impact: Reduced maintenance intervals and longer service life in conveyors, pumps, and processing equipment. Application: Ideal for industrial lines with exposure to dust, moisture, and mechanical shocks. Feature: IP55 enclosure and IC411 insulation deliver robust protection against contaminants and heat, improving uptime in challenging plant environments. Business Impact: Lower risk of insulation failure and equipment downtime, supporting compliant operation in textiles, packaging, and metalworking. Application: Suitable for continuous, in-line applications where reliability is critical. Feature: IE1 efficiency data at 50 Hz and 60 Hz (Full Load 92.1% and 93.0% respectively) enables predictable energy costs. Business Impact: Reduced energy consumption and lower total cost of ownership for long-running line equipment. Application: Conveyor, pump, and fan drives in automation systems with energy targets. Feature: Continuous S1 duty, reversible rotation, and D-End top terminal box simplify installation and maintenance. Business Impact: Faster commissioning, easier retrofits, and flexible system integration. Application: Replacement motors in retrofit projects or new installations requiring reversible operation. Feature: Bearing and IM Class specifications (6215-2Z/C3, 6212-2Z/C3; IMB5 IM3001) combined with a cast-iron frame support high reliability and predictable maintenance cycles. Business Impact: Extended bearing life and consistent performance in high-load environments. Application: Heavy-load conveyors, mixers, and metalworking equipment. Feature: NDE bearing and mechanical specs (4 poles, 340 kg net, 350 kg gross) provide clear installation guidance. Business Impact: Accurate weight and mounting planning reduces downtime and shipping risk. Application: OEM integrations and field service planning.

Get a Quick Quote for a ABB 3GBA252210-BDT

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA252210-BDT?

Enquire Now

FAQs

This motor uses a 250 frame size with 4 poles, designed for a robust, standard-fit on compatible platforms. It features a D-End top terminal box for straightforward wiring, reversible rotation for flexible direction control, and a weight of about 340 kg net. Confirm mounting clearance, shaft alignment, and space for service access to ensure a clean retrofit or new installation in your line.

Electrical data lists IE Class IE1 efficiency with Full Load values of 92.1% at 50 Hz and 93.0% at 60 Hz. The motor is rated for S1 continuous duty, meaning it is designed for constant operation without intermittent rest. These figures support predictable energy use in long-running processes such as pumps and conveyor belts in automation environments.

The motor is IP55, providing protection against dust ingress and water jets from any direction. It does not carry higher IP ratings such as IP65. For harsher washdown or splash zones, additional enclosure or housing would be required. It also conforms to IC411 insulation standards, offering reliable performance within its specified ambient limits.

Yes. The product data specifies an ambient temperature rating of 40 C and an operating altitude up to 1000 meters. These conditions are suited for many standard industrial facilities. When selecting drives or starters, ensure the controller can accommodate the motor’s starting current and that heat dissipation remains within limits at elevated ambients.

Bearings are listed as 6215-2Z/C3 and 6212-2Z/C3 with IM Class IMB5 IM3001, offering solid dynamic load capacity and long service life. Regular maintenance should include periodic bearing inspection, lubrication per interval schedules, and checks of the D-End top terminal box integrity. These measures help sustain reliable operation in demanding line applications such as mining conveyors or heavy-duty pumps.