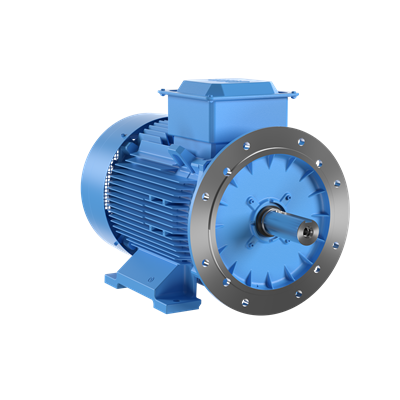

ABB M2BAX 250SMA 4 3-Phase squirrel cage motor - IP55

Part Number: 3GBA252210-BST

Quick Summary

ABB M2BAX 250SMA 4 3-Phase squirrel cage motor delivers reliable, industrial-grade torque for conveyors and pumps. Design challenges like long lead times, high commissioning costs, and uptime risk can derail project timelines. With IP55 protection, IE1 efficiency data, and insulation class ICLF, it meets rugged, continuous-duty requirements in harsh environments, including up to 1000 m altitude and 40 °C ambient. The cast-iron frame and robust bearings support extended service life and easy field maintenance. This motor is well-suited for OEMs, system integrators, and maintenance teams seeking standard, readily serviceable equipment that reduces total cost of ownership and simplifies spare parts planning. Its reversible direction on both ends enhances installation flexibility in space-constrained layouts.

Product Information

Extended Description

3GBA252210-BST ABB: M2BAX 250SMA 4

ABB Type Designation

M2BAX 250SMA 4

Invoice Description

M2BAX 250SMA 4

Product Name

3-Phase squirrel cage motor

Product Type

EBA1__M2BAX_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

China (CN)

Customs Tariff Number

85015290

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 92.1 % | Partial Load (75%) 92.3 % | Partial Load (50%) 91.6 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.0 % | Partial Load (75%) 92.7 % | Partial Load (50%) 91.4 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

Frame Material

Cast Iron

Frame Size

250

Bearing

6215-2Z/C3

Bearing NDE

6212-2Z/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

340 kg

Gross Weight

350 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Cast iron frame and 250 frame size with 340 kg net / 350 kg gross weight. Benefit: Superior structural strength and vibration resistance for heavy-duty equipment, enabling longer service life in demanding applications. Application: Heavy conveyors and pumps in mining and manufacturing environments. Feature: IP55 enclosure and environmental protection. Benefit: Protects windings and internals from dust and water jets, reducing unplanned downtime. Application: Outdoor installations, dusty plants, and wash-down areas in food and chemical processing. Feature: IE1 efficiency data at 50 Hz and 60 Hz. Benefit: Lower energy consumption and operating costs across continuous duty operations. Application: Fans, pumps, and material-handling equipment with steady loads. Feature: Insulation Class ICLF with ambient 40 °C and altitude to 1000 m. Benefit: Higher thermal tolerance and insulation reliability in hot or humid plants, lowering insulation failure risk. Application: Plants with elevated ambient temperatures and moderate altitude constraints. Feature: Bearing setup 6215-2Z/C3 and 6212-2Z/C3 with IMB5 IM3001 class. Benefit: Reduced friction, longer bearing life, and easier maintenance planning. Application: Long-run operation in vibration-prone equipment with minimal service intervals. Feature: Direction of Rotation on both sides and D-End top terminator box. Benefit: Flexible wiring and straightforward panel integration, simplifying retrofits. Application: Reversible drive lines and compact layouts in OEM assemblies.

Get a Quick Quote for a ABB 3GBA252210-BST

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GBA252210-BST?

Enquire Now

FAQs

This motor uses a D-End top terminator box for wiring access, a 250 frame with a cast-iron housing, and a total weight around 340–350 kg. Plan for a sturdy base, proper mounting clearances, and a compatible VFD or starter suited for S1 duty. The reversible rotation option provides flexibility in tight installations and allows simple reorientation without changing wiring strategies.

Yes, the motor supports rotation on both ends, offering bidirectional operation. Direction control is achieved through correct three-phase wiring and protective interlocks. When wiring for reverse rotation, ensure the drive system, guards, and mechanical couplings accommodate the new direction and that all safety protocols are observed during commissioning.

The motor demonstrates IE1 efficiency at 50 Hz with Full Load around 92.1% and at 60 Hz around 93.0%, with slight reductions at partial loads. Energy savings come from its standard efficiency class and low-friction bearings. For continuous-duty applications like pumps and conveyors, typical life-cycle cost reductions are realized through lower operating energy and reduced maintenance needs.

Yes. The motor features IP55 protection and insulation class ICLF, designed for challenging environments. It operates at ambient temperatures up to 40 °C and up to 1000 m altitude, making it suitable for outdoor, dusty, or heat-intensive settings. The 4-pole, cast-iron frame also contributes to durability in demanding industrial applications.

With bearings 6215-2Z/C3 and 6212-2Z/C3, the motor provides low-friction operation and extended bearing life. The robust frame, standard spare parts, and readily available inventory reduce downtime and maintenance costs. For OEMs and end users, this translates to predictable maintenance planning, shorter downtime, and a favorable total cost of ownership.