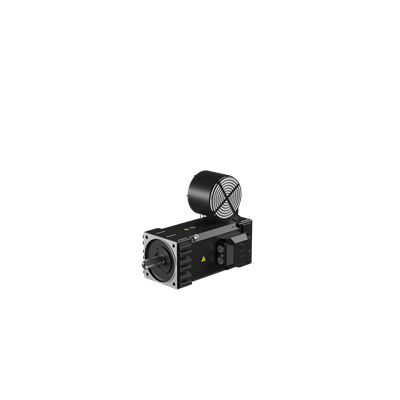

ABB 3GFT132744-SDB High Dynamic Performance Motor - IP23

Part Number: 3GFT132744-SDB

Quick Summary

ABB 3GFT132744-SDB is a high dynamic performance motor for demanding industrial drives. Engineers face efficiency drift and downtime when torque and load vary across automated lines, making reliable, quickly-responsive motors essential. With IP23 housing, insulation class ICLH, and IC06 ratings, this motor is built for dependable operation in standard factory environments and modest outdoor installations. The design supports energy efficiency and long life, helping reduce lifecycle costs while enabling smoother throughput and lower maintenance overhead. For buyers evaluating motors & drives, this model offers a compelling combination of performance, durability, and install-ready compatibility.

Product Information

ABB Type Designation

M3FT 132D 4

Invoice Description

M3FT 132D 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015290

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

370 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 90.6 % | Partial Load (75%) 91.7 % | Partial Load (50%) 92.5 %

IE Class Data (60 Hz)

IE Class NA | Full Load (100%) 91.7 % | Partial Load (75%) 92.3 % | Partial Load (50%) 92.2 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

132

Bearing

6310-2Z

Bearing NDE

6310-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 carton

Product Net Weight

140 kg

Gross Weight

145 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: High dynamic performance motor design enables rapid torque response and precise speed control. Business Impact: Improves cycle times and reduces bottlenecks in high-speed packaging, extrusion, and material handling lines. Application: Ideal for automated production cells requiring quick acceleration and load adaptability, with energy-efficient operation. Feature: IP23 protection and EN enclosure compatibility provide safe operation in factory floors and light outdoor environments. Business Impact: Simplifies installation, lowers enclosure costs, and supports compliant operation where dust and incidental moisture may be present. Application: Suitable for general machinery drives, conveyors, and machine tools in standard industrial settings. Feature: Aluminum frame and 132 frame size offer a robust yet lightweight construction. Business Impact: Easier handling during installation, reduced overall system weight, and improved energy efficiency. Application: Retrofits and new installations on compact CNCs and automated conveyors. Feature: Insulation Class ICLH and 1000 m altitude tolerance boost reliability under varied ambient conditions. Business Impact: Enhanced insulation performance reduces thermal wear and extends motor life in demanding environments. Application: Plants with higher elevations or hotter production zones. Feature: Duty S9 and ambient 40 °C capability ensure continuous operation under sustained loads. Business Impact: Maximizes uptime, lowers maintenance cycles, and supports long production runs. Application: Continuous processes in plastics, metals, and packaging lines. Feature: 370 V operation, 4-pole design, and IP23 with bidirectional rotation support installation flexibility. Business Impact: Smooth integration with existing drives and flexible motor orientation. Application: Retrofit projects and new builds in multi-axis automation systems.

Get a Quick Quote for a ABB 3GFT132744-SDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT132744-SDB?

Enquire Now

FAQs

ABB 3GFT132744-SDB installation should align with the 132 frame footprint and aluminum housing to ensure proper mounting and alignment with existing conveyors or machine tool beds. Verify the Terminator Box Location (N-End right side) for wiring access, confirm the bidirectional rotation capability for flexible drive orientation, and ensure ambient temperature does not exceed 40 °C in service areas. Use compatible VFDs rated for 370 V operation and confirm the IP23 enclosure protects against dust and light moisture as expected in workshop environments.

Key specifications include a 132 frame size with aluminum construction, a 4-pole design, and a 370 V motor operational voltage. The motor is rated for S9 duty, supports IP23 protection, and uses insulation class ICLH. It is designed for continuous operation in ambient up to 40 °C and up to 1000 m altitude, with a bidirectional rotation option to fit varied installation layouts.

Yes, the 3GFT132744-SDB is designed for high dynamic performance with rapid torque response, which helps stabilize speeds during fast packaging cycles. Its S9 duty and robust aluminum frame support long operation under continuous load, reducing cycle times and accelerating throughput while maintaining reliability. Ensure compatibility with the line’s drive system and confirm cooling is adequate for sustained operation.

This motor carries IP23 protection for moderate protection against ingress, IC LH insulation class for reliable insulation at elevated temperatures, and IC06 classification indicating suitable performance under specified duty cycles. The unit’s origin from Finland (FI) and the 85015290 customs tariff code support compliant procurement for international supply chains and import documentation.

Maintenance focuses on bearing life (6310-2Z bearings) and periodic checks of the aluminum frame for any mounting looseness. Because of its efficient design and S9 duty compatibility, expected ROI comes from higher uptime, reduced replacement cycles, and lower energy consumption compared to non-HDP motors. For retrofit projects, verify mounting compatibility, wiring tolerances, and drive integration to maximize efficiency gains.