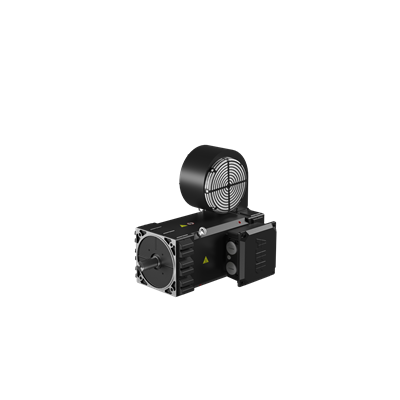

ABB 3GFT162714-SDB High dynamic performance motors - IP23

Part Number: 3GFT162714-SDB

Quick Summary

ABB 3GFT162714-SDB High dynamic performance motors power demanding drives in conveyors and processing lines. Customers struggle with reliability under high torque peaks and tight installation spaces. They meet IP23 protection, IC LH insulation, and S9 duty for reliable continuous operation in harsh manufacturing environments. Designed for industrial motors and energy-efficient drives, these units deliver lower lifecycle costs through robust bearings, a durable aluminum frame, and smart compatibility with standard ABB drive systems. For design engineers and procurement teams, the combination of rugged IP23 protection, high‑duty capability, and a global service network translates to fewer change orders, faster commissioning, and predictable ROI.

Product Information

ABB Type Designation

M3FT 160A 4

Invoice Description

M3FT 160A 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015290

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

370 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 91.9 % | Partial Load (75%) 92.5 % | Partial Load (50%) 92.2 %

IE Class Data (60 Hz)

IE Class NA | Full Load (100%) 92.8 % | Partial Load (75%) 93.0 % | Partial Load (50%) 92.4 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

160

Bearing

6312-2Z

Bearing NDE

6312-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

209 kg

Gross Weight

219 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: High dynamic performance motors deliver rapid torque rise and precise speed control. Impact: Enables tighter process control, shorter start-up times, and reduced cycle times in demanding drives. Application: conveyors, presses, and packaging lines where timing matters. Feature: IP23 protection and IC LH insulation provide rugged operation in typical factory environments. Impact: reduces unplanned downtime from dust, moisture, and thermal stress while maintaining insulation integrity at elevated ambient temperatures. Application: automation lines in metalworking, plastics, and automotive assembly. Feature: Aluminum frame and 160 frame size offer a robust yet lighter chassis with efficient heat dissipation. Impact: simplifies installation, lowers mounting costs, and improves reliability in heat-prone facilities. Application: retrofit projects and space-constrained installations. Feature: Bearing 6312-2Z is sealed and maintenance-friendly. Impact: extends bearing life, reduces maintenance cycles, and improves reliability in continuous-duty applications. Application: heavy-duty conveyors and mixers. Feature: 4-pole, S9 duty ensures stable operation under heavy loads. Impact: consistent speed regulation, reduced vibrations, and minimized wear over long production runs. Application: extrusion lines and metal forming. Feature: 370 V operating voltage with altitude up to 1000 m and ambient up to 40 °C. Impact: broad geographic applicability with fewer deratings and simpler electrical planning. Application: global manufacturing sites. Feature: Direction of rotation on both sides provides installation flexibility. Impact: simplifies motor alignment and reduces commissioning time. Application: multi-assembly lines and variable-speed drives. Feature: Net weight 209 kg (219 kg gross) and aluminum frame support robust, durable construction while enabling easier handling. Impact: safer transport and installation, with better heat management. Application: large-scale industrial installations. Feature: WEEE category 4 and Finland origin reflect quality and compliance. Impact: supports regulatory reporting and sustainable asset management. Application: global compliance programs and audits.

Get a Quick Quote for a ABB 3GFT162714-SDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT162714-SDB?

Enquire Now

FAQs

Carefully assess voltage compatibility (370 V), frame size 160, and mounting orientation (N-End right side as standard). The motor’s aluminum frame lightens handling and heat dissipation improves enclosure planning. Ensure IP23 protection is suitable for the environment and that available spare parts align with the 6312-2Z bearings and IMB35 IM2001 mounting codes for a smooth retrofit.

At 50 Hz, Full Load efficiency typically aligns with IE Class data around 91.9% with similar partial-load figures near 92.5% at 75% load and 92.2% at 50% load. At 60 Hz, Full Load efficiency is about 92.8% with 93.0% and 92.4% for 75% and 50% loads respectively. Expect consistent torque, stable speed control, and reduced energy costs in continuous drives.

Yes. IP23 protection and an altitude rating up to 1000 m make the 3GFT162714-SDB appropriate for standard factory floors and slightly elevated facilities. With ambient temperatures up to 40 °C, the motor maintains performance without excessive derating, provided installation follows manufacturer guidelines and proper cooling is maintained.

The 6312-2Z bearings reduce friction and wear, extending service life and reducing maintenance cycles in continuous-duty applications. The aluminum frame offers better heat dissipation and lighter weight, lowering handling and mounting costs. Overall, this translates to lower maintenance frequency and improved uptime, contributing to a favorable return on investment in heavy-duty lines.

S9 duty indicates a steady, heavy-load operation suitable for long production runs. It supports reliable speed regulation and torque delivery under sustained loads, minimizing thermal stress and vibration. This makes the motor ideal for extrusion, metal forming, and other continuous-process applications where uptime and precision matter.