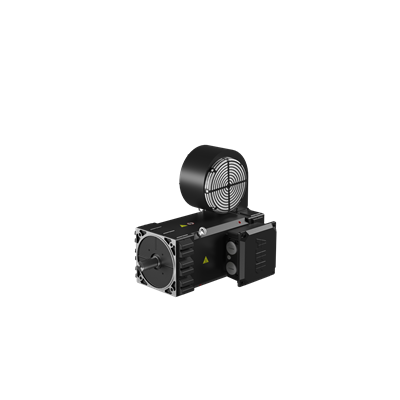

ABB 3GFT162716-SDB High dynamic performance motors - IP23

Part Number: 3GFT162716-SDB

Quick Summary

ABB 3GFT162716-SDB high dynamic performance motors are designed for demanding industrial drives and process automation. Many installations struggle with motor efficiency, heat buildup, and unplanned downtime under continuous operation. This motor delivers reliable performance through a robust insulation system and carefully balanced efficiency ratings, while IP23 protection adds resilience in typical plant environments. With insulation class ICLH and IE1-rated efficiency at both 50 Hz and 60 Hz, it provides predictable energy use across duty cycles. By combining a rugged aluminum frame, a 160 frame size, and a four-pole design, it reduces vibration and maintenance while supporting easy integration with standard ABB drives. For procurement teams, this translates to lower lifecycle costs and smoother commissioning on upgrades and new lines.

Product Information

ABB Type Designation

M3FT 160A 4

Invoice Description

M3FT 160A 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

370 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 93.2 % | Partial Load (75%) 93.5 % | Partial Load (50%) 92.9 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.6 % | Partial Load (75%) 93.4 % | Partial Load (50%) 92.5 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

160

Bearing

6312-2Z

Bearing NDE

6312-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

209 kg

Gross Weight

219 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Aluminum frame and 160 frame size deliver a robust, lightweight yet sturdy housing that minimizes vibration and simplifies installation in confined spaces. Business Impact: Lower mounting complexity and cleaner alignment with existing conveyors or pumps reduce commissioning time and maintenance costs. Application: Suitable for packaging lines and automated material handling where space is at a premium. Feature: IE1 efficiency with full-load values of 93.2–93.6% across 50/60 Hz improves energy consumption and operating costs. Business Impact: measurable energy savings and improved regulatory compliance in energy audits. Application: Fans, pumps, and process equipment in continuous-duty environments. Feature: IP23 protection and insulation class ICLH provide reliable operation in interior, non-extreme environments. Business Impact: reduced risk of moisture ingress and insulation degradation, extending service life. Application: General purpose industrial drives and assembly lines. Feature: 4-pole, 370 V operation and directional flexibility (Both sides) enable precise torque control and reversible operation. Business Impact: easier drive integration and system topology optimization, lowering design iteration time. Application: Conveyor systems and mixer installations where bidirectional operation is beneficial. Feature: Aluminum frame and bearing 6312-2Z with IMB35 IM2001 classification support longevity and smoother maintenance cycles. Business Impact: less downtime, easier bearing replacement, lower maintenance costs over the motor’s life. Application: Heavy-duty industrial environments with frequent starts and stops. Feature: Terminator box located on N-End right side simplifies electrical routing and cabinet layout. Business Impact: reduces field wiring complexity and speeds installation in existing machine frames. Application: Retrofit projects and new builds with standard ABB control architectures.

Get a Quick Quote for a ABB 3GFT162716-SDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT162716-SDB?

Enquire Now

FAQs

Install the motor in a compatible 160 frame base with proper alignment to minimize vibration. Ensure a 370 V supply and check installation constraints: altitude up to 1000 m and ambient temperature around 40 °C. Use appropriate couplings and a base plate, and route wiring to the N-End right side terminal box for straightforward electrical connections. Verify bearing accessibility (6312-2Z) and mount torque per OEM guidelines to maintain reliability.

This model is explicitly marketed as a high dynamic performance motor, featuring a 4-pole design and robust IE1 efficiency metrics at both 50 Hz and 60 Hz. The aluminum frame and IP23 protection support rapid torque response with reliable operation in typical plant environments, while maintaining energy efficiency and reduced system heat generation on conveyors, pumps, and packaging lines.

It is designed for steady-state S9 duty with a 370 V supply and can be integrated with appropriate variable frequency drives that match the voltage and insulation ratings. For speed control, choose a drive compatible with the motor’s 370 V rating and consult ABB documentation for wiring and safety clearances. Ensure cooling and protective features align with the chosen drive configuration.

Key standards include IP23 ingress protection and insulation class ICLH, supporting reliability in indoor, non-harsh environments. The motor is rated IE1 for energy efficiency across 50 Hz and 60 Hz. Additional considerations include WEEE category 4 and country of origin Finland (FI), which influence compliance and end-of-life handling in industrial installations.

The 6312-2Z bearings, aluminum frame, and robust construction reduce downtime and maintenance needs, improving mean time between failures. IE1 efficiency lowers energy costs, while durable components lower replacement frequency. For ROI, expect lower lifecycle costs and faster commissioning when upgrading lines or installing new packaging or conveyor systems.