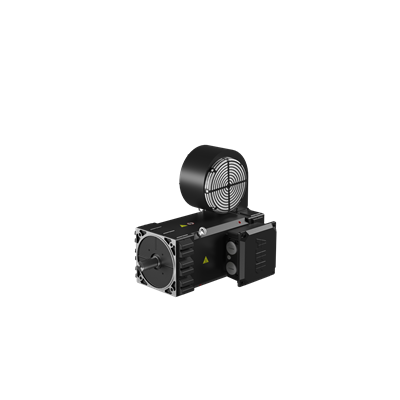

ABB 3GFT162734-SDB M3FT 160C 4 High Dynamic Motors - IP23

Part Number: 3GFT162734-SDB

Quick Summary

ABB 3GFT162734-SDB M3FT 160C 4 high dynamic motors power precise torque and reliable operation in demanding automation and packaging lines. Engineers often contend with vibration, startup surges, and uptime pressures; this motor’s robust aluminum frame, IP23 enclosure, and precision bearings address those challenges from day one. Key certifications include IP23 protection, insulation class ICLH, and verifiable IE Class performance data across 50 and 60 Hz, ensuring predictable behavior in global deployments. The design supports easy integration with ABB and third-party drives, while providing strong lifecycle value through energy efficiency and reduced maintenance needs. This combination translates to lower total cost of ownership and smoother production flows for mid-to-large scale operations.

Product Information

ABB Type Designation

M3FT 160C 4

Invoice Description

M3FT 160C 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

360 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 92.7 % | Partial Load (75%) 93.2 % | Partial Load (50%) 92.8 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.4 % | Partial Load (75%) 93.5 % | Partial Load (50%) 92.8 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

160

Bearing

6312-2Z

Bearing NDE

6312-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

266 kg

Gross Weight

276 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

The M3FT 160C 4 motor features a high dynamic performance design with a 4-pole configuration and 360 V operation, delivering fast torque response and improved line throughput for conveyors and packaging equipment. This translates to shorter cycle times and reduced process jitter, enabling tighter control of production lines while maintaining energy efficiency in continuous operation. Its aluminum frame 160 keeps weight manageable without sacrificing rigidity, supporting simpler installation and robust mounting in space-constrained cabinets. IP23 protection and insulation class ICLH provide reliable operation in typical factory environments, guarding against dust and moisture ingress and extending service life in demanding environments. The 6312-2Z bearings and IMB35 IM2001 classification reduce wear and maintenance intervals, which lowers downtime and maintenance costs. The terminator box location at N-End right side simplifies wiring layouts and cabling harnesses, speeding up installation and service. With Finland origin and a clear minimum order quantity of one piece, procurement is predictable and scalable for growing automation programs. Overall, the motor’s compatibility with standard 160 frame dimensions and 360 V supply aligns with common control architectures, enabling smoother upgrades and retrofit projects across diverse industries.

Get a Quick Quote for a ABB 3GFT162734-SDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT162734-SDB?

Enquire Now

FAQs

For installation, use the 160 frame aluminum housing with the specified IMB35 IM2001 bearing arrangement and mount the motor with the Terminator Box located at the N-End right side. This configuration supports straightforward wiring, minimizes space requirements in control panels, and aligns with standard IEC mounting patterns. Appropriately sized couplings and shaft seals should be selected to maintain IP23 protection and performance across temperature and altitude variations up to 1000 m.

IE Class data at 50 Hz shows Full Load efficiency around 92.7–93.2%, with similar partial-load values near 93% depending on operating point. At 60 Hz, Full Load efficiency is approximately 93.4%. These figures indicate strong energy efficiency for continuous operation, reducing running costs on conveyors and process lines while maintaining stable torque characteristics across load ranges.

This motor excels in packaging lines, material handling, and process equipment where precise torque control and fast transient response matter. The 4-pole design provides robust dynamic performance suitable for conveyors, fan drives, and small machine tools. Its IP23 enclosure and aluminum frame help ensure reliable operation in typical factory environments, making it a strong choice for automation projects with space and protection constraints.

Key certifications include IP23 protection for enclosure integrity, IC LH insulation class for high-temperature resistance, and verifiable IE Class data across frequency ranges. These features support regulatory compliance, safe operation under typical industrial conditions, and predictable performance across different power grids. The insulation class and duty rating ensure reliability in continuous service, reducing risk of insulation failure in demanding processes.

The motor’s energy efficiency at both 50 Hz and 60 Hz, combined with robust bearings (6312-2Z) and IM class design, contributes to lower energy and maintenance costs over a long service life. An immediate benefit is reduced downtime due to reliable performance and easier installation thanks to the N-End terminator box. The Finland-origin supply and single-piece MOQ also support predictable procurement and faster project ramp-up, enhancing overall ROI.