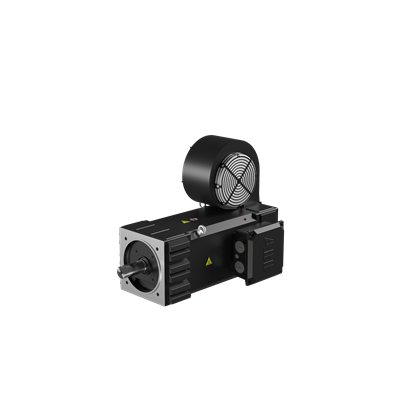

ABB 3GFT182711-SDB Motors & Drives - IP23

Part Number: 3GFT182711-SDB

Quick Summary

ABB 3GFT182711-SDB high dynamic performance motor is designed for precise servo-driven automation in demanding manufacturing environments. This model helps address integration and calibration challenges that commonly cause line downtime during scale-up. It features IP23 protection, insulation class ICLH, and robust IC06 construction to withstand harsh conditions. With a 380 V operating voltage, 4-pole design, and an 180 frame, it supports reliable torque delivery and smooth ramping across processes. For operators seeking energy efficiency and quicker commissioning, this motor aligns with IEC performance data while supporting scalable deployment and lower total cost of ownership.

Product Information

ABB Type Designation

M3FT 180A 4

Invoice Description

M3FT 180A 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI) | China (CN)

Customs Tariff Number

85015290

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

380 V

Operating Frequency (fsw)

34.300 Hz

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 89.4 % | Partial Load (75%) 91.0 % | Partial Load (50%) 89.9 %

IE Class Data (60 Hz)

IE Class NA | Full Load (100%) 90.3 % | Partial Load (75%) 91.3 % | Partial Load (50%) 91.5 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

180

Bearing

6314-2Z

Bearing NDE

6314-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

384 kg

Gross Weight

394 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

IP protection and electrical robustness translate to reduced maintenance cycles in dusty or humid environments, enabling longer run times on packaging lines and conveyors. The high dynamic performance motor delivers precise speed control, which directly lowers reject rates and improves throughput in automated assembly cells. Aluminum frame construction reduces weight, easing installation and enabling simpler retrofits on existing lines without compromising rigidity. The 4-pole design provides predictable torque characteristics, supporting consistent performance in continuous operation and during demanding load changes. The 6314-2Z bearings enhance longevity and reduce replacement costs, while the IMB35/IM2001 class construction supports reliable operation in factory floors with limited space. The motor’s IE Class data indicates energy efficiency gains across full- and partial-load conditions, contributing to lower operating expenses over the equipment life. With a S9 duty type and 380 V supply, it is well suited for continuous industrial automation tasks, including material handling, packaging, and extrusion processes.

Get a Quick Quote for a ABB 3GFT182711-SDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT182711-SDB?

Enquire Now

FAQs

The ABB 3GFT182711-SDB uses a standard 180 frame size and a four-pole configuration, ensuring compatibility with common motor mounts and couplings used in industrial drives. Its aluminum frame, 6314-2Z bearings, and IM class ratings support straightforward retrofits in existing lines, while the 380 V supply and IP23 protection align with typical wiring and enclosure standards found on packaging, conveying, and automation equipment.

Best-fit applications include servo-driven automation on packaging lines, conveyors, and robotic cells where precise speed control and rapid acceleration are essential. The motor’s high dynamic performance, 4-pole design, and S9 duty rating make it well suited for continuous operation under heavy loads, with reliable startup and ramping in demanding manufacturing environments.

Key ratings include a 380 V operating voltage, IP23 ingress protection, and a 4-pole configuration with a 180 frame size. Insulation class ICLH supports harsh environments, and the IE Class data provides efficiency performance at full and partial loads. The motor also features a voltage code D and a duty type of S9 for continuous operation in industrial setups.

Consider mounting on a compatible 180 frame base with appropriate fasteners and alignment to minimize vibration. Note that the Terminator Box Location is N-End right side, and the IM class is IMB35/IM2001, which informs mounting clearances and service access. With an aluminum frame, ensure adequate ventilation, and verify that the 380 V supply, altitude (up to 1000 m), and ambient temperature (up to 40 C) are within spec for reliable operation.

The combination of high dynamic efficiency, robust bearings, and insulation class design reduces energy waste and wear, lowering operating costs and maintenance frequency. The IE Class data indicates better performance across loads, while the 6314-2Z bearings support longer service life, translating to fewer unplanned downtimes and a faster return on investment in automated line projects.