ABB 3GFT182712-HDB Motors & Drives - IP23

Part Number: 3GFT182712-HDB

Quick Summary

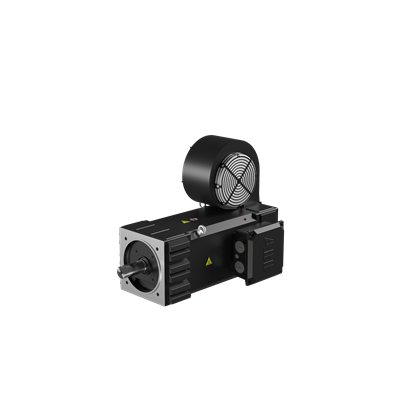

ABB 3GFT182712-HDB high dynamic performance motors optimize precise motion in demanding manufacturing lines. Engineers face downtime, wear, and torque variability when upgrading automation assets. They deliver IP23 protection, insulation class ICLH, and reliable IE Class performance data for robust operation. In practice, these motors enable energy-efficient automation and seamless integration with ABB drives, delivering lower total cost of ownership and faster time-to-value for industrial motor applications. Designed for 4-pole operation with a rugged aluminum frame, they suit both clean-room environments and rugged factory floors.

Product Information

ABB Type Designation

M3FT 180A 4

Invoice Description

M3FT 180A 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 91.8 % | Partial Load (75%) 92.3 % | Partial Load (50%) 91.9 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 92.6 % | Partial Load (75%) 93.0 % | Partial Load (50%) 92.4 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

180

Bearing

6314-2Z

Bearing NDE

6314-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

384 kg

Gross Weight

394 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

4-pole design delivers stable torque and quick acceleration, reducing cycle times and wear on drive systems, directly boosting throughput on high-speed packaging lines. The aluminum frame provides a lightweight yet sturdy enclosure, simplifying installation and reducing mounting stresses while contributing to overall energy efficiency. IP23 protection and insulation class ICLH improve reliability in semi-enclosed environments, supporting longer maintenance intervals and lower replacement costs. The motor’s 180 frame and bearing combo, including 6314-2Z bearings, delivers smooth operation with reduced vibration, enhancing machine uptime in continuous S9 duty cycles. Compatibility with standard ABB drives and the IMB35 IM2001 class ensures straightforward integration, while the N-End right side terminator box location simplifies cabling and service. Altitude and ambient temperature ratings (up to 1000 m and 40 °C) expand deployment options across multiple facilities, improving spare-part planning and uptime across OEM and end-user installations. Overall, these motors offer measurable efficiency gains, robust lifecycle performance, and a clear path to lower total cost of ownership in industrial automation projects.

Get a Quick Quote for a ABB 3GFT182712-HDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT182712-HDB?

Enquire Now

FAQs

Begin with proper mounting on a rigid base to minimize vibration. Use the N-End right side terminator box for clean cabling, route cables away from heat sources, and ensure alignment with the drive system. Confirm voltage code D and S9 duty compatibility, and leverage compatible ABB drives to ensure smooth control and protection features.

IE Class data shows at 50 Hz full-load efficiency around 91.8%, with 75% load at 92.3% and 50% load at 91.9%. At 60 Hz, full-load efficiency is about 92.6%, with 75% load at 93.0% and 50% load at 92.4%. These figures indicate strong energy performance across common industrial frequencies.

Yes. The M3FT designation supports S9 continuous-duty profiles, providing reliable torque over long operation periods. With a 4-pole design and strong bearings (6314-2Z), the motor maintains stable performance under frequent start-stop cycles typical of packaging and material handling lines.

The motor uses an aluminum frame sized 180 with a 4-pole configuration and 6314-2Z bearings. The IM class is IMB35 IM2001, and the terminator box location is N-End right side, which simplifies cabling. Weight figures are 384 kg net and 394 kg gross, suitable for solid mounting on rigid frames in controlled environments.

The combination of high dynamic performance, robust IP23 protection, and ICLH insulation translates to longer service intervals and fewer unplanned downtime events. Its compatibility with ABB drives, reliable bearings, and lightweight aluminum frame reduce installation and maintenance costs while improving energy efficiency and overall lifecycle value for OEMs and end users.