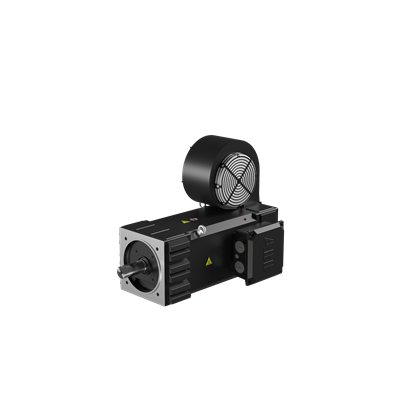

ABB 3GFT182714-HDB High dynamic performance motors - IP23

Part Number: 3GFT182714-HDB

Quick Summary

High dynamic performance motors is a core ABB offering engineered for fast response and precise torque in demanding industrial drives. This model is ideal for applications where rapid acceleration and tight speed control cut cycle times and energy waste. Users often wrestle with excessive heat, bearing wear, and duty-cycle mismatches; ABB addresses these with a robust aluminum frame, 180 mm footprint, and a reliable 4-pole design. With IP23 protection and IC06 insulation, the motor tolerates moderate dust and moisture while maintaining insulation integrity. IE1 efficiency and a 40 °C ambient rating translate to lower operating costs and higher uptime, while a practical N-end right-side terminator box streamlines panel wiring. In short, this motor combines ABB reliability with project-ready, industry-focused specifications.

Product Information

ABB Type Designation

M3FT 180A 4

Invoice Description

M3FT 180A 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 93.1 % | Partial Load (75%) 93.0 % | Partial Load (50%) 92.2 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

180

Bearing

6314-2Z

Bearing NDE

6314-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

384 kg

Gross Weight

394 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: 4-pole high dynamic performance with precise torque delivery -> Benefit: Fast start-stop response and stable speed control reduce cycle times and energy use -> Application: Conveyors, packaging lines, and extrusion drives. Feature: Aluminum frame with 180 frame size -> Benefit: Lighter, rigid construction facilitates installation and reduces overall system weight, improving handling and energy efficiency -> Application: OEM machinery and retrofit projects where weight and rigidity matter. Feature: IP23 enclosure, IC06 insulation, and IE1 efficiency -> Benefit: Enhanced protection for moderate dust/moisture environments and reliable insulation life, with lower energy consumption over the service life -> Application: Factory floors and automated lines operating at up to 40 °C ambient. Feature: Direction of Rotation on both sides -> Benefit: Flexible wiring and routing options simplify installation and maintenance -> Application: Reversible conveyors and multi-pass machinery layouts. Feature: Bearing 6314-2Z, IM class IMB35 IM2001 -> Benefit: Long bearing life and robust mechanical alignment reduce downtime and maintenance costs -> Application: Heavy-duty drive systems with demanding loads. Feature: Terminator box location N-End right side, mounting compatibility -> Benefit: Easier panel integration and faster commissioning -> Application: Standardized installations with minimized wiring complexity.

Get a Quick Quote for a ABB 3GFT182714-HDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT182714-HDB?

Enquire Now

FAQs

Prepare for a right-side terminator box (N-End), ensure mounting aligns with a 180 frame size, and verify the 4-pole configuration matches your drive system. Weigh the 384 kg net weight and 394 kg gross to plan support structures, and confirm the ambient 40 °C rating suits your facility layout and airflow. Use proper cable glands and protection to preserve IP23 integrity.

Yes, the 3GFT182714-HDB uses an IP23 enclosure for moderate protection against dust and moisture and features insulation class ICLH with IC06 classification. This combination supports reliable operation in typical factory environments up to 40 °C ambient and at elevations near 1000 m, helping ensure continuity in standard production lines.

The motor is not a two-speed model. It is rated for continuous S9 duty, suitable for intermittent but heavy workloads typical of long production runs with periodic bursts. This aligns with applications requiring robust torque at consistent loads rather than multi-speed versatility.

Ideal for conveyors, packaging lines, and extrusion drives where rapid acceleration and precise speed control drive throughput. The 4-pole design and IE1 efficiency support tight process control, while the aluminum frame and bearing selection improve reliability in automated manufacturing environments.

Minimum order quantity is 1 piece, with 1 piece per order, and the unit originates from Finland (FI). The N-End right-side terminator box and 180 frame size simplify installation, while the 6314-2Z bearings and IM class specifications support long service life. Tariff code 85015381 and the aluminum frame enable straightforward integration with common ABB drive systems.