ABB 3GFT182721-HDB Motors & Drives - IP23

Part Number: 3GFT182721-HDB

Quick Summary

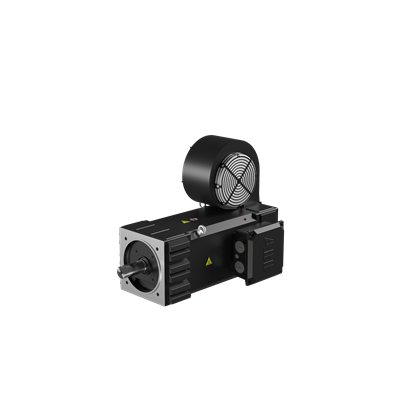

ABB 3GFT182721-HDB is a high-dynamic-performance motor designed for demanding industrial drives and automated production lines. This model delivers rapid torque response and precise speed control essential for packaging, material handling, and process automation. Engineers often struggle with integration, thermal management, and long-term reliability in demanding environments. The combination of a robust aluminum frame, IP23 enclosure, and IC LH insulation helps ensure dependable operation under 40 °C ambient conditions up to 1000 m altitude. With a 4-pole design and a sturdy bearing solution, it supports steady performance across heavy-duty cycles. By aligning with ABB drive systems and standard industry interfaces, it also reduces integration risk and project lead times, delivering measurable business value through uptime and efficiency improvements.

Product Information

ABB Type Designation

M3FT 180B 4

Invoice Description

M3FT 180B 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 89.9 % | Partial Load (75%) 91.1 % | Partial Load (50%) 89.9 %

IE Class Data (60 Hz)

IE Class NA | Full Load (100%) 90.9 % | Partial Load (75%) 91.7 % | Partial Load (50%) 91.7 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

180

Bearing

6314-2Z

Bearing NDE

6314-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

436 kg

Gross Weight

446 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature → Business Impact → Application: High dynamic performance with a 4-pole, 180 frame enables rapid torque response and precise speed control, translating to reduced cycle times on packaging lines and faster material handling. Application: automation systems that demand tight speed regulation and quick acceleration. Feature → Business Impact → Application: Aluminum frame reduces weight while maintaining stiffness, easing installation and retrofit projects and lowering handling costs. Application: retrofits and new equipment in existing lines where installation speed matters. Feature → Business Impact → Application: IP23 enclosure and IC LH insulation enable reliable operation in standard workshop environments up to 40 °C ambient, increasing uptime and reducing cooling requirements. Application: general automation in production floors with moderate environmental exposure. Feature → Business Impact → Application: 6314-2Z bearings with IMB35 IM2001 configuration provide durability for S9 duty cycles, extending mean time between maintenance and lowering maintenance costs. Application: continuous operation in conveyors, presses, and robotic actuators. Feature → Business Impact → Application: Easy integration with ABB drive systems and familiar interfaces, shortening commissioning times and reducing project risk. Application: new installations and upgrades aligned with existing ABB control architectures. Feature → Business Impact → Application: Country of origin Finland (FI) ensures consistent supply chain and quality standards, supporting regional procurement strategies. Application: supplier consolidation and compliance in global manufacturing networks.

Get a Quick Quote for a ABB 3GFT182721-HDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT182721-HDB?

Enquire Now

FAQs

The 3GFT182721-HDB is designed for seamless integration with ABB drive systems and standard industrial interfaces. It supports common 3‑phase control schemes, a robust aluminum frame for easy mounting, and a 4‑pole configuration that aligns with typical ABB motor drives. For retrofit projects, verify connector type and wiring conventions per ABB installation guides to minimize commissioning time and ensure repeatable performance.

At an ambient temperature of up to 40 °C, the motor maintains reliable speed control and torque delivery thanks to its IC LH insulation and IP23 enclosure. The design accommodates up to 1000 m altitude, ensuring consistent performance in moderate elevation settings. For peak loads, allow adequate cooling and monitor bearing wear in high-cycle applications to sustain efficiency over the motor’s life.

Yes. The 3GFT182721-HDB is engineered for high dynamic response with a 4-pole configuration and a robust 6314-2Z bearing setup (IMB35 IM2001). It supports S9 duty, providing reliable operation under continuous, demanding cycles typical of packaging lines and material-handling systems. Proper ventilation and regular bearing maintenance will maximize uptime and minimize unplanned downtime.

Key protections include an IP23 enclosure rating for general workshop environments and IC LH insulation for dependable electrical isolation. The aluminum frame contributes to durability while keeping weight manageable for easier installation. While CE/UL specifics aren’t listed here, the IP rating and insulation class provide essential compliance context for standard industrial operating conditions.

The motor’s combination of high dynamic performance, IP23 protection, and robust bearings contributes to improved throughput and reduced downtime. With a lighter aluminum frame, simplified mounting, and compatibility with ABB drives, commissioning times are shorter and maintenance intervals can be extended. In retrofit projects, the predictable performance and lower total cost of ownership translate into faster payback and ongoing operational savings.