ABB 3GFT182726-HDB 3FTB__M3FT__HDP__IP23_ - IP23

Part Number: 3GFT182726-HDB

Quick Summary

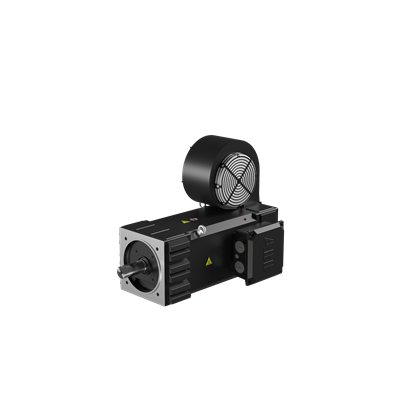

ABB 3GFT182726-HDB high dynamic performance motors power demanding automation applications across packaging, extrusion, and conveyor lines. The challenge often is delivering precise torque and smooth acceleration without sacrificing energy efficiency or reliability in harsh factory environments. These motors meet IP23 protection, IE1 efficiency, and IC LH insulation, supporting safe operation from ambient temperatures up to 40 °C and at altitudes around 1000 m. With a robust aluminum frame, a 180 frame size, and a four-pole design, they offer consistent performance while simplifying installation in compact spaces. For procurement teams, the no make-to-order policy and Finland-origin supply provide predictable lead times and regulatory alignment.

Product Information

ABB Type Designation

M3FT 180B 4

Invoice Description

M3FT 180B 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 94.0 % | Partial Load (75%) 93.3 % | Partial Load (50%) 92.0 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

180

Bearing

6314-2Z

Bearing NDE

6314-2Z

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

436 kg

Gross Weight

446 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: IP23 protection and aluminum frame provide rugged enclosure for challenging environments, reducing field failures and maintenance costs. Business impact: lower downtime, longer service intervals, and easier outdoor or semi-enclosed installation. Application: conveyors and packaging lines where dust, humidity or incidental splashes are common, yet reliable operation is required. Feature: IE1 efficiency with Full Load 94% and Partial Load values (75%: 93.3%, 50%: 92.0%) improves energy performance and operating cost profiles. Business impact: measurable energy savings over motor life and better compliance with energy targets. Application: continuous process lines and material handling that cycle through varying loads. Feature: 4-pole design, 180 frame size, and aluminum construction enable robust torque response with lighter frame mass, supporting easier mounting and heat dissipation. Business impact: higher starting torque and improved dynamic performance with reduced cooling requirements. Application: high-demand drives like extrusion or winding where rapid acceleration matters. Feature: direction of rotation both sides and N-End right side terminator box layout simplify mechanical integration, wiring, and service access. Business impact: faster commissioning, flexible layouts, and reduced field rework. Application: retrofit projects and new installations in constrained plant footprints. Feature: 436 kg net weight and 446 kg gross weight indicate stable inertia and reliable performance under load, with IM class compatibility for standardized mounting. Business impact: predictable handling, safer transport, and straightforward installation. Application: heavy-duty motor installations requiring solid, vibration-resistant operation. Feature: country of origin Finland and customs tariff 85015381 support regulatory compliance and predictable import processes. Business impact: streamlined procurement, traceability, and conformity with local sourcing preferences. Application: global supply chains seeking consistent origin data and tariff classification.

Get a Quick Quote for a ABB 3GFT182726-HDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT182726-HDB?

Enquire Now

FAQs

This motor uses a 180 frame aluminum construction with a standard IM class (IMB35 IM2001) and a N-End right side terminator box location, enabling versatile mounting in both horizontal and vertical orientations. Its direction of rotation is defined as both sides, so you can adapt to existing conveyors or drives without costly reconfigurations. For installation, ensure adequate cooling in ambient temperatures up to 40 °C and verify alignment with CCW/CW drive systems to minimize misalignment and bearing wear, particularly with the 6314-2Z bearings.

IE1 efficiency with Full Load at 94% and Partial Load values around 93.3% (75%) and 92% (50%) reduces energy consumption during typical production cycles, lowering operating costs over the motor’s life. IP23 protection helps safeguard internal components from solid objects and moisture in standard plant environments, improving reliability in conveyors and packaging lines where dust and humidity are common.

Yes. The motor is specified for S9 duty (continuous operation with intermittent peak loads) and is designed to operate in ambient temperatures up to 40 °C, with altitude considerations up to 1000 m. The aluminum frame and robust bearing package support sustained loads during prolonged starts and stops typical of heavy-duty packaging, extrusion, and conveyor processes.

The unit is manufactured in Finland (FI) with a declared customs tariff number 85015381, providing traceability for import documentation and compliance reviews. For buyers requiring regulatory alignment, this origin information aids supplier qualification, tariff planning, and adherence to regional sourcing policies while ensuring compatibility with ABB drive ecosystems.

Minimum order quantity is 1 piece, with a no make-to-order policy noted in the data. This simplifies planning for low-volume or spares stocking. When available, ABB motor lead times typically align with standard batch produce cycles, and the 180 frame size plus 4-pole configuration supports straightforward replacement in existing installations without major harness or coupling changes.