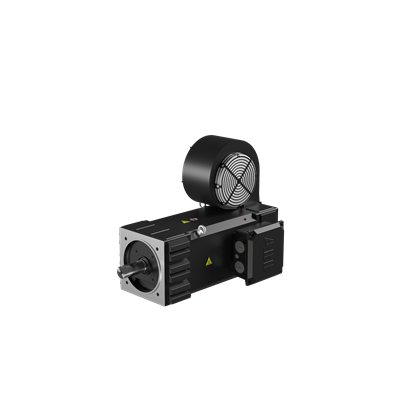

ABB 3GFT182732-SDB High Dynamic Motors - IP23

Part Number: 3GFT182732-SDB

Quick Summary

ABB 3GFT182732-SDB high dynamic performance motors are engineered for demanding industrial drives, such as conveyors and packaging lines. These motors deliver rapid torque response and consistent speed control essential for precise throughput. A common pain point is overheating and energy waste under heavy loads, which this design mitigates through robust insulation and efficient performance. The M3FT family builds on IP23 protection, IC LH insulation, and broadly compatible IEC-based standards to ensure safe operation in challenging environments. With a 380 V supply and 50 Hz operation, these motors integrate with standard plant power systems while meeting uptime targets. This combination supports lower total cost of ownership and easier procurement for automation projects.

Product Information

ABB Type Designation

M3FT 180C 4

Invoice Description

M3FT 180C 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI) | China (CN)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

380 V

Operating Frequency (fsw)

50.900 Hz

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 92.5 % | Partial Load (75%) 92.8 % | Partial Load (50%) 92.3 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.1 % | Partial Load (75%) 93.4 % | Partial Load (50%) 92.9 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

180

Bearing

6314/C3

Bearing NDE

6314/C3 VL0241

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

490 kg

Gross Weight

500 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: High dynamic torque response enables rapid acceleration and precise speed control. Business Impact: This reduces cycle times on conveyors and packaging lines while maintaining tight process tolerances. Application: Ideal for bottleneck applications in automated material handling where timing is critical and process variability is high. Feature: Energy-efficient operation at full load across 50 Hz and 60 Hz. Business Impact: Lower energy consumption and reduced operating costs over the motor’s life. Application: Suitable for continuous-duty S9 operations in fans, pumps, and other plant machinery. Feature: Aluminum frame and 6314/C3 bearings provide a strong yet lighter construction. Business Impact: Improved heat dissipation, lower mounting stresses, and extended bearing life. Application: Favorable for installations where weight and vibration management matter, such as robotic arms and heavy conveyors. Feature: IP23 protection and IC LH insulation offer reliable protection in typical factory environments. Business Impact: Enhanced uptime and reduced risk of electrical faults in dusty or humid locations. Application: Well-suited for general plant floors and outdoor-adjacent installations with moderate exposure. Feature: Terminator box location N-End right side and compatible mounting options simplify installation. Business Impact: Faster commissioning, fewer field modifications, and straightforward integration with ABB drives for tuned performance. Application: Ideal for retrofit projects and new lines with standard IEC power distribution.

Get a Quick Quote for a ABB 3GFT182732-SDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT182732-SDB?

Enquire Now

FAQs

Begin by confirming a 380 V supply and a four-pole configuration suitable for 50/60 Hz. Mount on the 180 frame, connect the terminator box at the N-End right side, and align with the driven equipment using standard couplings. Use a qualified VFD or soft starter to manage inrush and to protect the IC LH insulation during commissioning.

At 50 Hz, full-load efficiency is typically around 92.5–92.8%, with peak efficiency slightly higher at 60 Hz—about 93.1–93.4%. The four-pole design provides solid torque and stable speed control under S9 duty. Ensure correct drive settings and apply appropriate cooling to maintain reliability.

Yes. The motor's high dynamic response, four-pole configuration, and IP23 protection are well-suited for conveyors and packaging lines that require fast start-stop, precise positioning, and durable operation in factory environments. Pair with ABB drives for tuned control and energy savings. Its aluminum frame reduces installation weight, and the 6314/C3 bearing supports long life in high-cycle applications.

IP23 enclosure rating protects the motor in typical plant environments, while IC LH insulation supports safe operation at elevated temperatures. The IMB35 IM2001 frame class and 4-pole design meet common industrial standards for general-purpose automation equipment. Verify additional regional certifications (CE/UL) as required by your facility to ensure full regulatory compliance.

Energy efficiency at full load reduces operating costs, while robust bearings and engineering margins minimize downtime. Routine maintenance involves standard motor care: inspect alignment, check bearing play (6314/C3), and monitor cooling. By integrating with ABB drives, you can optimize torque curves and drive downtime, enhancing return on investment over the motor’s long service life.