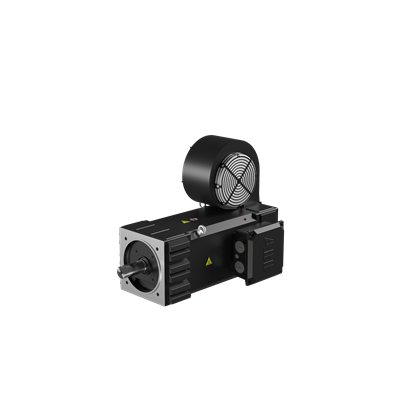

ABB M3FT180C 4 High Dynamic Motors - IP23 IE1 IC LH

Part Number: 3GFT182734-SDB

Quick Summary

ABB M3FT180C 4 High Dynamic Motors deliver precise, high-torque performance for demanding automation on conveyors and packaging lines. End users often face startup surges and energy waste; these motors address reliability, efficiency, and lifecycle costs. With IP23 protection, IC LH insulation, and IE1 efficiency data across 50 and 60 Hz, you gain compliant, predictable performance. Beyond this, the aluminum frame, robust bearings, and compact 180 mm footprint deliver installation efficiency and reduced maintenance, supporting your automation ROI. Choose M3FT for consistent torque in S9 duty and versatile mounting to fit standard frames. This combination supports production uptime, energy savings, and easier supplier qualification for global manufacturing programs. Whether upgrading existing lines or integrating new automation, ABB M3FT180C4 aligns with standards while simplifying procurement and maintenance workflows.

Product Information

ABB Type Designation

M3FT 180C 4

Invoice Description

M3FT 180C 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI) | China (CN)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

365 V

Operating Frequency (fsw)

67.500 Hz

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 93.5 % | Partial Load (75%) 93.3 % | Partial Load (50%) 92.6 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.8 % | Partial Load (75%) 93.7 % | Partial Load (50%) 92.7 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

180

Bearing

6314/C3

Bearing NDE

6314/C3 VL0241

IM Class

IMB35 IM2001

Terminator Box Location

N-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

490 kg

Gross Weight

500 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: High dynamic performance with a 4-pole design and aluminum frame enables rapid acceleration and precise torque delivery. Business Impact: This translates to shorter cycle times and higher line throughput on automation tasks such as packaging lines and conveyors. Application: Ideal for automated assembly, sorting systems, and material handling where quick torque response is critical. Feature: IP23 enclosure and IC LH insulation enhance durability in workshop environments with moderate exposure to dust and moisture. Business Impact: Results in reduced maintenance intervals and higher equipment uptime. Application: General manufacturing lines, retrofits, and equipment housed in typical plant environments. Feature: IE1 efficiency data at 50 and 60 Hz demonstrates energy savings at light and full loads. Business Impact: Lower energy costs and improved total cost of ownership for continuous operation. Application: Conveyors, filling lines, and packaging systems with variable loads. Feature: Aluminum frame and 180 mm frame size provide weight reduction and efficient heat dissipation. Business Impact: Easier handling during installation, faster commissioning, and longer bearing life under duty cycles. Application: Space-constrained machine rooms and retrofit projects where mounting compatibility matters. Feature: Robust mechanicals including 6314/C3 bearings, IMB35 IM2001 class, and N-End termination box location facilitate reliable operation and straightforward wiring. Business Impact: Lower maintenance needs, smoother servicing, and dependable life in demanding lines. Application: Industrial automation platforms requiring durable rotating assemblies and easy integration.

Get a Quick Quote for a ABB 3GFT182734-SDB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT182734-SDB?

Enquire Now

FAQs

The M3FT180C 4 uses a compact 180 frame with aluminum construction and IMB35 IM2001 mounting compatibility. The Terminator Box is located on the N-End right side, which simplifies wiring harness routing in space-constrained installations. With a 4-pole design and solid bearing support (6314/C3), it integrates smoothly with standard base plates and compliant drives on packaging and conveyance lines.

At 50 Hz full-load, IE1 efficiency is about 93.5% (partial-load down to 92.6%), while at 60 Hz full-load reaches about 93.8% (partial-load down to 92.7%). The 365 V operating voltage and 67.5 Hz nominal frequency support consistent torque across variable speeds. This translates to meaningful energy savings on long-run conveyor and packaging cycles with reduced heat generation.

Yes. The motor carries IP23 protection, which guards against solid objects greater than 12.5 mm and vertically dripping water. Coupled with IC LH insulation and IE1 efficiency, this is well-suited for typical factory floors, assembly cells, and packaging lines where moderate exposure to dust and moisture occurs, ensuring reliability without specialized enclosures.

S9 duty indicates intermittent periodic operation with substantial rest periods, suitable for applications like conveyors and packaging lines where load is applied in bursts rather than continuous operation. The ABB M3FT180C 4 is designed to handle these duty cycles reliably, supported by a robust aluminum frame and high-dynamic torque capability for quick start/stop sequences.

Total cost of ownership benefits from IE1 energy efficiency, reduced startup currents, and lower maintenance due to an aluminum frame and durable bearings (6314/C3). The motor’s location options and terminating box orientation simplify installation, lowering commissioning costs. Long-term, these factors contribute to lower energy bills, reduced downtime, and fewer spares required for lifecycle management.