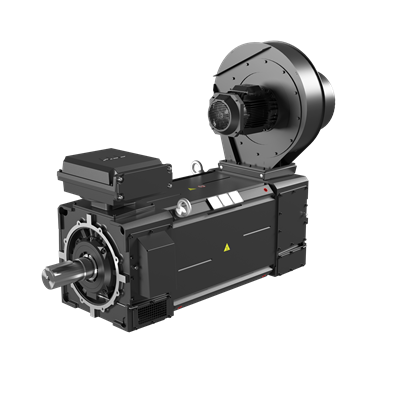

ABB 3GFT312711-APB High dynamic performance motors - IP23

Part Number: 3GFT312711-APB

Quick Summary

ABB 3GFT312711-APB high dynamic performance motors deliver robust torque and reliable operation for demanding industrial drives. Engineers often confront integration challenges such as matching voltage levels, mounting compatibility, and ambient temperature limits with existing systems. Key standards including IP23 protection, insulation class ICLH, and IMB3 IM1001 mounting enable safe, compliant operation in harsh factory environments. With a 430 V operational voltage, a 315 frame, and S9 duty, these motors help minimize downtime while boosting energy efficiency and total cost of ownership for heavy-duty applications like conveyors, pumps, and machine tools.

Product Information

ABB Type Designation

M3FT 315A 4

Invoice Description

M3FT 315A 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015394

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

430 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 93.7 % | Partial Load (75%) 94.7 % | Partial Load (50%) 95.4 %

IE Class Data (60 Hz)

IE Class NA | Full Load (100%) 93.7 % | Partial Load (75%) 94.7 % | Partial Load (50%) 95.4 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

P

Frame Material

Welded Steel

Frame Size

315

Bearing

6326M/C3

Bearing NDE

6322/C3VL0241

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

2100 kg

Gross Weight

2120 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: High dynamic performance design enables rapid torque response. Business Impact: Improves line throughput and dynamic control reducing cycle times in automated processes. Application: Suitable for packaging and material handling where precise motor response is critical. Feature: IP23 protection class and rugged welded steel frame. Business Impact: Enhances reliability in dusty or mildly damp environments, lowering maintenance costs and unplanned downtime. Application: Surface-mounted or enclosed drive systems in plants with moderate exposure to particulates. Feature: Insulation Class ICLH and robust bearing arrangement (6326M/C3). Business Impact: Supports higher operating temperatures and long service life under continuous load, decreasing replacement cycles. Application: High-temperature manufacturing lines and continuous-duty drives. Feature: 4-pole configuration with a 315 frame and weight capacity of around 2.1 metric tons. Business Impact: Delivers stable rotor dynamics for steady operation and easier installation alignment. Application: Heavy machinery like extruders and compressors where frame rigidity matters. Feature: Altitude tolerance to 1000 m and ambient temperature up to 40 °C. Business Impact: Reduces derating requirements and simplifies site selection for multi-site deployments. Application: Global manufacturing networks with varying elevation and climate. Feature: Single-speed S9 duty with 430 V supply and IP23 protection. Business Impact: Streamlines procurement, supports standard drive systems, and minimizes wiring complexity. Application: General purpose heavy-duty drives and legacy ABB-compatible systems.

Get a Quick Quote for a ABB 3GFT312711-APB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT312711-APB?

Enquire Now

FAQs

Begin with confirming the 315 frame and weight class (around 2100 kg). Align the motor shaft with the driven equipment, secure the welded steel frame to a rigid base, and connect to a compatible 430 V drive. Verify IP23 protection and install the terminator box at the D-End top. Check bearing specification 6326M/C3 and IMB3 IM1001 mounting for correct orientation and longevity.

Electrical: 430 V operation, 4 poles, IP23, insulation class ICLH, duty S9, frame 315, single-speed, 315 mm frame width. Mechanical: welded steel frame, bearing 6326M/C3 with NDE bearing 6322/C3VL0241, 2100 kg net weight and 2120 kg gross weight. It supports both rotation directions and is designed for up to 1000 m altitude and 40 °C ambient temperature.

Yes. The M3FT 315A 4 design emphasizes high dynamic performance with precise torque response. It operates under S9 duty, at 430 V, with a 4-pole configuration. Its IE class data indicates efficiency around 93.7% at full load, which helps sustain throughput while reducing energy costs in fast-moving, continuous-line applications.

Key standards include IP23 protection for environmental ingress, insulation class ICLH for high-temperature operation, and IMB3 IM1001 mounting compatibility. The design also supports ABB’s typical drive ecosystems and aligns with common industrial safety expectations for heavy-duty motors used in demanding facilities.

Expect extended service life from the welded steel frame and robust bearings (6326M/C3) plus reliable operation under 430 V and 315 frame conditions. Energy savings come from high full-load efficiency (~93.7%), reducing running costs. Planned maintenance includes bearing inspections, alignment checks, and ensuring proper ventilation to maintain ambient conditions around 40 °C.