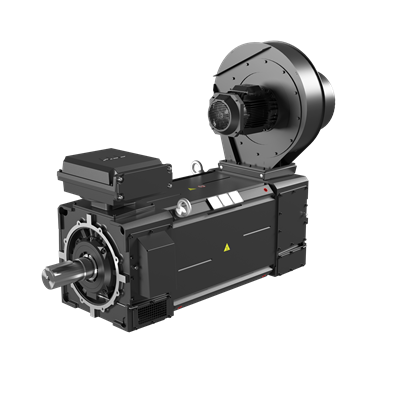

ABB 3GFT312712-ADB Motors & Drives - IP23

Part Number: 3GFT312712-ADB

Quick Summary

ABB 3GFT312712-ADB motors deliver high dynamic performance for demanding industrial drive systems, enabling rapid acceleration and precise speed control in conveyors, pumps, and processing equipment. Engineers often contend with downtime, energy waste, and compatibility gaps when upgrading legacy machines; this model addresses those challenges with a robust frame and proven ABB design. The motor carries critical certifications and ratings that support reliable operation in production environments: IP23 protection for moderate dust and moisture, IE2 efficiency for reduced energy usage, and IC LH insulation for sustained performance in demanding duty cycles. When paired with standard VFDs and existing control architectures, it delivers predictable, scalable performance, helping you meet production targets while controlling total cost of ownership.

Product Information

ABB Type Designation

M3FT 315A 4

Invoice Description

M3FT 315A 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI) | China (CN)

Customs Tariff Number

85015394

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

370 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 95.3 % | Partial Load (75%) 96.2 % | Partial Load (50%) 96.7 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Welded Steel

Frame Size

315

Bearing

6326M/C3

Bearing NDE

6322/C3VL0241

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

2100 kg

Gross Weight

2120 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

High dynamic performance motor design enables fast torque response and smooth operation under peak loads, directly improving line throughput and reducing cycle times in conveyors and pump drives. By combining a 4-pole configuration with a 370 V supply, the solution delivers consistent torque across a wide operating envelope, supporting reliable operation in manufacturing lines and processing equipment. IP23 protection and IC LH insulation enhance reliability in moderate dust and moisture environments typical of factory floors, decreasing unplanned downtime and maintenance costs. IE2 efficiency reduces energy consumption across full-load and part-load conditions, driving lower operating expenses and supporting sustainability goals. The motor is VFD-ready and designed for easy integration with standard automation architectures, simplifying installation and allowing rapid project ramp-ups. The 315 frame, robust welded steel construction, and precision bearings (6326M/C3 and 6322/C3VL0241) provide long service life in demanding applications such as conveyors, mixers, and fans, while maintaining quiet, cool operation. With a country of origin listing (Finland and China) and clear tariff coding, procurement and compliance become straightforward, enabling faster sourcing and reduced risk for global projects. This combination of mechanical strength, electrical robustness, and industry-aligned design makes it a practical choice for engineering teams seeking reliability, efficiency, and lifecycle value in industrial automation environments.

Get a Quick Quote for a ABB 3GFT312712-ADB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT312712-ADB?

Enquire Now

FAQs

The 3GFT312712-ADB is designed as a VFD-ready, 4-pole, 315-frame motor compatible with standard industrial drives. Begin with verifying 370 V supply, confirm screen-and-shielded cable routing, and use a compliant motor starter and drive ramp settings. Take advantage of ABB or equivalent documentation for wiring diagrams, fieldbus integration, and thermal monitoring. Ensure motor orientation and coupling align with the drive’s torque profile to maximize efficiency and life. Grounding and bonding should follow your plant’s electrical safety standards, and a soft-start or pre-charge sequence is recommended to minimize inrush and mechanical stress.

This motor operates at a 4-pole configuration with a 370 V nominal voltage, IP23 protection, and IE2 efficiency. It supports S9 duty (continuous with occasional overload) and is designed for high dynamic response. Frame size is 315, with a net weight around 2,100 kg, suitable for heavy-load conveyors, pumps, and processing equipment. The combination of 315 frame, IE2 efficiency, and robust bearings (6326M/C3 and 6322/C3VL0241) ensures reliable performance under peak loads and variable speeds when driven by a compatible inverter.

Yes. The 315-frame, 4-pole design delivers strong starting torque and rapid acceleration, which are essential for conveyors with frequent starts/stops and variable loads. The IE2 efficiency improves energy performance under mixed speed profiles, while IP23 protection guards against dust and moisture typically encountered on factory floors. For best results, pair with an appropriate VFD or soft-start strategy and ensure control parameters (acceleration, deceleration, torque limits) are tuned to the conveyor profile and duty cycle.

The motor features IP23 protection, IC LH insulation, and IE2 efficiency, with design considerations for 1000 m altitude and 40 °C ambient temperature. These certifications support safe operation in mid-range environments, align with international standards for industrial motors, and help satisfy regulatory and customer requirements for energy efficiency and equipment resilience. The unit also carries a defined impedance and duty class (S9), ensuring predictable performance in continuous operation with occasional overload scenarios. These attributes simplify procurement, qualification testing, and installation in regulated facilities.

The IE2 efficiency rating reduces energy consumption over the motor’s life, contributing to lower utility costs and a shorter payback period in systems with frequent starts or high duty cycles. The robust 315 frame, welded steel construction, and high-grade bearings support long service intervals and reduced maintenance investments. While maintenance will still include periodic bearing checks, alignment verification, and inverter health monitoring, the motor is designed to minimize downtime through reliable operation in demanding industrial environments. For ROI calculation, factor energy savings, reduced maintenance, and the cost of spare parts against the initial purchase price and installation costs.