ABB 3GFT312713-AUB High dynamic performance motors - IE3 efficiency

Part Number: 3GFT312720-ADB

Quick Summary

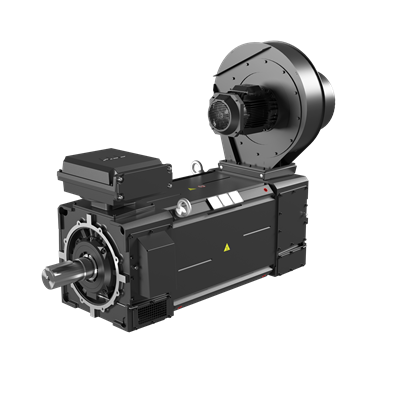

ABB 3GFT312713-AUB high dynamic performance motors deliver reliable motion control for demanding industrial drives and heavy-duty applications. Engineers often face the challenge of balancing efficiency, maintenance intervals, and thermal management in large motors. This motor family prioritizes energy savings through IE3 efficiency and rugged IP23 protection with robust ICLH insulation, ensuring dependable operation across harsh environments. For manufacturing floors, that translates into lower energy costs, reduced downtime, and easier compliance with safety and performance standards. In short, these motors align with ABB's M3FT strategy to boost automation reliability while supporting scalable, cost-effective upgrades in modern facilities.

Product Information

ABB Type Designation

M3FT 315B 4

Invoice Description

M3FT 315B 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI) | China (CN)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

370 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 90.2 % | Partial Load (75%) 92.2 % | Partial Load (50%) 93.8 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Welded Steel

Frame Size

315

Bearing

6326M/C3

Bearing NDE

6322/C3VL0241

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

2350 kg

Gross Weight

2370 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

IE3 efficiency class paired with a 640 V operating voltage reduces energy consumption across full-load operation. This delivers lower operating costs, improved thermal margins, and compliance with efficiency regulations, especially on continuous S9 duty lines. Applications include conveyors, pumps, and fans in automated manufacturing lines where sustained high-efficiency performance matters. IP23 protection combined with ICLH insulation protects windings from dust and moisture, extending service life and reducing unscheduled downtime, making them suitable for outdoor or semi-enclosed installations and safer maintenance windows. In material handling, process lines, and packaging equipment, this translates to fewer outages and steadier production. The 315 frame in welded steel offers rugged mechanical integrity; coupled with bearings 6326M/C3 and 6322/C3VL0241, it provides vibration resilience and longer bearing life for heavy-duty use. This reduces maintenance costs in mills, presses, and conveyors. A single-speed, 4-pole design supports predictable torque during continuous operation (S9), while the bilateral rotation capability and top D-End terminator box simplify wiring and retrofits with standard ABB drive systems. For project planning, the motor’s 2100 kg net weight and 2120 kg gross weight inform crane and base requirements, and the 1-piece minimum order helps streamline procurement for large-scale automation programs while aligning with the M3FT family for scalable investments.

Get a Quick Quote for a ABB 3GFT312720-ADB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT312720-ADB?

Enquire Now

FAQs

Plan for a 315 frame mounted in welded steel, with D-End top terminal box access options to simplify wiring. Allow for a crane-capable installation due to a 2100 kg net weight. Ensure operation at up to 1000 m altitude and 40 °C ambient to preserve efficiency and bearing life. The motor supports bilateral rotation for versatile layouts and integration with standard ABB drives.

IE3 efficiency delivers higher energy savings across full-load and partial-load conditions characteristic of S9 duty. In 50/60 Hz operation, you can expect near-full-load efficiency around 95.6% with reduced heat generation. This supports lower energy costs, improved thermal management, and extended motor life in continuous operation like conveyors and pumps within automated lines.

Yes. The M3FT family is designed for high dynamic performance, providing rapid torque response and reliable startup for conveyors, pumps, and fans. The 4-pole, 640 V design delivers robust torque at low speeds and steady performance under load fluctuations, while IP23 and ICLH insulation protect reliability in demanding industrial environments.

The motor features IP23 protection and ICLH insulation, offering dust and moisture resistance along with durable winding insulation. This combination reduces insulation failures, extends service life, and minimizes maintenance disruptions in factories with exposure to contaminants or variable temperatures.

With rugged bearings (6326M/C3 and 6322/C3VL0241), a solid welded-steel frame, and a heavy 315-class footprint, maintenance intervals extend due to improved durability and lower vibration. The IE3 efficiency and single-speed design support a lower total cost of ownership through energy savings and reduced downtime, making this motor a sound long-term investment for automation projects.