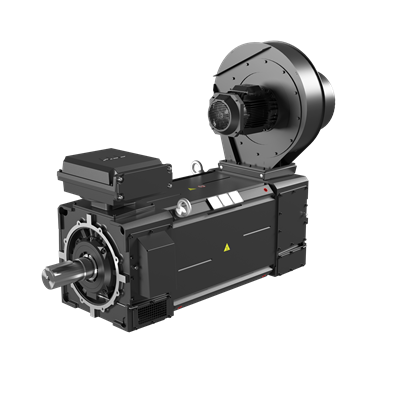

ABB M3FT 315B 4 High dynamic performance motors - IP23

Part Number: 3GFT312721-AUB

Quick Summary

ABB M3FT 315B 4 high dynamic performance motors deliver precise, energy-efficient motion control for heavy-duty conveyors and machine tools. One common challenge is downtime caused by torque fluctuations and thermal stress in continuous operation. Key certifications support reliability, including IP23 ingress protection, IC LH insulation, and IE1 efficiency at variable loads. With four poles, it provides stable torque and smooth acceleration, and is compatible with standard 640 V drive architectures such as VFDs and soft starters in automation lines. This combination helps manufacturers reduce energy costs, improve uptime, and maintain consistent performance across global production facilities. Coupled with robust mechanical design and temperature tolerance up to 40 °C ambient and 1000 m altitude, this motor is a dependable choice for harsh environments.

Product Information

ABB Type Designation

M3FT 315B 4

Invoice Description

M3FT 315B 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI) | China (CN)

Customs Tariff Number

85015394

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

640 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class IE1 | Full Load (100%) 94.0 % | Partial Load (75%) 94.9 % | Partial Load (50%) 95.6 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

U

Frame Material

Welded Steel

Frame Size

315

Bearing

6326M/C3

Bearing NDE

6322/C3VL0241

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

2350 kg

Gross Weight

2370 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: High dynamic performance motor delivers rapid acceleration and precise torque regulation thanks to a four-pole design in the 315 frame. This configuration supports tight process control and shorter cycle times in high-speed packaging, metalworking, and material-handling lines. The 640 V operation and IP23-rated enclosure ensure compatibility with common factory power systems while maintaining reliable performance across variable loads. Business Impact: Higher throughput and tighter process accuracy reduce scrap and rework, driving observable improvements in overall equipment effectiveness (OEE). Application: Ideal for conveyors, presses, and machine tools under S9 duty in automation lines. Feature: Durable mechanical construction uses a welded steel frame and IMB3 IM1001 mounting class for robust alignment in challenging environments. Ball bearings 6326M/C3 with NDE 6322/C3VL0241 provide long service life and stable rotary behavior under heavy loads. Terminator box location at D-End top simplifies wiring and service access, reducing installation time and commissioning risk. Business Impact: Fewer unplanned outages and lower maintenance cycles. Application: Heavy industrial lines, machining centers, and material handling stations. Feature: Electrical performance and protection features include IE1 efficiency data for full and partial loads (94.0–95.6%), IP23 ingress protection, and insulation class ICLH for high-temperature endurance. The motor supports operation up to 1000 m altitude and 40 °C ambient, ensuring dependable operation in many global sites. Voltage code U and 640 V operation align with standard industrial drives, enabling straightforward integration with VFDs. Business Impact: Energy savings over lifetime and reduced cooling requirements. Application: Global manufacturing facilities with variable ambient conditions. Feature: Compatibility and installation advantages include single piece MOQ (1 piece) and country of origin Finland/China, offering flexible supply options for global manufacturing. The Product Type designation 3FTB__M3FT__HDP__IP23_ confirms integration with ABB's HDP line and documented compatibility with common ABB and third-party controls. The motor's weight (net 2350 kg; gross 2370 kg) reflects a sturdy, durable product ready for heavy use in production. Business Impact: Faster procurement cycles and predictable lead times. Application: New installations and plant modernization programs. Feature: Field performance and ROI considerations show reliable torque behavior, consistent efficiency across loads, and a robust design that supports long intervals between service events. Practical insights indicate energy savings from IE1 performance combined with high reliability, translating into meaningful ROI for networks of facilities seeking uptime improvements and energy cost reductions.

Get a Quick Quote for a ABB 3GFT312721-AUB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT312721-AUB?

Enquire Now

FAQs

Plan for a D-End top terminator box, use the 315 frame mounting (IMB3 IM1001), and ensure alignment with the shaft and bearing clearances. Connect to a standard 640 V drive or VFD, check ambient conditions up to 40 °C and altitude up to 1000 m, and confirm the IP23 enclosure suitability for the intended environment. Proper cable routing and torque settings will minimize vibration and extend bearing life.

At 50 Hz, the motor delivers full-load efficiency around 94.0%, with partial-load values of 94.9% at 75% and 95.6% at 50%. This steady efficiency translates to lower electrical losses during frequent starts, contributing to reduced cooling loads and improved energy cost management over the motor’s lifecycle.

Yes. The motor carries IP23 ingress protection, suitable for indoor industrial environments with moderate exposure to dust and moisture. Its insulation class ICLH and IE1 efficiency support reliable operation across diverse global sites. The 640 V operation and 1000 m altitude tolerance further enable use in plants with varying electrical setups and ambient conditions.

Key certifications include IP23 protection, IE1 efficiency data for both full and partial loads, and insulation class ICLH. The design also features IMB3 IM1001 mounting class, and bearing arrangements 6326M/C3 with NDE 6322/C3VL0241, all of which support compliance with common industrial standards and reliable long-term operation on S9 duty.

The combination of IE1 energy efficiency, reduced downtime due to stable torque and robust bearings, and compatibility with standard drives can yield noticeable energy savings and uptime improvements. A corollary benefit is predictable maintenance schedules thanks to a robust, welded steel frame and reliable IM class, supporting a favorable total cost of ownership over the motor’s service life.