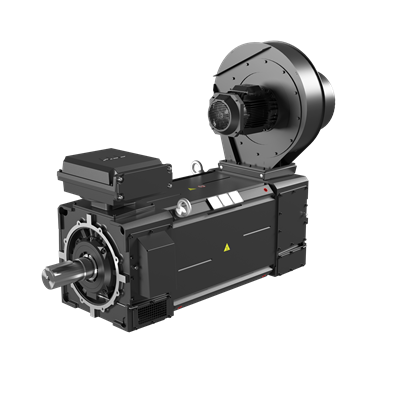

ABB 3GFT312723-AUB 3FTB M3FT HDP High Dynamic Motor - IP23

Part Number: 3GFT312723-AUB

Quick Summary

ABB 3GFT312723-AUB high dynamic performance motor delivers reliable power for heavy-duty drives such as pumps, fans, and conveyors. Many automation lines suffer energy waste and unplanned downtime when motors don’t match load profiles or environmental conditions. This design offers IP23 protection, IE3 efficiency, and IC LH insulation to sustain performance in tough factory floors and hot environments. Designed for easy integration with ABB drives and common control architectures, it reduces commissioning time and simplifies spare-parts planning. By optimizing efficiency and maintenance intervals, this motor lowers operating costs while boosting overall line productivity.

Product Information

ABB Type Designation

M3FT 315B 4

Invoice Description

M3FT 315B 4

Product Name

High dynamic performance motors

Product Type

3FTB__M3FT__HDP__IP23_

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI) | China (CN)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Motor Operational Voltage

640 V

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC06

IE Class Data (50 Hz)

IE Class IE3 | Full Load (100%) 96.1 % | Partial Load (75%) 96.6 % | Partial Load (50%) 96.9 %

IE Class Data (60 Hz)

IE Class IE3 | Full Load (100%) 96.1 % | Partial Load (75%) 96.6 % | Partial Load (50%) 96.9 %

IP Class

IP23

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

U

Frame Material

Welded Steel

Frame Size

315

Bearing

6326M/C3

Bearing NDE

6322/C3VL0241

IM Class

IMB3 IM1001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

2350 kg

Gross Weight

2370 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: High dynamic performance motor design enables rapid torque response and precise speed control. Business Impact: Improves process control, reduces cycle times, and enhances system throughput for demanding production lines. Application: Suitable for pumps and conveyors in packaging, plastics, and chemical processing where load transients are common. Feature: 640 V operating voltage and four-pole configuration deliver robust torque at steady state. Business Impact: Lets designers choose compact drives without oversized power electronics, cutting cabinet space and cooling needs. Application: Industrial automation and material handling with high starting torque requirements. Feature: IP23 enclosure and IC LH insulation provide reliability in standard factories and elevated ambient temperatures. Business Impact: Increases uptime and safety while limiting insulation-related failures. Application: Motors mounted in open or semi-enclosed environments with moderate dust and humidity. Feature: IMB3 IM1001 mounting class and welded steel frame ensure stiff, vibration-resistant construction. Business Impact: Extends bearing life and reduces maintenance costs in continuous operation. Application: Heavy-duty process lines with long runtimes. Feature: 315 frame with robust bearings (6326M/C3, 6322/C3VL0241) and S9 duty rating. Business Impact: Delivers predictable performance under demanding loads and helps maintain efficiency. Application: Mining, metals, and water/wastewater equipment requiring reliable, long-life motors. Feature: Direction of rotation on both sides enables flexible installation. Business Impact: Simplifies retrofits and field wiring, reducing installation risk. Application: Retrofit projects and new builds where space and wiring constraints vary. Feature: Country of Origin mix (Finland/China) and customs tariff 85015399. Business Impact: Clear supply chain and compliance with international trade requirements. Application: Global procurement programs needing transparent sourcing.

Get a Quick Quote for a ABB 3GFT312723-AUB

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GFT312723-AUB?

Enquire Now

FAQs

Ensure frame size is compatible with the 315 frame and the mounting configuration aligns with IMB3 IM1001 standards. Verify 640 V three-phase supply and IP23 enclosure for your environment. Check the D-End top terminator box location and confirm a suitable space for robust belt- or gear-driven loads. This alignment minimizes rework during retrofit and accelerates commissioning.

IE3 class indicates significantly improved energy efficiency at nominal and part-load conditions. With full-load efficiency around 96% and strong performance at partial loads (approx. 96.6% at 75% and 96.9% at 50%), annual energy costs for pumps, fans, or conveyors can be substantially lower compared with IE2 motors. The result is meaningful lifecycle savings and reduced heat in cabinets.

Yes. The S9 duty rating means the motor is designed for heavy, intermittent loads with high torque, making it well-suited for pumps and conveyors that experience load peaks. Its four-pole design, IP23 enclosure, and robust bearings help maintain performance during start-stop cycles, while the 315 frame supports stable mounting on typical equipment frames.

The motor features IP23 ingress protection and IC LH insulation for reliable operation in typical plant environments. It adheres to IE3 energy efficiency standards and IMB3 IM1001 mounting classifications, while the 85015399 tariff code supports customs and cross-border procurement. Although SIL and CE markings aren’t listed in the spec, the combination of IP rating and efficiency aligns with common regulatory expectations for industrial equipment.

Expect longer bearing life from the 6326M/C3 and 6322/C3VL0241 bearings and reduced maintenance through robust welded steel framing. The motor’s efficiency and reliability translate to lower energy costs and less downtime. ROI improves when paired with ECM drives and proper lubrication schedules, allowing you to optimize run-time, energy use, and spare-parts planning over the motor’s service life.