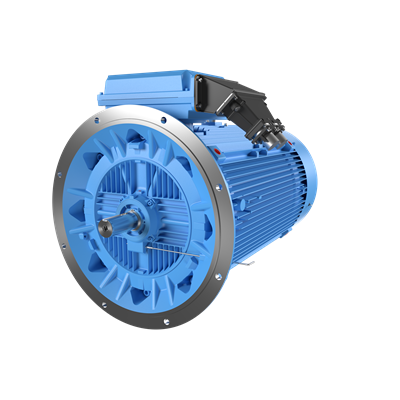

ABB 3GGP402520-BEK 3-Phase Motor - IE3 IP55 Dust Ignition

Part Number: 3GGP402520-BEK

Quick Summary

ABB 3GGP402520-BEK 3-Phase motor delivers reliable torque for dust-ignition risk environments in heavy industry. In challenging facilities, dust exposure can drive frequent maintenance and energy inefficiency, hurting uptime and total cost of ownership. It features IP55 enclosure, IE3 efficiency, and ICFL insulation suitable for demanding atmospheres, plus explosion-protection considerations like gas-group IIC potential environments. The 4-pole, 630 kW design with IMB5 mounting and 500 V supply aligns with standard drives and installation practices, minimizing retrofit work. This motor is a strong candidate for customers seeking compliant, durable, and energy-efficient solutions in mining, chemical processing, and bulk material handling. For reliability teams, serviceability and spare-part availability are clear advantages.

Product Information

ABB Type Designation

M3GP 400LB 4

Product Name

3-Phase squirrel cage motor

Product Type

3GP3__M3GP_IE3_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015394

Medium Description

630kW, 4 Poles, Frame Size 400, 3 Phases, 500V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GGP402520-BEK)

Short Description

630kW, 4P, Frame Size 400, 3PH, 500V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T3

Input Voltage (Uin)

500 V

Frequency (f)

50 Hz

Output Power

630 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE3 | Full Load (100%) 96.0 % | Partial Load (75%) 96.0 % | Partial Load (50%) 95.2 %

IE Class Data (60 Hz)

IE Class IE3 | Full Load (100%) 96.2 % | Partial Load (75%) 96.0 % | Partial Load (50%) 95.3 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S1

Voltage Code

E

EX-Protection

Exec

Gas Group

IIC

Frame Material

Cast Iron

Frame Size

400

Bearing

6324/C3

Bearing NDE

6319/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1891 mm

Product Net Height

1045 mm

Product Net Width

840 mm

Product Net Weight

3300 kg

Gross Weight

3340 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature → Business Impact → Application: Dust-ignition proof design with IP55 enclosure reduces the risk of ignition in dusty environments, delivering safer operation and lower regulatory downtime, especially in mining and chemical processing. This directly lowers total cost of ownership while enabling continuous operation in adverse atmospheres. Feature → Business Impact → Application: IE3 efficiency at 50 Hz and 60 Hz delivers measurable energy savings on heavy-duty conveyors and pumps, improving utility metrics without sacrificing performance in high-load conditions. Feature → Business Impact → Application: ICFL insulation with robust cast-iron frame and IMB5/IM3001 mounting provides long bearing life and straightforward installation, reducing maintenance intervals and spare-part needs across bulk-material handling plants. Feature → Business Impact → Application: 600+ kW output with 4 poles and 500 V supply ensures compatibility with existing ABB drives and standard drive curves, enabling smoother retrofits and faster commissioning in new-builds or upgrades. Feature → Business Impact → Application: Gas Group IIC rating and EX-type protection support safer operation in hazardous areas, helping to meet strict regulatory standards and industry certifications across mining, petrochemicals, and wood-processing facilities. Feature → Business Impact → Application: Top terminator box location and IMB5/IM3001 mounting simplify wiring and service access, reducing indoor installation time and enabling easier serviceability during routine maintenance. Feature → Business Impact → Application: Frame Size 400 and 630 kW rating provide a proven footprint for high-torque, high-demand applications, including crushers, fans, and grinding processes, with compatibility to standard industrial gear and drive systems. Feature → Business Impact → Application: Long bearing life (6324/C3 bearing, 6319/C3 NDE) and cast-iron construction deliver rugged durability in harsh environments, supporting extended service intervals and lower lifecycle costs in cement, metal, and material-handling facilities. Feature → Business Impact → Application: 4-pole, S1 duty cycle ensures reliable operation and predictable performance in continuous operation environments, aligning with plant-wide reliability targets and maintenance planning.

Get a Quick Quote for a ABB 3GGP402520-BEK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GGP402520-BEK?

Enquire Now

FAQs

Yes. The 3GGP402520-BEK is a 4-pole, 630 kW motor designed for IMB5 IM3001 mounting and offers a Top terminator box location for easy wiring. It uses a 500 V supply, 50 Hz, and is compatible with standard ABB drives and installation practices. The frame size 400 and 4-pole design simplify retrofits in existing plant footprints.

The motor achieves IE3 efficiency values around 96% at full load for 50 Hz, with partial-load performance near 95–96%. At 60 Hz, full-load efficiency is about 96.2%, while partial-load figures remain in the mid- to high-95% range. These figures support energy savings in continuous-duty applications like conveyors and fans.

Yes. It is designed for hazardous environments with IP55 protection, ICFL insulation, and gas-group IIC capability, aligning with explosion-protection requirements. The dust-ignition-proof construction supports safe operation in mining, chemical processing, and bulk-handling facilities where dust and ignition hazards are present.

The motor features IP55 protection, IE3 efficiency, and ICFL insulation, with supporting design approvals for hazardous environments (gas-group IIC) and robust mechanicals like IMB5/IM3001 mounting. These characteristics help meet industrial safety and performance standards across regulated sectors such as mining and chemicals.

Energy savings from IE3 efficiency reduce operating costs, especially in high-duty applications. The rugged cast-iron frame, sealed IP55 enclosure, and long-life bearings limit maintenance intervals, while standard spare parts support lower downtime. This combination delivers faster payback in plants prioritizing uptime, reliability, and total-cost-of-ownership reduction.