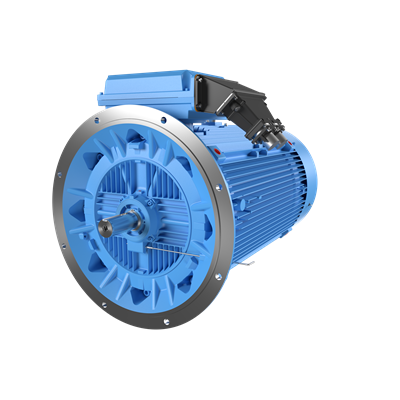

ABB 3GGP451510-BDK 3-Phase motor - Dust Ignition Proof IE3

Part Number: 3GGP451510-BDK

Quick Summary

ABB 3GGP451510-BDK is a dust-ignition-proof, IE3 800 kW, 400 V three-phase motor built for heavy industrial drives. In dusty environments, unpredictable cooling and seal wear can drive maintenance costs and unplanned downtime. It combines IP55 protection, IC411 insulation, and IMB5/IM3001 mounting to withstand harsh conditions while meeting demanding safety and reliability standards. This design supports energy-focused procurement with high-efficiency operation and robust mechanicals, delivering lower total cost of ownership in mining, processing, and material-handling facilities. Field-ready features like a top terminator box and a cast-iron frame enable straightforward installation and long service life in tough environments.

Product Information

ABB Type Designation

M3GP 450LA 2

Product Name

3-Phase squirrel cage motor

Product Type

3GP3__M3GP_IE3_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Medium Description

800kW, 2 Poles, Frame Size 450, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GGP451510-BDK)

Short Description

800kW, 2P, Frame Size 450, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T3

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Output Power

800 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE3 | Full Load (100%) 95.8 % | Partial Load (75%) 95.5 % | Partial Load (50%) 94.4 %

IE Class Data (60 Hz)

IE Class IE3 | Full Load (100%) 95.8 % | Partial Load (75%) 95.5 % | Partial Load (50%) 94.2 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Unidirectional

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exec

Gas Group

IIC

Frame Material

Cast Iron

Frame Size

450

Bearing

6317M/C3

Bearing NDE

6317M/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

2027 mm

Product Net Height

1231 mm

Product Net Width

966 mm

Product Net Weight

4000 kg

Gross Weight

4040 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

The first feature highlights energy efficiency, where IE3 performance translates to measurable energy cost reductions during continuous operation, especially on long-running conveyor and pump drives. The business impact is lower kW demand charges and improved return on investment, making it attractive for large-scale LV motor projects in mining and processing plants. Application context includes 400 V, 50 Hz utility supplies common in European facilities, with a 2-pole design enabling compact, high-torque startup while maintaining reliability in demanding loads. A second feature emphasizes dust ignition proofing and IP55 protection, which reduces the risk of ignition sources in combustible atmospheres and minimizes maintenance interruptions due to environmental contamination. This suits cement, wood, and grain handling workflows where rugged enclosure integrity is essential. A robust IMB5/IM3001 mounting option provides installation compatibility across existing frames and framesize 450 layouts, ensuring quick retrofit or new installations without costly adaptors. The third feature focuses on the cast-iron frame and bearing configuration (6317M/C3), improving vibration damping and lifecycle reliability in high-load conditions, especially at 1000 m altitude and 40 °C ambient temperatures. For operators, this means longer service intervals, easier spare-part planning, and predictable performance. A fourth feature covers the enclosure and terminal box positioning (top), simplifying wiring, cable management, and service access during periodic maintenance, reducing downtime. The design also supports compliance with IC411 insulation class and an energy-efficient duty cycle (S1) for steady-state operation in continuous processes. By combining these characteristics, ABB delivers a durable, efficient, and serviceable solution for harsh, dust-prone environments that align with maintenance budgets and safety standards.

Get a Quick Quote for a ABB 3GGP451510-BDK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GGP451510-BDK?

Enquire Now

FAQs

This model uses IMB5/IM3001 mounting and a 450 frame, which simplifies retrofits and new builds. Plan for top-access terminator box, a Cast Iron frame, and standard 400 V, 50 Hz supply. Ensure adequate clearance for cooling at 40 °C ambient and up to 1000 m altitude, and verify compatibility with existing cable routes and terminal block configurations to avoid rework.

IE3 efficiency data show Full Load efficiency around 95.8% at 100% load for both 50 Hz and 60 Hz, with 75% load near 95.5% and 50% load around 94.4% at 50 Hz, and 94.2% at 60 Hz. This translates to tangible energy savings in continuous-duty drives such as conveyors and pumps while maintaining stable torque and speed characteristics.

Yes. The motor is designed as a dust-ignition-proof unit with IP55 protection and IC411 insulation. Its rugged cast-iron frame, 2-pole design, and top-entry terminal box support reliable operation in harsh environments, meeting safety and performance requirements typical of mining, wood processing, and cement applications.

Key specifications include IP55 protection and IC411 insulation class, with EX-Protection noted as Exec and a Gas Group rating of IIC. The unit operates under S1 duty, with a temperature class T3 and voltage code D, supporting compliance in standard industrial automation settings and hazardous-area guidelines where applicable.

Energy efficiency from IE3 reduces operating costs on long-running drives, while robust protection minimizes downtime and maintenance expenses in dusty environments. Combined with dependable bearings (6317M/C3), a long service life, and straightforward installation, operators typically see shorter payback periods and lower total cost of ownership in mining, processing, and material-handling facilities.