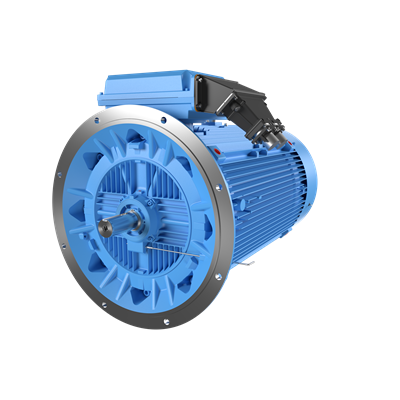

ABB 3GGP454510-BDK Motors & Drives - Dust Ignition Proof IE3

Part Number: 3GGP454510-BDK

Quick Summary

ABB 3GGP454510-BDK is a dust ignition-proof IE3 LV motor for hazardous-location process industries. Many buyers struggle to meet safety, efficiency, and uptime requirements in harsh environments. Key certifications include IP55 protection, IE3 efficiency, and Ex protection for hazardous spaces, enabling compliant operation with confidence. This design delivers robust reliability, reduced energy costs, and straightforward installation in top-entry terminal boxes, making it a practical choice for continuous-duty fans, pumps, and conveyors in demanding facilities, and easier to service. By combining durable cast-iron frame, IMB5/IM3001 mounting, and 8-pole performance, the motor supports long service life under elevated ambient temperatures and altitude up to 1000 m.

Product Information

ABB Type Designation

M3GP 450LA 8

Product Name

3-Phase squirrel cage motor

Product Type

3GP3__M3GP_IE3_CI

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015394

Medium Description

450kW, 8 Poles, Frame Size 450, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GGP454510-BDK)

Short Description

450kW, 8P, Frame Size 450, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T3

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Output Power

450 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE3 | Full Load (100%) 94.6 % | Partial Load (75%) 94.9 % | Partial Load (50%) 94.3 %

IE Class Data (60 Hz)

IE Class IE3 | Full Load (100%) 95.0 % | Partial Load (75%) 95.1 % | Partial Load (50%) 94.6 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

8

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exec

Gas Group

IIC

Frame Material

Cast Iron

Frame Size

450

Bearing

6326/C3

Bearing NDE

6322/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

2187 mm

Product Net Height

1231 mm

Product Net Width

966 mm

Product Net Weight

3750 kg

Gross Weight

3790 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Dust ignition-proof construction and Ex protection give the ABB 3GGP454510-BDK a safer footprint in hazardous environments. The EX protection (Exec) and IIC gas group classification help prevent ignition risks even in dust-laden atmospheres and high-temperature processes. This reduces regulatory complexity, minimizes the need for protective enclosures, and supports safer maintenance tasks. Combined with the durable cast-iron frame, the motor withstands harsh factory conditions and ensures reliable startup after long downtimes. It is well suited for cement plants, chemical processing facilities, and mining operations where dust and explosive hazards are present. IE3 efficiency translates to meaningful energy savings across continuous operating cycles. The motor top-line efficiency of about 94.6–95.0% at full load reduces electricity consumption and lowers cooling requirements. In real-world terms, this means lower energy bills, cooler bearing temperatures, and longer component life in conveyors, pumps, and fans operating around the clock. The robust efficiency performance also helps meet corporate sustainability goals and regulatory energy mandates. IP55 protection guards against dust ingress and water spray, enabling reliable operation on factory floors and outdoor sites. The 8-pole design and frame size 450 provide a strong torque profile while maintaining compact envelope, and the IMB5/IM3001 mounting supports quick, secure installation. The D connection configuration simplifies wiring around tight spaces, and the top-entry termination box facilitates maintenance access and safe cable routes. Overall, these features reduce installation time and on-site risk. The motor delivers 450 kW at 400 V and 50 Hz with 8 poles, balancing speed and torque for demanding drives such as belt conveyors or hydraulic pumps. It tolerates ambient temperatures up to 40 °C and operates at altitudes up to 1000 m while maintaining full-load performance and efficient cooling. The dual rotation direction provides installation flexibility in complex layouts. The D-code connection and insulated windings support reliable performance in variable electrical networks. Bearings 6326/C3 and 6322/C3, combined with IMB5 IM3001, support long service life and predictable maintenance. D wiring, top termination, and modular construction reduce installation risk and spare parts inventory. This translates to superior uptime and predictable maintenance budgets.

Get a Quick Quote for a ABB 3GGP454510-BDK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GGP454510-BDK?

Enquire Now

FAQs

To install ABB 3GGP454510-BDK in hazardous locations, select IMB5/IM3001 mounting and top-entry terminal access. Use the D connection configuration and ensure IP55 protection and Ex classification for gas IIC zones. Confirm ambient temperature up to 40°C and altitude up to 1000 m, and plan for S1 continuous duty with safe start-up in dusty environments.

At full load, IE3 efficiency for the 3GGP454510-BDK is about 94.6–95.0%, depending on supply frequency. This yields meaningful operating-cost savings compared with IE2 motors, especially in continuous-duty conveyors, pumps, and fans. The 450 kW rating at 400 V delivers strong torque with lower heat generation and improved thermal management. That translates to lower life-cycle costs in mission-critical plants.

Yes. The 450 kW, 8-pole design with 400 V and 50 Hz, IP55 enclosure, Ex protection, and IMB5/IM3001 mounting is well-suited for demanding conveyors, pumps, and fan systems in cement and mining. The D-connection configuration simplifies wiring, while the top-entry terminator box eases installation and serviceability. These features support reliable operation on challenging production lines in harsh environments.

The motor carries IP55 ingress protection, Ex protection for hazardous areas with gas group IIC, and IE3 efficiency certification. Insulation is rated ICLF and mounting aligns with IMB5/IM3001. These certifications support regulatory compliance, safer installation, and energy efficiency, reducing risk during audits in chemical, mining, and other hazardous industries.

Expect low maintenance due to robust cast-iron frame and reliable bearings (6326/C3 and 6322/C3) with IMB5 IM3001 mounting. IE3 efficiency reduces energy costs over the lifecycle, while IP55 and Ex protection minimize downtime from dust and fumes. Spare parts and standard mounting simplify service, improving return on investment in critical processes.