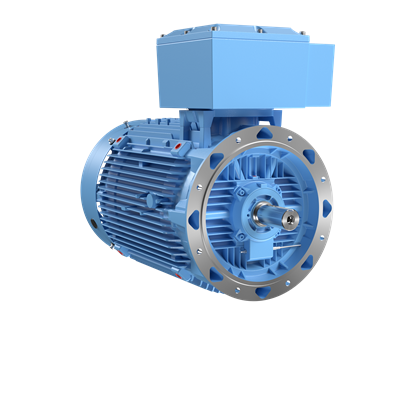

ABB 3GJM281210-AEG 3-Phase Squirrel Cage Motor - Exdb

Part Number: 3GJM281210-AEG

Quick Summary

ABB 3GJM281210-AEG is a 3-phase squirrel cage motor designed for mining and heavy industrial applications. Operators often wrestle with harsh environments, strict safety standards, and the challenge of integrating new motors with existing equipment. This model delivers IP66 protection, IE2 efficiency, and Exdb flameproof rating to support compliance and reliability. With a robust cast-iron frame and top-termination box, it reduces maintenance while simplifying installation and lowering total cost of ownership.

Product Information

ABB Type Designation

M3JM 280SMA 2

Invoice Description

M3JM 280SMA 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 94.3 % | Partial Load (75%) 93.8 % | Partial Load (50%) 92.2 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

E

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

644 kg

Gross Weight

664 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Exdb explosion protection and IP66 enclosure provide rugged reliability in hazardous environments, reducing risk and enabling use in mining and surface facilities. The 280 frame in cast-iron housing delivers durability and robust heat dissipation, supporting long service life and lower maintenance costs in continuous operation. A 2-pole, S1 duty rating ensures stable, constant-speed operation for conveyors, crushers, and material handling equipment, translating into predictable process control and improved throughput. IE2 efficiency improves energy performance and reduces operating expenses over the motor’s life, with energy cost savings becoming tangible in long-term deployments. The top-terminator box enables easier electrical connections and faster installation, minimizing downtime during maintenance or retrofits. Combined with dimensionally compatible mounting and bearings (6316/C3), this motor offers straightforward alignment and reduced spares consumption. The Exdb and flameproof design supports compliance with strict mining regulations, while the compact frame and standard mounting simplify retrofits into existing lines.

Get a Quick Quote for a ABB 3GJM281210-AEG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM281210-AEG?

Enquire Now

FAQs

This motor uses a 280 frame with a cast-iron housing and a top termination box, making it compatible with existing 280-frame bases and common mounting designs. The 2-pole, S1 duty configuration supports continuous operation in conveyors and crushers. For retrofit projects, confirm shaft alignment, bearing fit (6316/C3), and clearance to avoid interference with nearby components.

Key specs include IE2 efficiency class, voltage code E, IP66 enclosure, and Exdb explosion protection. The motor is designed for 3-phase power with a 2-pole configuration, suitable for continuous duty (S1) in demanding environments, and operates at ambient 40 °C with up to 1000 m altitude.

Yes. The model features Exdb explosion protection and flameproof design, making it appropriate for mining environments where hazardous atmosphere classifications apply. Its IP66 rating further ensures ingress protection in dusty or wet mining areas, supporting safer operation of conveyors, crushers, and material handling.

Plan for top-mounted terminal connections, 280 frame mounting, and alignment with 6316/C3 bearings. Ensure adequate clearance for heat dissipation, verify ambient temperature does not exceed 40 °C in operation, and confirm the motor’s top-termination box location aligns with the control panel or junction box to minimize wiring length and simplify maintenance.

IE2 efficiency lowers energy costs during long-running cycles common in mining and processing plants, improving total cost of ownership. Exdb flameproofing reduces risk and potential downtime from hazardous atmospheres. Combined with a cast-iron frame and robust bearings, this motor delivers longer service life and reduced maintenance cycles in harsh environments.