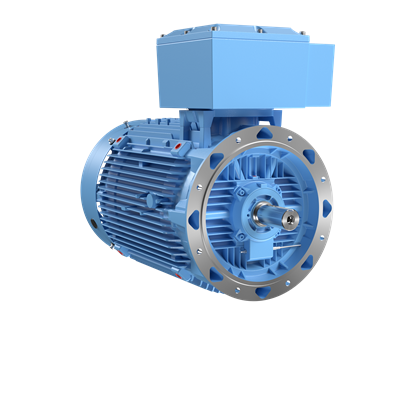

ABB 3GJM281210-ASG 3-Phase Squirrel Cage Motor - Exdb

Part Number: 3GJM281210-ASG

Quick Summary

ABB 3GJM281210-ASG is a 3-phase squirrel cage motor for demanding mining and flameproof duty in hazardous environments. Operators face downtime caused by harsh ambient conditions, insufficient explosion protection, and rising maintenance costs, which can disrupt production schedules. This motor combines Exdb flameproof protection, IP66 enclosure, and ICFL insulation to meet stringent safety and reliability requirements. With IE2 efficiency data across 50 Hz and 60 Hz, a robust 280 frame, and a cast-iron build, it delivers consistent torque while reducing energy consumption. In practice, its top-terminal box and precision bearings support reliable operation in remote mines and other challenging sites, lowering lifecycle risk and total cost of ownership.

Product Information

ABB Type Designation

M3JM 280SMA 2

Invoice Description

M3JM 280SMA 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 94.3 % | Partial Load (75%) 93.8 % | Partial Load (50%) 92.2 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.0 % | Partial Load (75%) 92.4 % | Partial Load (50%) 90.5 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

644 kg

Gross Weight

664 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Exdb flameproof protection and IP66 enclosure provide certified safety in hazardous areas. Business Impact: Reduces risk of ignition and protects equipment against washdowns, improving regulatory compliance and uptime. Application: Ideal for mining conveyors, hoists, and other heavy-duty drives in Group I environments. Feature: IE2 efficiency data at 50 Hz and 60 Hz delivers measurable energy savings. Business Impact: Lower operating costs over the motor’s life, especially under steady-state loads common in material handling. Application: Suitable for long-duty cycles in mining and process facilities where energy costs accumulate. Feature: 280 frame, Cast Iron frame and 6316/C3 bearings deliver rugged durability. Business Impact: Extended service life, fewer unscheduled maintenance events, and easier replacement cycles. Application: Harsh surroundings and frequent starts/stops in industrial plants. Feature: Exd/Exdb flameproof design with Group I suitability and 2-pole operation. Business Impact: Enables safe operation in potentially explosive atmospheres while maintaining high starting torque. Application: Mining equipment, crushers, and material handling systems operating in hazardous zones. Feature: Top terminator box location and IMB3 IM1001 mounting class support easy installation and alignment. Business Impact: Simplifies field wiring and maintenance, reducing installation time and downtime. Application: New builds and retrofit projects in remote facilities with limited service access. Industry context: The combination of robust mechanical construction (Cast Iron 280 frame, 6316/C3 bearings), protective features (IP66, Exdb), and energy-conscious IE2 performance aligns with modern mine automation strategies, ensuring compatibility with standard drives and control systems while delivering predictable, long-lasting performance.

Get a Quick Quote for a ABB 3GJM281210-ASG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM281210-ASG?

Enquire Now

FAQs

Install with the Top Terminator Box as specified to simplify field wiring and reduce install time. The 280 frame with Cast Iron construction fits standard baseplates and bolt patterns, and the 2-pole design aligns with common 50/60 Hz drives. Ensure Exdb protection and IP66 enclosure are maintained during assembly, and verify the ambient limits (40 °C, 1000 m) are respected for optimal performance.

At 50 Hz, Full Load efficiency is 94.3%, with 75% and 50% partial loads at 93.8% and 92.2% respectively. At 60 Hz, Full Load efficiency is 93.0%, with 75% and 50% partial loads at 92.4% and 90.5% respectively. These figures translate to meaningful energy savings in continuous operation typical of mining conveyors and hoists, contributing to lower lifecycle costs and improved sustainability.

Yes. The Exdb flameproof protection combined with IP66 enclosure (dust and water ingress protection) makes it suitable for hazardous-area mining applications (Group I). The 2-pole IE2 rated motor operates under S1 duty, delivering reliable torque in mining conveyors, crushers, and other heavy-duty drives while meeting safety standards.

The motor uses a Cast Iron frame with a robust 6316/C3 bearing arrangement and IMB3 IM1001 mounting class, designed for rugged service. Routine checks should include bearing condition, insulation integrity, and enclosure seals to preserve IP66 protection. The top terminator box simplifies wiring during maintenance, and the Exd/Exdb protection reduces the risk of corrosion-related failures in harsh environments.

Key benefits include strong energy efficiency (IE2), high reliability in hazardous zones (Exdb IP66), and reduced downtime due to robust mechanical design. Its 280 Cast Iron frame and top-term box simplify installation and maintenance, delivering lower lifetime costs, improved safety compliance, and consistent performance across mining applications and heavy-duty drives.