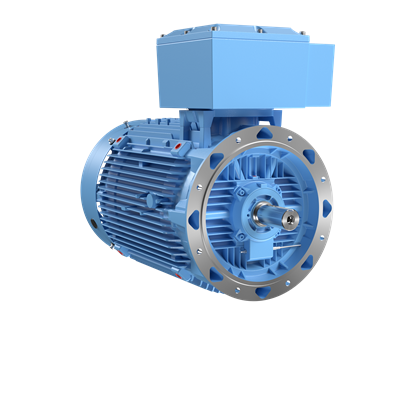

ABB 3GJM281210-BSG 3-Phase squirrel cage motor - Flameproof Exd mining motor

Part Number: 3GJM281210-BSG

Quick Summary

ABB 3GJM281210-BSG 3-Phase squirrel cage motor is a robust drive solution for mining and heavy industrial plants. Engineers often face hazardous location constraints, strict compliance, and long commissioning times that erode uptime. With IP66 protection, Exdb flameproof certification, and IC411 insulation, this motor is engineered for safe operation in explosive atmospheres. Designed for IE2 efficiency and a solid cast-iron frame, it reduces energy costs while enabling easier installation and maintenance in demanding environments. This approach aligns with lifecycle cost targets and safety requirements, delivering reliable performance across global operations.

Product Information

ABB Type Designation

M3JM 280SMA 2

Invoice Description

M3JM 280SMA 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 94.3 % | Partial Load (75%) 93.8 % | Partial Load (50%) 92.2 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.0 % | Partial Load (75%) 92.4 % | Partial Load (50%) 90.5 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

644 kg

Gross Weight

664 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Exdb flameproof protection provides a heightened level of safety in potentially explosive atmospheres. Business Impact: Reduces risk, simplifies regulatory compliance, and minimizes downtime due to ignition-related incidents. Application: Mining and other hazardous locations where explosion protection is mandatory. Feature: IP66 ingress protection keeps dust, water, and wash-down corrosives at bay, extending motor life in tough plants. Business Impact: Lower maintenance costs and longer service intervals, improving overall equipment effectiveness (OEE). Application: Underground and surface mining equipment, cement plants, and chemical processing lines. Feature: IE2 efficiency class delivers measurable energy savings under full and partial load. Business Impact: Lower operating costs and greener operation, helping meet sustainability goals and TCO targets. Application: Heavy-load drives and continuous duty conveyors in mining and material handling. Feature: Cast iron frame and bearing arrangement (6316/C3) deliver rugged durability and long service life in harsh environments. Business Impact: Higher MTBF, reduced spare-part frequency, and fewer maintenance interventions. Application: Harsh industrial settings with exposure to vibrations and temperature fluctuations. Feature: Top terminator box location and standardized 280 frame support quick installation and straightforward service output. Business Impact: Shorter downtime during maintenance, easier field wiring, and compatibility with existing Exd protection schemes. Application: Retrofit projects and new builds in mines, steel mills, and process plants. Feature: 2-pole design, 1000 m altitude and 40 °C ambient capability expand operating envelopes for global deployments. Business Impact: Broad geographic applicability with reliable performance and minimal derating. Application: International mining sites and remote facilities requiring robust environmental tolerance. Overall, the ABB 3GJM281210-BSG integrates flameproof safety, protective enclosure, and efficiency gains to deliver predictable uptime, simpler compliance, and lower total cost of ownership in demanding industrial settings.

Get a Quick Quote for a ABB 3GJM281210-BSG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM281210-BSG?

Enquire Now

FAQs

Install requires proper Exd-rated wiring, top-entry terminal box alignment, and adherence to IP66 sealing practices. Ensure supply uses Voltage Code S and that mounting is on a stable, vibration-damped base. The 280 frame and cast iron housing support secure mounting, while the Exdb protection provides explosion protection in hazardous areas. Regular checks of bearing condition (6316/C3) and insulation (ICLF) maintain safety margins.

Yes. This motor is designed for IE2 efficiency, with a 2-pole configuration suitable for steady-speed or fixed-speed drives. Its voltage code S simplifies integration with standard mining power systems, and the motor’s robust frame supports reliable operation when paired with VFDs or constant-speed drives, while maintaining compliance with S1 duty in demanding loads.

Key certifications include Exdb flameproof protection for hazardous atmospheres, IP66 ingress protection, and IC411 insulation class. The motor is suitable for mining and heavy industry, supports S1 duty, and aligns with high safety and reliability standards essential for underground operations and surface plants alike.

Best-suited for flameproof mining motors and other hazardous-location drives, especially where rugged cast iron construction, IP66 protection, and Exd certification are required. Use cases include conveying, extraction, pumps, and fans in mines, steel plants, and chemical facilities where explosion protection and durable performance are critical.

Expect higher uptime and lower maintenance costs due to the rugged 6316/C3 bearings, cast iron frame, and long insulation life (ICLF). The motor’s reliable Exd protection reduces downtime in hazardous zones, while IE2 efficiency lowers energy costs. With predictable service intervals and compatible spare parts, the total cost of ownership improves over the motor’s lifecycle.