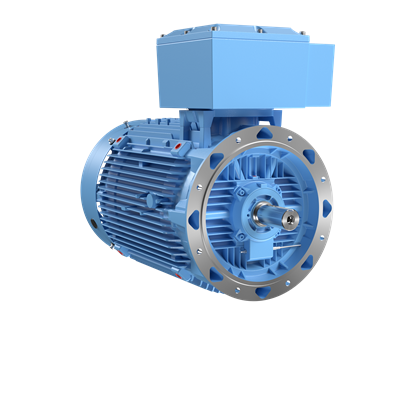

ABB 3GJM281230-ASG 3-Phase Squirrel Cage Motor - Exdb

Part Number: 3GJM281230-ASG

Quick Summary

ABB 3GJM281230-ASG is a 3-phase squirrel cage motor designed for heavy-duty mining applications with flameproof Exd protection. In hazardous sites, equipment must withstand dust, moisture, and explosive atmospheres while delivering reliable performance. This motor meets IP66 sealing, Exdb flameproof protection, and ICFL insulation, with IE2 efficiency at 50 Hz and IE1 at 60 Hz, delivering a balance of safety and energy savings. With a rugged cast-iron frame and robust bearings, it provides long service life in challenging environments. For industrial motors used in mining and other high-risk operations, this model supports compliance and operational uptime while supporting cost-effective maintenance and retrofit programs.

Product Information

ABB Type Designation

M3JM 280SMC 2

Invoice Description

M3JM 280SMC 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 95.1 % | Partial Load (75%) 95.1 % | Partial Load (50%) 94.2 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 94.0 % | Partial Load (75%) 93.6 % | Partial Load (50%) 92.3 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

744 kg

Gross Weight

764 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Exdb flameproof protection enables safe operation in hazardous zones, reducing risk of ignition and ensuring regulatory compliance. Business Impact: lowers safety-related downtime and protects personnel and assets. Application: suitable for mining conveyors, hoists, and process equipment where explosion protection is mandatory. Feature: IP66 ingress protection delivers excellent washdown and dust resistance, extending service intervals and reducing maintenance costs. Application: ideal for wet or dusty environments common in mining and heavy industry. Feature: IE2 efficiency at 50 Hz (and IE1 at 60 Hz) lowers energy consumption, delivering meaningful lifecycle cost savings and carbon footprint reductions. Application: retrofit or new installations seeking energy optimization without compromising torque. Feature: Cast-iron frame, 280 frame size, and 744 kg net weight provide exceptional rigidity and vibration damping, improving reliability in shock-loaded operations. Application: heavy-duty mining drives and hoisting systems where uptime is critical. Feature: Bearing arrangement 6316/C3 with IMB3 IM1001 mounting and a top termination box location facilitates robust mounting, simpler installation, and easier maintenance in confined spaces. Application: industry-standard mounting for rugged environments with long service intervals. Feature: Altitude up to 1000 m and ambient temperature up to 40 C ensure consistent performance in elevated or hot sites, reducing the need for site-specific accounts and replacements. Application: installations in mining sites with challenging climate or geography. Feature: Ex-protection and insulation combination (Exdb, ICFL) provides multi-layer safety and reliability for continuous operation (S1), supporting long-running duty cycles. Application: process lines and conveyors requiring continuous operation at steady loads. Feature: 2-pole, single-speed configuration aligns with common drive systems, enabling straightforward integration with existing electrical infrastructure. Application: retrofits and new builds in mining and heavy industry seeking dependable performance with familiar control strategies.

Get a Quick Quote for a ABB 3GJM281230-ASG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM281230-ASG?

Enquire Now

FAQs

When installing in hazardous zones, ensure Exdb flameproof protection is maintained, and use the top termination box for easy access. The IMB3 IM1001 mounting configuration and a 280 frame size fit standard layouts. Consider ambient temperature (up to 40 C) and altitude (up to 1000 m) to maintain performance and ensure IP66 protection is preserved during washdown and dust exposure.

The motor combines Exdb flameproof protection with IP66 ingress protection, meaning it is designed for explosive atmospheres and harsh outdoor or underground conditions. It carries ICFL insulation and IE2 efficiency at 50 Hz (and IE1 at 60 Hz), delivering safe operation, regulatory compliance, and reduced energy costs in mining and other heavy industries.

At 50 Hz the product meets IE2 efficiency, offering significant energy savings over standard IE1 designs. At 60 Hz, the class is IE1, still providing reliable performance for variable-frequency drives. This profile supports improved operating costs in continuous-duty applications like conveyors and hoists in mining operations.

Key specs to confirm include frame size 280 and 2-pole design, Exdb flameproof protection, IP66 rating, IE2 at 50 Hz (IE1 at 60 Hz), insulation ICFL, weight around 744 kg (net), and the cast iron frame. Also verify altitude and ambient conditions (1000 m and 40 C) and the terminal box location (Top) for proper installation.

Robust Exdb protection and IP66 sealing reduce unplanned downtime and maintenance frequency in hazardous environments. The IE2 efficiency at 50 Hz lowers energy costs over the motor’s life, while the heavy-duty cast-iron frame and bearings deliver high reliability under shock loads. Together, these features support longer mean time between repairs (MTBF) and a lower total cost of ownership.