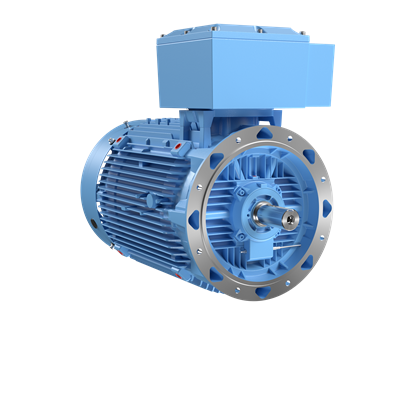

ABB 3GJM281230-BEG 3-Phase Motor - Exdb IP66 IE2

Part Number: 3GJM281230-BEG

Quick Summary

ABB 3GJM281230-BEG 3-Phase motor is a rugged, explosion-protected solution designed for mining, chemical, and heavy industry environments. Operators often struggle with downtime caused by dust ingress, heat, and moisture; this motor is built to withstand harsh setups while maintaining dependable performance under full-load conditions. With Exdb flameproof protection, IP66 sealing, and IE2 efficiency, it meets key safety and energy standards essential for regulated sites. Designed for high-altitude operation and demanding ambient temperatures, it helps reduce lifecycle costs while enabling reliable continuous-duty operation in demanding installations. This model ships from Finland (FI) and is suitable for demanding industrial applications where safety, reliability, and efficiency are non-negotiable.

Product Information

ABB Type Designation

M3JM 280SMC 2

Invoice Description

M3JM 280SMC 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 95.1 % | Partial Load (75%) 95.1 % | Partial Load (50%) 94.5 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

E

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

744 kg

Gross Weight

764 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature → Business Impact → Application: Exdb flameproof protection and IP66 sealing reduce ignition risk and ingress in hazardous environments, delivering safer operation and lower maintenance costs for mining conveyors and processing plants. This directly supports compliance with hazardous-area standards while minimizing unplanned downtime. Feature → Business Impact → Application: Cast iron frame (280) provides exceptional rigidity and heat dissipation, translating to reduced vibration, longer bearing life, and lower shaft misalignment risk in long-running drives such as crushers, mills, and pump stations. Feature → Business Impact → Application: IE2 efficiency rating (Full Load 95.1%) enables meaningful energy savings on continuous-duty S1 operation, lowering operating expenses in large-scale material handling and mineral processing facilities. Feature → Business Impact → Application: IC411 insulation, ICLF class, and 40 °C ambient tolerance enable reliable performance at up to 1000 m altitude, ensuring uptime in high-altitude or hot-site locations. Feature → Business Impact → Application: IMB5 IM3001 mounting, 2-pole design, and top terminator box location simplify installation and serviceability, reducing commissioning time and enabling quicker maintenance in harsh environments. Feature → Business Impact → Application: Bearing specification 6316/C3 with NDE compatibility enhances durability under heavy loads and misalignment, supporting long service intervals for conveyors and extraction equipment. Feature → Business Impact → Application: Customs tariff and origin details from Finland ensure traceability and supply-chain confidence for large-scale project bids and regulated sectors. The combination of Exdb protection, IP66, and robust mechanicals makes this motor a trusted choice for mining, chemical processing, and other demanding industries where reliability and safety drive throughput and ROI.

Get a Quick Quote for a ABB 3GJM281230-BEG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM281230-BEG?

Enquire Now

FAQs

For safe installation in hazardous locations, place the motor with Exdb protection and IP66 sealing in a sheltered, clean area where the top termination box remains accessible. Use IMB5 IM3001 mounting, ensure correct alignment with a rigid foundation, and verify ambient temperature and altitude limits (up to 1000 m, 40 °C). Wiring should follow Ex-rated safety practices and local wiring codes.

The motor is rated IE2 with Full Load efficiency around 95.1%. This level of efficiency reduces energy consumption in continuous-duty service (S1), delivering lower operating costs for conveyors, pumps, and processing lines while maintaining reliable torque and starting performance under full-load conditions.

Yes. The Exdb flameproof protection, IP66 ingress protection, 280 frame with cast iron construction, and IMB5 mounting make it well-suited for mining conveyors, slurry pumps, and process pumps where dust, moisture, and potential explosions are concerns. Its robust bearings and insulation handle demanding industrial duty cycles while maintaining longevity and safety.

This motor features Exdb explosion protection, IP66 rating for dust and water ingress protection, IC411 insulation class, and ICLF insulation. It is designed for high reliability in hazardous locations and harsh environments, with a 2-pole high-speed design and top-terminator box for convenient installation and service.

Expect reduced downtime due to robust cast-iron construction, reliable IMB5 mounting, and high IP/Ex protection. The IE2 efficiency improves energy costs in continuous operation, while low-maintenance bearings (6316/C3) and rated Altitude support limit service intervals. Overall, this motor lowers total cost of ownership in mining and heavy industry deployments.