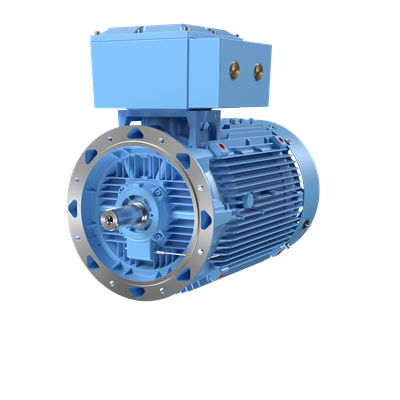

ABB 3GJM281230-BLK 3-Phase Squirrel Cage Motor - Exdb

Part Number: 3GJM281230-BLK

Quick Summary

The 3GJM281230-BLK flameproof mining motor is a 90 kW, 1000 V, 50 Hz 2-pole drive designed for hazardous underground environments. Operators often struggle with equipment downtime and unsafe emissions when flameproof ratings are insufficient. This motor mitigates those challenges with a cast-iron frame, Exdb flameproof protection, and IP66 enclosure, plus insulation suitable for 40 °C ambient. It delivers dependable performance at up to 1000 m elevation while maintaining high efficiency. Designed for IMB5/IM3001 mounting, the unit integrates smoothly with mining conveyors, pumps, and hoists. This combination improves mean time between repair and overall uptime.

Product Information

ABB Type Designation

M3JM 280SMC 2

Invoice Description

M3JM 280SMC 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM3__M3JM_IE3_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Medium Description

90kW, 2 Poles, Frame Size 280, 3 Phases, 1000V, 50Hz, IP66 Enclosure, IMB5/IM3001 Mounting (3GJM281230-BLK)

Short Description

90kW, 2P, Frame Size 280, 3PH, 1000V, 50Hz, IP66, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

--

Input Voltage (Uin)

1000 V

Frequency (f)

50 Hz

Output Power

90 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 96.4 % | Partial Load (75%) 96.5 % | Partial Load (50%) 96.0 %

IP Class

IP66

Insulation Class

ICLH

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

L

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1088 mm

Product Net Height

762 mm

Product Net Width

481 mm

Product Net Weight

856 kg

Gross Weight

876 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Exdb flameproof protection provides proven safety in hazardous zones, supporting regulatory compliance and safer maintenance in underground operations. The rugged mechanical design, cast-iron frame and IP66 enclosure resist dust, water ingress, and vibration while simplifying field service through easier terminal access and fewer vulnerabilities in hostile environments. With Exdb, operators can meet mining safety standards without sacrificing uptime. IE3/IE4 efficiency delivers measurable energy savings and lower heat generation in continuous-duty operation, improving uptime and reducing cooling load in compact underground plants. The 90 kW output at 1000 V aligns with common mine drive systems, enabling immediate plug-in compatibility and predictable performance across rotating equipment. This efficiency advantage translates to lower operating costs year over year. IP66 enclosure and insulation class IC LH (IC411) are tuned for high-temperature environments up to 40 °C and elevations up to 1000 m. The design tolerates dust, moisture and thermal swings typical of surface installations near shafts while maintaining insulation integrity during long-duty cycles. The result is a robust motor that maintains torque and speed under demanding loads. Electrical configuration D, 1000 V input, 50 Hz, 90 kW output, and 2 poles provide a compact, high-power package for heavy conveyors and hoists. Operating in S1 duty, the motor sustains full-load performance with consistent efficiency across varying loads, while the 6316/C3 bearings support long service life in vibration-prone underground environments. The D‑end top terminator box streamlines field wiring. Mechanical design features cast iron frame size 280, with IMB5/IM3001 mounting options that fit ABB and third-party assemblies. Bearing arrangement and seals are selected for extended life in mining operations, and the product is offered with a minimal order quantity of one piece for rapid deployment. Overall, it provides a rugged, globally available solution for hazardous-location drives. This design supports easy replacement and predictable maintenance cycles, helping operations plan outages and budget maintenance more effectively.

Get a Quick Quote for a ABB 3GJM281230-BLK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM281230-BLK?

Enquire Now

FAQs

The motor uses a D connection configuration and is designed for 1000 V 3-phase supply at 50 Hz, facilitating direct integration with standard mine switchgear. With IP66, Exdb flameproof protection, and a D-end top terminator box, it supports straightforward wiring, safe installation in hazardous areas, and compatibility with IMB5/IM3001 mounting schemes common in mining drives.

You can expect 90 kW output at 1000 V and 50 Hz with a two-pole design. The motor delivers high efficiency, classified IE4 in full-load conditions around 96.4%, which translates to reduced energy consumption and cooler operation during continuous duty in mining conveyors and hoists.

Yes. Rated for ambient temperatures up to 40 °C and elevations up to 1000 meters, the motor uses IP66 and ICLH insulation to maintain performance in challenging climates. It is built to withstand dust, moisture, and thermal cycling typical of deep-well and open-pit mining environments.

Key certifications include Exdb flameproof protection for hazardous zones, IP66 enclosure protection, and ICLH insulation with IC411 data. The motor supports IMB5/IM3001 mounting and D-end top wiring, aligning with industry safety and performance standards for mining applications.

With 6316/C3 bearings and a cast-iron frame, the motor is built for long service life in vibration-prone environments. The IE4 efficiency reduces operating costs, while robust protection and mounting options minimize downtime. Plan APUs around 1-piece minimum orders for rapid deployment and predictable maintenance cycles.