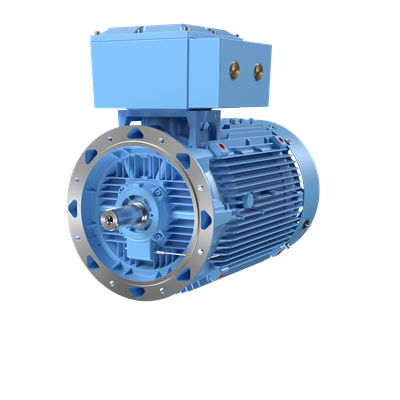

ABB 3GJM282230-BEL Flameproof IE3 Mining Motor - Exdb/IP66

Part Number: 3GJM282230-BEL

Quick Summary

3GJM282230-BEL Flameproof IE3 mining motor is a 90 kW, 500 V drive designed for harsh mining environments. It addresses downtime and energy costs by delivering reliable performance where ignition risk and dust are constant concerns. The design incorporates Exdb flameproof protection, IP66 sealing, and IC411 insulation to meet safety and reliability expectations in hazardous locations. With IMB5/IM3001 mounting compatibility and a robust cast-iron frame, this motor provides a practical, long-life solution for underground and surface mining operations. In addition to premium IE3 efficiency, it supports consistent output across shift operations, delivering measurable cost savings and equipment uptime for procurement and maintenance teams alike.

Product Information

ABB Type Designation

M3JM 280SMC 4

Invoice Description

M3JM 280SMC 4

Product Name

3-Phase squirrel cage motor

Product Type

5JM3__M3JM_IE3_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Medium Description

90kW, 4 Poles, Frame Size 280, 3 Phases, 500V, 50Hz, IP66 Enclosure, IMB5/IM3001 Mounting (3GJM282230-BEL)

Short Description

90kW, 4P, Frame Size 280, 3PH, 500V, 50Hz, IP66, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

--

Input Voltage (Uin)

500 V

Frequency (f)

50 Hz

Output Power

90 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE3 | Full Load (100%) 95.2 % | Partial Load (75%) 95.5 % | Partial Load (50%) 95.2 %

IE Class Data (60 Hz)

IE Class IE3 | Full Load (100%) 95.4 % | Partial Load (75%) 95.2 % | Partial Load (50%) 94.2 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S1

Voltage Code

E

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1088 mm

Product Net Height

762 mm

Product Net Width

481 mm

Product Net Weight

829 kg

Gross Weight

849 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Exdb flameproof protection combined with IP66 enclosure. Business Impact: Ensures operation in hazardous atmospheres with reduced risk of ignition and environmental ingress, supporting regulatory compliance. Application: Suitable for mining conveyors and crushers in underground mines where safety certification is mandatory. Feature: IE3 premium efficiency at 90 kW. Business Impact: Lowers energy consumption and running costs over the motor’s lifecycle, improving total cost of ownership. Application: Continuous 50 Hz operation in surface processing plants and underground facilities seeking energy optimization. Feature: 4-pole, 90 kW at 500 V with D-connection, IC411 insulation. Business Impact: Consistent torque characteristics and reliable thermal management for steady production lines. Application: Heavy-duty drives and material handling in harsh environments. Feature: IMB5/IM3001 mounting compatibility and D-End top terminator. Business Impact: Flexible installation options reduce retrofit complexity and spare part diversity. Application: Retrofit projects and new builds requiring quick, vibration-resistant mounting. Feature: Cast iron frame (Frame Size 280) with 6316/C3 bearings. Business Impact: High durability, vibration tolerance, and extended service life, lowering maintenance frequency. Application: Mining mills, fans, and pumps subject to heavy mechanical stresses. Feature: Altitude up to 1000 m and ambient 40 °C with IC411 insulation. Business Impact: Thermal resilience and reliable performance in diverse mining sites, simplifying site-specific approvals. Application: Remote or high-altitude operations and hot environments where cooling capacity is critical.

Get a Quick Quote for a ABB 3GJM282230-BEL

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM282230-BEL?

Enquire Now

FAQs

The 3GJM282230-BEL supports IMB5/IM3001 mounting with a D-End top terminator and a 4-pole configuration in a frame size 280. It uses a 500 V, 50 Hz supply and is designed for easy retrofit or integration into new builds, helping minimize installation time and spare-part diversity while ensuring vibration resistance and secure alignment with existing Equipment. This makes it suitable for conveyors, pumps, and fans in mining environments.

This motor is IE3 premium efficiency, delivering strong energy savings on continuous duty. It features Exdb flameproof protection and IP66 enclosure for hazardous locations, along with IC411 insulation and a 4-pole design. These attributes ensure reliable torque, robust thermal performance, and compliance with safety standards typical in mining and processing settings.

Yes. The ABB 3GJM282230-BEL is designed for mining environments, offering flameproof Exdb protection, IP66 sealing, and robust mechanical construction. Its S1 duty rating and mounting options make it appropriate for long, continuous operation in both underground and surface applications, including conveyors, crushers, and other heavy-duty equipment in harsh environments.

The motor provides Exdb flameproof protection and IP66 ingress protection, coupled with IC411 insulation and S1 duty. It is engineered for hazardous locations in mining and industrial settings, aligning with common regulatory requirements for explosion protection and equipment safety while offering reliable performance across diverse ambient conditions.

Expect reduced downtime due to rugged cast-iron construction, high bearing reliability (6316/C3), and durable IMB5/IM3001 mounting. Energy savings from IE3 efficiency further improve ROI, while the flameproof and IP66 protection minimize intervention needs in harsh environments. Regular checks on bearings and cooling, plus adherence to installation guidelines, will maximize lifecycle and performance.