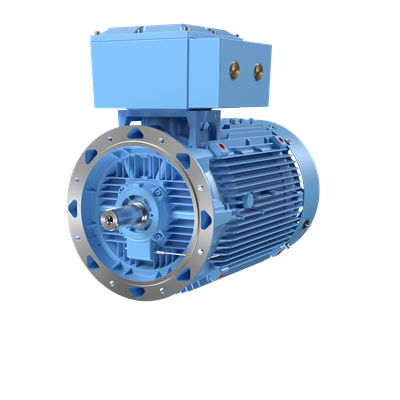

ABB 3GJM283230-BEL Flameproof IE3 Mining Motor IP66

Part Number: 3GJM283230-BEL

Quick Summary

ABB 3GJM283230-BEL Flameproof IE3 mining motor is a 55 kW, three‑phase solution engineered for hazardous zone applications such as underground mining. Operators struggle with preventing unplanned downtime while meeting explosion‑proof requirements and strict efficiency targets. This motor addresses both by delivering premium IE3 efficiency, Exdb flameproof protection, and IP66 sealing for harsh environments. With a frame size 280 and IMB5/IM3001 mounting, installation is straightforward in confined spaces. Built to operate at up to 1000 m altitude and 40 °C ambient, it combines reliability with regulatory compliance. The design integrates robust bearings, 6 poles, and a D‑configuration connection for adaptable installation, helping minimize lifecycle costs while ensuring safe, compliant operation in demanding facilities.

Product Information

ABB Type Designation

M3JM 280SMC 6

Invoice Description

M3JM 280SMC 6

Product Name

3-Phase squirrel cage motor

Product Type

5JM3__M3JM_IE3_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015230

Medium Description

55kW, 6 Poles, Frame Size 280, 3 Phases, 500V, 50Hz, IP66 Enclosure, IMB5/IM3001 Mounting (3GJM283230-BEL)

Short Description

55kW, 6P, Frame Size 280, 3PH, 500V, 50Hz, IP66, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

--

Input Voltage (Uin)

500 V

Frequency (f)

50 Hz

Output Power

55 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE3 | Full Load (100%) 94.1 % | Partial Load (75%) 94.3 % | Partial Load (50%) 93.8 %

IE Class Data (60 Hz)

IE Class IE3 | Full Load (100%) 94.5 % | Partial Load (75%) 94.5 % | Partial Load (50%) 93.5 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Type of Duty

S1

Voltage Code

E

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1088 mm

Product Net Height

762 mm

Product Net Width

481 mm

Product Net Weight

806 kg

Gross Weight

826 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Flameproof Exdb protection provides explosion‑safe operation in hazardous zones, reducing risk and enabling compliant use in underground environments. This translates into lower downtime costs and safer maintenance windows, supporting production continuity in mining sites. The IE3 premium efficiency rating delivers tangible energy savings, improving total cost of ownership over the motor’s life while meeting increasingly strict regulatory requirements. In practice, operators observe reduced electricity bills at full and partial loads, especially during long duty cycles common in mining operations. The IP66 enclosure and rugged cast‑iron frame withstand vibrational stress, dust, and ingress, simplifying installation in harsh plant corners and reducing enclosure‑related failures. Frame size 280 with IMB5/IM3001 mounting offers a compact footprint and straightforward alignment with existing motor bases. The Exdb protection and IC411 insulation class, combined with a 1000 m altitude rating and 40 °C ambient tolerance, ensure stable performance across mining facilities and surface sites. Finishing details such as bearing 6316/C3 and D‑configured connections support reliable service in continuous duty (S1) applications, while the D‑End top terminator box placement streamlines wiring and service access. These design choices reflect ABB’s focus on long‑life intelligence, minimizing unscheduled maintenance and optimizing uptime in demanding environments. Originating in Finland, this motor also aligns with high manufacturing standards and a robust supply chain for critical mining equipment.

Get a Quick Quote for a ABB 3GJM283230-BEL

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM283230-BEL?

Enquire Now

FAQs

For hazardous areas, follow ABB’s recommended Exdb flameproof installation practices, ensuring the D‑configuration wiring is verified and the terminator box is accessible from the D‑End top. Use IMB5/IM3001 mounting to align with existing bases, maintain proper clearance for heat dissipation, and verify ambient conditions do not exceed 40 °C with elevations under 1000 m. Regular inspection of seals and cable entries is advised to preserve IP66 integrity.

IE3 efficiency reduces electrical losses during continuous duty, cutting energy consumption and lowering electric bills over the motor’s life. At 50 Hz, the data indicates Full Load efficiency near 94.1%, with favorable partial-load performance. In mining operations with long run times and high duty cycles, these savings compound, improving return on investment while helping meet regulatory energy targets.

Yes. The 3GJM283230-BEL is designed for IMB5/IM3001 mounting and includes a D‑End top terminator box, facilitating straightforward wiring in constrained underground spaces. Its 6-pole design provides a balance of starting torque and speed, while the 280 frame and cast‑iron construction support rugged underground service. However, confirm adapter compatibility with existing bases and ensure correct torque on mounting bolts during installation.

The motor carries IP66 enclosure protection for protection against dust and water ingress, Exdb flameproof protection for explosion‑risk environments, and IC411 insulation class to withstand higher temperatures. Together with IE3 efficiency and S1 duty, these certifications ensure compliance with safety and energy standards in mining and other hazardous installations.

Maintenance should emphasize periodic bearing inspection (6316/C3), seal checks, and electrical connection verification, especially after exposure to dust and vibration. The flameproof design minimizes ignition risks, while the robust IP66 enclosure reduces maintenance downtime due to ingress. ROI benefits arise from energy savings with IE3 efficiency, reduced downtime from durable construction, and predictable lifecycle costs in critical mining operations.